In the dynamic landscape of printing, **UV DTF Transfers** have emerged as a revolutionary method that combines simplicity with superior print quality. Unlike traditional printing techniques such as screen and digital printing, UV DTF leverages advanced UV printing technology to deliver vibrant colors and intricate designs onto a variety of substrates. This innovative approach not only enhances the visual appeal but also offers durability that outperforms many conventional printing methods. For businesses and creators looking to produce high-quality materials efficiently, understanding the advantages and applications of UV DTF transfers is crucial. This article will explore how this technology compares to traditional methods, enabling you to make an informed decision for your printing needs.

In recent years, the realm of printing has seen significant advancements, with UV DTF Transfers standing at the forefront as a modern printing solution. This method, which translates to Direct-to-Film printing using ultraviolet light, presents an alternative to established practices like screen printing and offset printing. The effectiveness of UV DTF technology lies in its ability to achieve high-resolution prints on diverse materials, granting designers unprecedented flexibility. As businesses seek innovative ways to enhance their product offerings, it is essential to consider the potential of UV DTF technology compared to traditional digital printing approaches. Ultimately, understanding these alternatives will facilitate the selection of the most appropriate technique for achieving desired outcomes in print quality and application versatility.

Understanding the Benefits of UV DTF Transfers

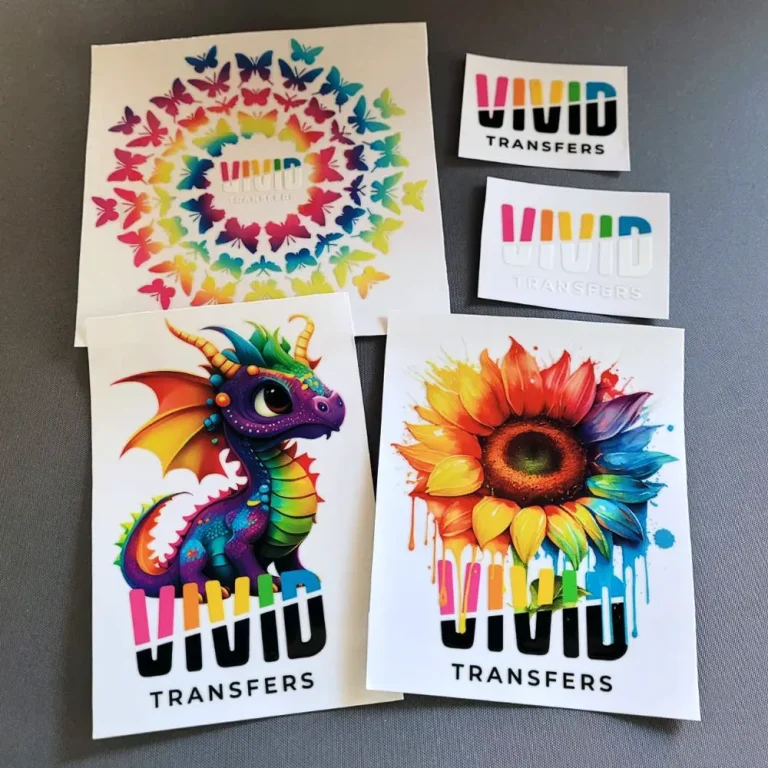

UV DTF Transfers emerge as a revolutionary solution in the printing industry, boasting significant advantages over traditional printing techniques. The primary benefit lies in the unparalleled print quality that UV DTF provides. With the ability to print on a variety of substrates—including textiles, plastics, and metals—UV DTF ensures vibrant colors and intricate details that are simply unattainable with conventional screen or offset printing methods. The UV curing process allows inks to bond seamlessly with the material, resulting in a durable and high-quality finish that withstands wear and fading.

In addition to superior print quality, UV DTF Transfers also offer remarkable customization opportunities. In a market where personalization is key, the flexibility of UV DTF technology allows businesses to produce unique, small-batch items without incurring prohibitively high costs. This capability is particularly beneficial for startups and creators looking to test their designs with diverse audiences. Unlike traditional printing, which often requires setup for large production runs, UV DTF caters to short orders efficiently, making it an attractive option for a variety of projects.

Comparing Durability: UV DTF vs. Traditional Methods

Durability is a crucial factor when it comes to choosing a printing method, and here, UV DTF Transfers hold a definitive edge. The UV curing process not only enhances the vibrancy of the colors but also creates a scratch-resistant finish—ideal for products that will face heavy usage like stickers or promotional items. Compared to traditional printing methods, such as screen printing and digital printing, UV DTF’s resilience makes it an optimal choice for items that demand longevity, providing reassurance to users that their investment will remain intact through the rigors of everyday life.

Conversely, while traditional printing methods like screen printing are known for their robustness, they often lose their advantage in terms of detail and vibrancy on complex designs. Screen printing, for example, excels in producing bold colors but can compromise on intricate artwork due to its layering process. Digital printing, while faster and less costly for small runs, can struggle with color consistency and durability against environmental factors. Thus, UV DTF Transfers emerge as a smart investment for those prioritizing both quality and longevity.

Cost Efficiency in UV DTF Transfers

When it comes to cost efficiency, UV DTF Transfers present numerous advantages that traditional printing methods struggle to match. One of the key benefits is the lower setup cost associated with UV DTF technology, making it accessible for small businesses and individuals looking to produce custom designs at a reasonable expense. In contrast, traditional printing methods may require significant upfront investments, especially in screen printing where screens need to be created for each color.

Moreover, UV DTF’s ability to produce fewer waste materials during the printing process further enhances its cost efficiency. Since changes to designs can be made easily without the need for extensive retooling, businesses can avoid the high costs associated with overproduction and leftover materials that often occur in traditional printing. This adaptability not only lowers costs but also allows for a more sustainable approach to printing—an increasingly important consideration for environmentally conscious brands.

Application Versatility of UV DTF Transfers

Application versatility is a hallmark feature of UV DTF Transfers, setting them apart from traditional printing techniques. This technology can seamlessly print on a wide variety of substrates, including hard surfaces like metals, glass, and plastics, in addition to soft fabrics. This capability allows businesses to expand their product offerings significantly, catering to diverse markets from promotional materials to fashion and home decor. Traditional printing methods, however, often fall short in this regard, typically performing best only on specific materials.

Moreover, UV DTF Transfers excel in customization, enabling intricate designs without sacrificing quality, unlike traditional methods which can struggle with detailed artworks. This characteristic makes UV DTF ideal for niches that require personalized touches, such as customized merchandise or bespoke gifts. While screen printing is excellent for bulk productions like apparel, UV DTF opens up new possibilities for small batches and individualized items, enhancing its appeal across various industries.

Recent Innovations in UV DTF Technology

The world of UV DTF technology is evolving rapidly, marked by innovations that improve the printing process’s accessibility and sustainability. Recent developments focus on enhancing the efficiency of UV printers, allowing for faster curing times and broader material compatibility. These innovations are driving down costs and making UV DTF an attractive option not only for large companies but also for small businesses that seek to capitalize on custom printing opportunities.

Additionally, advancements in eco-friendly UV ink formulations have reduced the environmental impact associated with printing. These inks are designed to emit lower levels of volatile organic compounds (VOCs), providing a cleaner alternative to traditional inks. As more businesses prioritize sustainability, the eco-conscious benefits of UV DTF technology position it favorably within the industry, aligning with modern consumers’ values and expectations.

Making the Right Choice: UV DTF vs. Traditional Printing

Choosing between UV DTF Transfers and traditional printing methods hinges on the specific requirements of a project. Business owners must carefully consider factors such as print run size, desired quality, application versatility, and budget constraints. UV DTF’s strengths in versatility and detail make it the optimal choice for unique designs and custom projects, particularly when working with diverse substrates. This flexibility allows brands to fully express their creativity without the limitations often posed by traditional methods.

On the other hand, traditional printing methods like screen printing may still hold an advantage for large-scale production runs due to lower unit costs in bulk. For established businesses with a steady demand for specific products, traditional printing might provide the economic incentives necessary for mass production. Ultimately, understanding the nuances and implications of each printing method equips businesses and creators alike to make informed decisions that align with their goals and operational needs.

Frequently Asked Questions

What makes UV DTF transfers better than traditional printing methods?

UV DTF transfers outperform traditional printing methods like screen and digital printing in print quality, delivering vibrant colors, sharp details, and durability. The UV ink curing process provides a scratch-resistant finish, making it ideal for diverse applications, especially on dark or textured materials.

How does the print quality of UV DTF transfers compare to screen printing?

While screen printing excels in color saturation and durability, UV DTF transfers achieve higher print quality with vibrant colors and intricate details, particularly on darker substrates. This makes UV DTF a preferred choice for complex designs that require precision.

Are UV DTF transfers more cost-effective than traditional printing for small runs?

Yes, UV DTF transfers typically have lower setup costs and are more economical for smaller runs or custom designs compared to traditional printing methods, which may involve higher initial costs and longer setup times.

What substrates can be used with UV DTF transfers?

UV DTF transfers offer remarkable versatility and can be applied to a wide range of substrates including plastic, metal, glass, and textiles, allowing for diverse applications that traditional printing methods might not accommodate as effectively.

What are the environmental benefits of UV DTF printing compared to traditional methods?

UV DTF technology uses UV inks that emit lower levels of volatile organic compounds (VOCs) compared to traditional inks. This results in a cleaner printing process, making UV DTF an environmentally friendly option in the printing industry.

Can UV DTF transfers provide the same durability as traditional screen printing?

Yes, UV DTF transfers can match or surpass the durability of traditional screen printing due to the UV curing process, resulting in a resistant finish suitable for items exposed to wear and tear, such as promotional materials and stickers.

| Feature | UV DTF Transfers | Traditional Printing |

|---|---|---|

| Definition | Direct-to-Film printing that uses UV light to cure ink on film substrate before transfer | Techniques like screen printing, offset printing, and digital printing that apply ink directly onto materials |

| Print Quality | Vibrant colors and exceptional detail, especially on dark or textured surfaces | Good quality but may vary; less vibrant compared to UV DTF especially on complex designs |

| Durability | Durable, scratch-resistant finish suitable for wear and tear | Durability varies; screen printing has good saturation and longevity, but may lose detail |

| Cost Efficiency | Lower setup costs and material waste, suitable for smaller runs | Economies of scale for large jobs; higher initial costs and time-consuming setup |

| Application Versatility | Can print on various substrates including plastic, metal, glass, and textiles | Best for apparel printing but restricted to specific materials |

| Recent Innovations | Advancements have improved accessibility and reduced environmental impact of inks | Innovations in inks and techniques enhance quality and compatibility |

Summary

UV DTF Transfers are revolutionizing the printing industry with their innovative approach and exceptional quality. As businesses and creators evaluate their printing needs, it becomes crucial to consider the distinct advantages of UV DTF over traditional methods. UV DTF transfers not only offer vibrant color output and superior durability, making them ideal for customized projects, but they also support a wide range of substrates. This flexibility allows for unmatched creativity in design and application, empowering users to produce high-quality prints without being limited by traditional printing methods. With lower setup costs and material efficiency, UV DTF becomes an appealing choice for startups and artists seeking uniqueness in their products. Ultimately, while traditional printing methods have their solid place for mass production, UV DTF transfers stand out for those prioritizing personalization and detail in their projects.