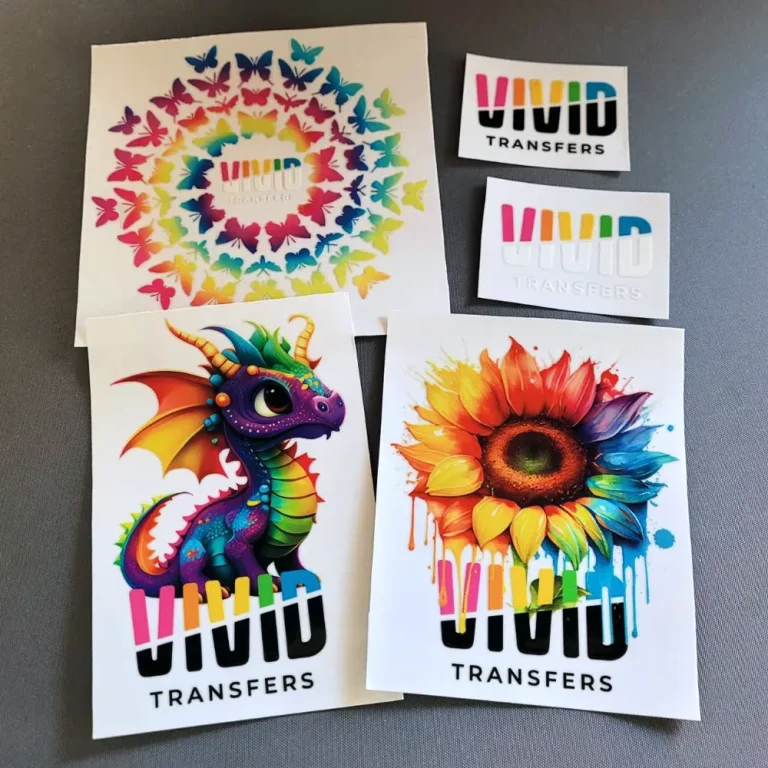

In the fast-evolving landscape of modern printing technology, UV DTF transfers are carving out a niche for themselves as a revolutionary solution for custom printing needs. These transfers leverage advanced UV printing technology to deliver benefits that stand out in quality and durability, ensuring that vibrant prints remain intact over time. Businesses are realizing the cost-effective printing advantages of UV DTF transfers, which allow for on-demand production without the waste associated with traditional methods. With their versatile applications across various substrates—from textiles to metal—UV DTF transfers are reshaping the possibilities for designers and manufacturers alike. This article delves into how these innovative printing solutions are enhancing production efficiency and meeting the diverse needs of today’s marketplace.

UV DTF printing, also known as Direct-to-Film printing with ultraviolet curing, symbolizes a leap forward in personalized print technology. This method is distinguished not just by its rapid production capabilities but also by the durability of its outputs, providing businesses with customizable items that are built to withstand the test of time. From promotional products to unique art pieces, the breadth of materials that UV DTF can be applied to expands creative potential significantly. As companies seek more cost-effective options without compromising quality, the rise of UV printing solutions addresses these demands effectively. With innovations constantly reshaping the industry, UV DTF transfers continue to be a cornerstone of modern custom printing.

Understanding UV DTF Printing Technology

UV DTF (Direct-to-Film) printing is a cutting-edge technology that harnesses the power of ultraviolet light to cure ink as it is printed onto a special film. This method stands out in the landscape of printing technologies for its ability to produce high-quality, vibrant prints on a vast array of materials. From textiles and glass to ceramics and metal, UV DTF’s versatility is unmatched. The innovative process not only enhances the aesthetic appeal of printed products but also broadens the scope of creative possibilities for designers and manufacturers alike.

The mechanics of UV DTF printing involve a series of precise steps—beginning with the digital design, progressing to ink application on the film, and culminating with a powerful UV light curing process. This curing not only solidifies the ink but also gives it durability and a smooth finish, setting it apart from other printing methods. As businesses look for more efficient and visually striking printing solutions, understanding and adopting UV DTF technology has never been more critical.

The Benefits of UV DTF Transfers

One of the primary advantages of UV DTF transfers lies in their quality and durability. Unlike traditional printing methods, UV DTF technology ensures that the printed output is highly resistant to wear, fading, and scratches. This means products utilizing UV DTF prints maintain their vibrant appearance over time, making them ideal for high-use items like promotional materials or apparel. Businesses gain from this longevity as it reduces the need for frequent replacements, translating into significant cost savings over the long run.

Additionally, the superior quality of UV DTF transfers enables brands to stand out in a crowded market. With the ability to print intricate designs and vivid colors, businesses can offer unique products that appeal to consumers’ desire for personalization. The reliability and aesthetic quality of UV DTF prints create an enticing proposition for companies seeking to enhance their brand visibility and market competitiveness.

Versatile Applications of UV DTF Technology

UV DTF printing technology is celebrated for its remarkable versatility. Unlike conventional Direct-to-Garment (DTG) printing, which is often limited to cotton fabrics, UV DTF can be applied to an extensive selection of substrates, including plastic, glass, metal, wood, and more. This versatility not only expands the range of products that can be customized but also opens the door to creative possibilities that were previously unattainable. Businesses can explore diverse markets and cater to various customer preferences without being constrained by material limitations.

The ability to print on different surfaces allows manufacturers to create innovative designs across numerous industries—from custom clothing and retail merchandise to unique home decor items. This capability positions UV DTF technology as a powerful tool for designers and businesses aiming to differentiate themselves by offering distinctive and personalized products that resonate with their target audience.

Cost-Effectiveness of UV DTF Transfers

In an economic landscape where cost efficiency is paramount, UV DTF transfers emerge as a remarkably cost-effective printing solution. The technology allows businesses to produce shorter runs of customized products without the need for large inventory investments. By adopting UV DTF printing, companies can respond quickly to market demands, producing on-demand items that align with consumer preferences while minimizing waste. This approach not only preserves resources but also significantly boosts profitability.

The dynamic capabilities of UV DTF printing cater to businesses of all sizes, enabling both small startups and large enterprises to maintain financial viability amidst fluctuating market conditions. This adaptability fosters innovation and helps companies avoid the pitfalls of overproduction, establishing UV DTF transfers as a pivotal technology in modern printing.

Speed and Efficiency in UV DTF Printing

Speed is a crucial component in the realm of printing, and UV DTF technology excels in this regard. Compared to traditional printing techniques, UV DTF allows for quicker turnaround times, empowering businesses to meet tight deadlines without compromising quality. The rapid production capabilities provided by UV DTF ensure that print shops can cater to high-volume orders with efficiency, thereby enhancing overall productivity and customer satisfaction.

Furthermore, the streamlined workflow associated with UV DTF printing reduces the labor costs and time required for production. With advancements in automated printing processes, businesses can optimize their operations, ensuring better use of resources while achieving higher output rates. This efficiency is vital for companies in competitive markets where timely delivery can make a significant difference in customer retention and loyalty.

Recent Innovations in UV DTF Technology

The landscape of UV DTF printing is continually evolving, driven by a wave of recent innovations aimed at enhancing its capabilities. Among these advancements is the development of eco-friendly inks and curing systems that prioritize sustainability without sacrificing quality. As businesses increasingly align with environmentally conscious practices, these innovations make UV DTF transfers more appealing. By utilizing greener materials and processes, manufacturers can effectively reduce their ecological footprint, appealing to a broader audience and reinforcing their commitment to sustainability.

In addition to sustainability, the integration of automation into UV DTF production processes marks a significant milestone in enhancing efficiency. Automated platforms streamline the printing process, reducing the manual labor involved and enabling businesses to scale their operations effortlessly. As automation technologies advance, companies can anticipate increased productivity, lower operational costs, and improved profit margins, solidifying UV DTF printing’s position as a front-runner in the future of custom printing solutions.

Frequently Asked Questions

What are the benefits of UV DTF transfers in printing?

UV DTF transfers offer numerous benefits, including superior print quality and durability. The UV curing process creates vibrant colors that resist fading and wear, making them ideal for high-use items. Businesses also enjoy cost-effective printing due to reduced material waste and the ability to produce on-demand items without large inventory commitments.

How does UV printing technology enhance custom printing solutions?

UV printing technology enhances custom printing solutions by allowing for a wide range of materials to be printed on, including textiles, ceramics, and metals. This versatility enables designers to create unique products tailored to customer demands, pushing the boundaries of creativity while maintaining high-quality standards.

Are UV DTF transfers a cost-effective printing option for small businesses?

Yes, UV DTF transfers are a cost-effective printing option for small businesses. They significantly lower production costs for smaller batch printing, which allows companies to fulfill on-demand orders efficiently without the risk of overproduction and waste.

What makes UV DTF transfers a durable printing solution?

UV DTF transfers are durable due to the UV curing process that solidifies the ink onto various surfaces, resulting in prints that are resistant to wear, scratching, and fading. This durability is especially beneficial for products subjected to heavy use, ensuring a longer lifespan and better value.

In what industries are UV DTF printing applications most popular?

UV DTF printing applications are popular in various industries, including apparel, promotional products, and personalized gifts. Its ability to print on diverse substrates makes it ideal for custom clothing, branded merchandise, and creative art pieces, catering to a wide array of customer preferences.

How does the speed of UV DTF printing compare to traditional methods?

UV DTF printing is typically faster than traditional printing methods, which allows for quicker turnaround times. This speed is crucial for print shops and businesses with urgent deadlines, helping to enhance productivity and meet customer satisfaction by delivering products promptly.

| Key Features | Details |

|---|---|

| Quality and Durability | UV DTF offers vibrant colors and high durability with increased resistance to wear and fading, making prints last longer. |

| Versatile Applications | Can be applied to a wide range of materials including textiles, metal, glass, and plastic, enabling creative designs across multiple industries. |

| Cost Efficiency | Lowers production costs and allows for on-demand printing, minimizing waste and helping businesses adjust to market demands. |

| Speed and Efficiency | Facilitates faster turnarounds compared to conventional methods, enhancing overall productivity and customer satisfaction. |

| Recent Developments | Focus on eco-friendly inks and automation in production, increasing sustainability and operational efficiency. |

Summary

UV DTF Transfers are transforming the landscape of printing technology with their unique ability to deliver high-quality, durable prints across a wide variety of substrates. As businesses increasingly adapt to consumer preferences for customization and sustainability, the advantages offered by UV DTF technology—such as cost efficiency, speed, and versatile applications—position it as a leading choice in the printing industry. With ongoing innovations focused on eco-friendly practices and automation, UV DTF transfers are not just a passing trend but are establishing themselves as a fundamental component for future developments in personalized printing solutions.