In the ever-evolving landscape of printing technology, UV DTF Transfers have emerged as a standout technique for producing vibrant prints with remarkable durability. Utilizing advanced UV printing technology, this method allows for the creation of custom apparel that features rich colors and intricate designs which are ideal for personalizing clothing and promotional products alike. Whether it’s on textiles, plastics, or other surfaces, UV DTF transfers guarantee lasting quality that can withstand the test of time. As consumers increasingly seek unique and sustainable options, the demand for these durable transfers continues to grow. Join us as we explore the extensive benefits and versatile applications of UV DTF transfers, and discover how they can elevate your printing projects to new heights.

As the printing industry embraces innovative techniques, Direct to Film (DTF) transfers utilizing UV technology are leading the charge in enhancing print quality across various products. This printing approach offers a myriad of applications, ranging from custom apparel to promotional items, enabling businesses to cater to specific customer preferences with ease. With the capability to produce eye-catching, high-resolution designs, DTF printing presents a unique solution for those looking to make a bold statement with their products. Additionally, its environmental benefits position UV DTF as a forward-thinking choice for conscientious companies. Discover how this advanced printing method invites creativity and sustainability into the realm of custom printing.

Understanding UV DTF Transfers

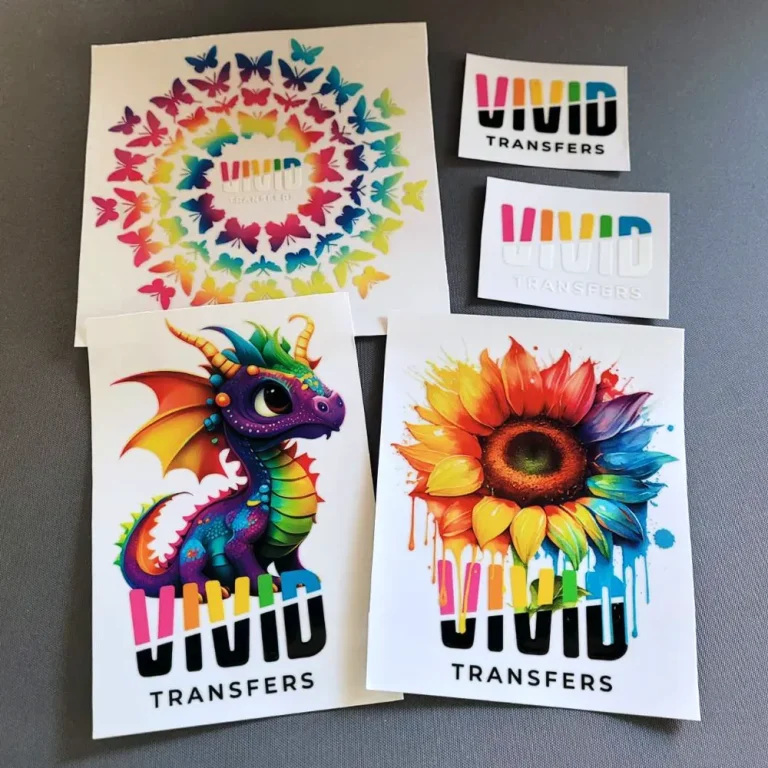

UV DTF transfers represent a significant leap in printing technology, merging the sheer versatility of direct-to-film printing with the unparalleled precision of UV inks. By utilizing UV printing technology, this method allows for detailed and vibrant artwork to be transferred onto a variety of surfaces. Ideal for custom apparel printing, the resulting products showcase a stunning array of colors and intricate designs that are sure to catch the eye. With a deep understanding of how UV DTF works, businesses can truly tap into the potential for personalization in their offerings.

The process begins with printing designs onto a special film using UV-cured inks. These inks harden under UV light, creating durable transfers that can easily adhere to numerous materials. This methodology is not only efficient but also paves the way for environmentally sustainable printing. As industries strive to adopt green practices, UV DTF transfers provide a promising alternative, emitting fewer volatile organic compounds (VOCs) than traditional methods, thus reducing negative environmental impacts.

The Benefits of UV DTF Printing Technology

Opting for UV DTF transfers comes with a multitude of benefits that cater to both businesses and consumers. One of the key advantages is the production of vibrant prints that stand the test of time. UV inks create a robust bond with various surfaces, making the prints resistant to fading, scratching, and peeling. For custom apparel, this means that vibrant graphics and colors will remain intact even after multiple washes, making it a practical choice for clothing items.

Additionally, UV DTF technology excels in cost-effectiveness, particularly for small batch productions. Unlike traditional screen printing methods that often require costly setups, UV DTF allows businesses to produce high-quality prints without significant overhead. This flexibility supports the growing demand for personalized products, as companies can easily adapt to market trends and consumer preferences without breaking the bank.

Applications of UV DTF Transfers in Custom Apparel

The versatility of UV DTF transfers significantly enhances the custom apparel sector. Fashion brands are increasingly turning to this technology to create unique designs that resonate with their target audience. Whether it’s custom t-shirts, hats, or sportswear, the ability to produce vibrant and personalized prints helps businesses stand out in a competitive market. Furthermore, with customization being a key trend, UV DTF allows for rapid prototyping and testing of new designs, enabling brands to respond quickly to consumer demands.

Moreover, UV DTF printing also opens up innovative possibilities for collaborations between brands and artists. This technology enables seamless integration of artistic designs into wearable art, thereby enriching the fashion landscape. The rich colors and detailed resolutions that UV DTF delivers can transform ordinary clothing pieces into statement items, appealing to consumers’ desires for individuality and self-expression.

Why Choose UV DTF for Promotional Items?

Promotional items play a crucial role in brand visibility and UV DTF transfers enhance this promotional strategy through high-impact and vibrant prints. Businesses can leverage the technology to create eye-catching products such as drinkware, tote bags, and corporate gifts that align with brand identity and leave a lasting impression on customers. The impressive quality of UV DTF prints ensures that these items not only attract attention but are also durable enough for everyday use.

Additionally, utilizing UV DTF for promotional products is an eco-friendlier alternative. As printed items often end up as waste, adopting sustainable printing methods like UV DTF aligns with modern sustainability goals, appealing to environmentally conscious consumers. This investment in responsible printing can enhance a brand’s reputation and drive consumer loyalty, ultimately translating into increased sales and stronger brand recognition.

Exploring Industrial Applications of UV DTF Transfers

The industrial sector benefits significantly from UV DTF transfers, especially in the realms of labeling and packaging. High-quality, durable labels produced from UV DTF technology meet stringent industry compliance while boasting vibrant graphics that capture attention. Companies can use this technology to create custom labels and packaging solutions that not only fulfill operational requirements but also enhance product appeal. The ability to print on various substrates expands possibilities, allowing for innovative packaging designs that can differentiate products on crowded shelves.

Moreover, as industries evolve and require more customized solutions, UV DTF transfers provide a pathway to fulfilling these needs. From small-batch production to large-scale deployments, businesses can efficiently manage their printing requirements without sacrificing quality or speed. This adaptability positions UV DTF as a preferred choice for companies looking to enhance their branding through high-quality industrial applications.

The Future of UV DTF Transfers and Sustainable Printing

As the printing industry continues to evolve, UV DTF technology holds great promise for the future of sustainable printing. With advancements in printing equipment and inks, the ability to produce high-quality, eco-friendly prints is becoming increasingly attainable. Companies are consistently seeking solutions that minimize environmental impact, and UV DTF’s reduced VOC emissions align with these initiatives. The continued development in UV DTF technologies reflects a shift towards greener practices, making it a frontrunner in the quest for sustainable production methods.

Looking ahead, we can anticipate that as consumer demand for personalized and eco-friendly products grows, UV DTF technology will adapt to meet these challenges. Innovations in speed, color accuracy, and print durability will redefine what is possible in printing, empowering businesses to enhance their offerings while remaining mindful of environmental impacts. Embracing UV DTF transfers ensures that businesses can not only satisfy consumer preferences but also lead the charge toward a more sustainable future in printing.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers utilize UV printing technology to create vibrant, durable prints on various surfaces. The process involves transferring designs onto a film and then applying them to items like textiles and plastics. The UV-cured inks dry instantly under UV light, ensuring bright, long-lasting colors.

What benefits do UV DTF transfers offer for custom apparel printing?

UV DTF transfers provide several advantages for custom apparel printing, including vibrant colors, high detail, and exceptional durability. This technology allows for intricate designs that maintain their quality even after repeated wear, making it ideal for personalized clothing lines.

How do UV DTF transfers compare to traditional printing methods?

Compared to traditional printing methods, UV DTF transfers offer enhanced color vibrancy, durability, and versatility. UV printing technology allows for prints that resist fading, scratching, and peeling, and it can adapt to various substrates, making it a superior choice for businesses seeking quality and customization.

Are UV DTF transfers environmentally friendly?

Yes, UV DTF transfers are considered a more sustainable printing option. They typically emit fewer volatile organic compounds (VOCs) than traditional methods, contributing to greener practices in the printing industry while still delivering high-quality, durable prints.

What types of products can be made using UV DTF transfers?

UV DTF transfers can be applied to a wide range of products, including custom apparel, promotional items like bags and drinkware, industrial labels, and artistic crafts. This versatility makes UV DTF a popular choice for various applications across different industries.

What recent advancements are being made in UV DTF printing technology?

Recent advancements in UV DTF printing technology focus on improving speed, color accuracy, and overall print quality. Newer printers are being developed that can significantly reduce turnaround times, catering to the increasing demand for high-quality, customizable products in the market.

| Key Point | Details |

|---|---|

| What is UV DTF Printing? | UV DTF transfers utilize UV printing technology to apply designs onto film, which can then be transferred to various surfaces including textiles and plastics. |

| Key Benefits | 1. Vibrant Colors and High Detail: UV inks produce bright, high-resolution images. 2. Durability: UV-cured inks are resistant to fading and wear. 3. Versatility: Adaptable to many surfaces, including apparel and industrial labeling. 4. Environmentally Friendly: Lower VOC emissions compared to traditional methods. 5. Cost-Effective for Short Runs: Ideal for small batches without high setup costs. |

| Applications of UV DTF Transfers | 1. Custom Apparel: Creation of personalized clothing. 2. Promotional Items: Customization of bags and drinkware. 3. Industrial and Packaging: High-quality labels and packaging solutions. 4. Arts and Crafts: Unique designs for personalized artwork. |

| Recent Developments | Recent advancements in UV DTF technology have improved speed and print quality, catering to increasing consumer demand for customization. |

Summary

UV DTF transfers represent a progressive advancement in printing technology, melding quality with efficiency and sustainability. This innovative method allows businesses to produce exceptional, durable prints across a wide array of substrates, fulfilling the growing demand for personalized products. The combination of vibrant colors and resilience makes UV DTF transfers an ideal choice for many applications, from custom apparel to promotional items. As UV DTF technology continues to evolve, it is set to redefine the standards of print quality and adaptability, offering exciting opportunities for the future of creativity in various industries. By investing in UV DTF transfers, companies can stay ahead in a competitive market, delivering unique, high-quality solutions that resonate with consumers.