The DTF Gangsheet Builder is a transformative tool in the world of DTF printing, streamlining the gangsheet optimization process and enhancing print quality. With its ability to efficiently utilize designs across various fabrics, this innovative software empowers users to maximize resources while achieving stunning, vibrant prints. In our detailed guide, you’ll discover effective strategies to harness the full potential of your DTF gangsheet builder, from selecting high-quality materials to fine-tuning print settings for the DTF transfer process. Whether you’re a seasoned professional or a newcomer, understanding the capabilities of the DTF Gangsheet Builder will elevate your printing projects to new heights. Dive into the realm of DTF design software and learn how to make your printing operation both efficient and cost-effective.

The DTF Gangsheet Builder, often referred to as a direct-to-film sheet optimizer, plays a vital role in today’s garment and merchandise printing landscape. This sophisticated tool facilitates the effective arrangement of multiple designs on a single film print, simplifying the intricate DTF transfer process while ensuring detailed and high-quality output. By employing advanced design software, users can enhance their workflow, making the most of their resources and ultimately delivering vibrant designs effortlessly. Furthermore, this printing method has grown in popularity for its versatility, allowing printed images to be transferred onto a variety of textiles. Exploring this innovative approach offers insights into utilizing gang sheets effectively for optimal print outcomes.

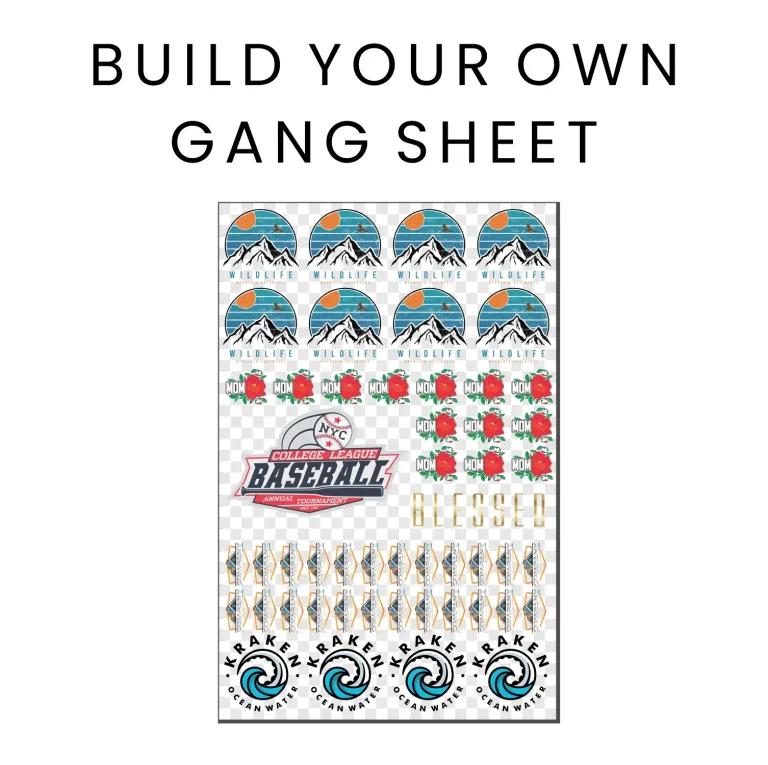

Maximizing Efficiency with DTF Gangsheet Builder

To truly maximize efficiency with your DTF gangsheet builder, it’s important to understand the workflow from start to finish. Begin by ensuring that your artwork is optimized for DTF printing; this includes adjusting the resolutions and color modes to achieve the best results. Utilizing vector graphics or high-resolution images helps maintain clarity and vibrancy during the transfer process. The organization of your gangsheet design is just as critical, as proper alignment and grouping can reduce material waste and streamline the production phase.

Implementing a systematic approach to your DTF gangsheet builder means not only focusing on the design aspect but also considering the printing environment. Keeping your workspace organized, maintaining printer cleanliness, and regularly checking the calibration can significantly decrease printing errors. Additionally, consider the sequence of your designs on the gangsheet, ensuring that similar materials and colors are grouped together to minimize the chances of printer adjustments mid-print.

Essential Materials for Quality DTF Outputs

The choice of materials plays a crucial role in the quality of your DTF prints. Begin with selecting high-grade transfer films and adhesives that are specifically designed for DTF printing; this ensures maximum adhesion and durability of the prints. Brands like Trekk or U.S. Specialty Coatings offer products that are not only compatible but also enhance the overall print quality, providing vibrant colors that stand the test of time. Furthermore, using a high-quality printer and specialized inks that are optimized for DTF will enhance the saturation and vibrancy of your prints.

In conjunction with quality films and adhesives, consideration for the fabric type is also paramount. Different materials may require particular settings or adaptations in the transfer process; for instance, cotton and polyester may respond differently to heat and pressure during the application. Understanding these nuances and selecting the right materials according to the product can make a significant difference in the final output, ensuring that designs not only look stunning but also remain intact even after multiple washes.

Leveraging DTF Design Software

Utilizing DTF design software effectively can streamline your printing process. Most dedicated DTF gangsheet builders come with their proprietary software that aids users in crafting designs specifically tailored for DTF printing. By learning the functionalities within these programs, such as template use and pre-set color profiles, you can achieve greater consistency in your prints. Implementing templated designs that are pre-optimized for size and layout will not only save time but ensure that each design is well-suited to the gangsheet dimensions.

Additionally, color management within the software is a vital aspect of achieving true-to-life prints. Most DTF design software offers pre-configured color profiles that can significantly reduce discrepancies between screen and print colors. Educating yourself on these tools will allow you to fine-tune your designs further, ensuring your prints are not only vibrant but also reflective of your original creations. Such attentiveness to detail within your software can lead to professional-grade outputs, setting your work apart in a competitive market.

Optimizing Print Layouts for Cost Efficiency

The layout of your gangsheet can heavily influence both cost efficiency and output quality. By strategically placing multiple designs on a single sheet, you can drastically reduce waste and maximize the use of materials. This involves not only thoughtful arrangement but also utilizing software features that assist in aligning designs accurately. The benefits of a well-planned layout extend beyond material savings; they can also simplify the transfer process, reducing the time and resources spent on printing tasks.

An effective strategy for optimizing your print layouts is to take advantage of features such as grid lines or alignment tools that many DTF design software programs offer. These tools help ensure that each design is positioned correctly on the gangsheet, minimizing the risk of overlapping or misalignment during the transfer process. Assessing and adjusting your layouts before printing can lead to significant reductions in wasted materials and time, ultimately enhancing your productivity and profitability.

Fine-Tuning Print Settings for Superior Quality

Getting the most out of your DTF gangsheet builder also hinges on the calibration of your printer settings. Every printer is slightly different, and experimenting with various settings such as ink distribution, temperature, and speed can lead to improved print quality. Regular maintenance of your DTF printer not only enhances performance but helps in catching potential issues before they escalate, ensuring that each print meets the highest standards of quality.

Conducting test prints is an invaluable practice that allows you to monitor how your adjustments impact the final output. By analyzing different configurations, such as varying the print resolution or experimenting with speed settings, you can pinpoint the ideal setup for your specific materials and designs. Engaging with online communities can also provide insights into successful settings from other users, allowing you to further refine your approach and enhance your DTF printing outcomes.

Engaging with the DTF Community for Insights

The DTF printing community offers a treasure trove of collective knowledge that can be incredibly beneficial when maximizing your gangsheet builder. By joining online forums or social media groups, you’ll gain access to a diverse array of tips, tricks, and techniques that other users have discovered through trial and error. Connecting with fellow DTF enthusiasts not only provides immediate solutions for common challenges but also introduces you to innovative strategies that may not be covered in formal resources.

Additionally, engaging actively with the community can offer fresh perspectives on the latest trends and advancements in DTF technology. Stay informed about industry developments by participating in discussions about new materials, software updates, and machinery reviews. This continuous learning environment can empower you to implement the best practices and cutting-edge solutions, thereby enhancing your printing efficiency and output quality. Following experienced users can guide you towards avoiding common pitfalls, further enriching your DTF printing journey.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it enhance DTF printing?

A DTF Gangsheet Builder is a specialized tool used in Direct to Film (DTF) printing that allows users to optimize the layout of multiple designs on a single film sheet. This optimization reduces material waste and improves print efficiency, enabling vibrant prints across various fabrics.

How can I optimize my designs when using a DTF Gangsheet Builder?

To optimize designs with a DTF Gangsheet Builder, use pre-designed templates that align with gangsheet dimensions. Group multiple designs together to maximize space and ensure proper alignment. This method conserves materials while enhancing print quality during the DTF transfer process.

What materials should I choose for the best performance with a DTF Gangsheet Builder?

Selecting high-quality transfer films and adhesives, such as those from Trekk or U.S. Specialty Coatings, is essential for maximizing your DTF Gangsheet Builder’s performance. Quality materials significantly impact print quality and durability of the final product.

How does the print setting affect the output quality in DTF printing with a gangsheet?

Calibrating the print settings according to the materials and inks used is crucial for achieving high-quality outputs in DTF printing. Regular maintenance of your DTF printer ensures optimal print quality, while test prints can help in fine-tuning adjustments before larger runs.

What are the advantages of using software tools with a DTF Gangsheet Builder?

Utilizing proprietary software with your DTF Gangsheet Builder simplifies the printing process by offering alignment tools, color profile presets, and design templates. These features enhance efficiency, maintain color consistency, and streamline the overall workflow in DTF printing.

How can community engagement benefit my use of DTF Gangsheet Builder?

Engaging with the DTF printing community through online forums and social media can provide valuable insights and troubleshooting tips. Sharing experiences and learning from others expands your knowledge base and introduces innovative techniques for effectively utilizing your DTF Gangsheet Builder.

| Key Point | Description |

|---|---|

| Understanding DTF Technology | DTF printing transfers designs onto fabric using heat and adhesives, offering vibrant and detailed prints. |

| Choosing the Right Materials | Use high-quality transfer films and adhesives, such as Trekk and U.S. Specialty Coatings, to enhance print quality. |

| Software Utilization | Familiarize yourself with the proprietary software of your DTF gangsheet builder to streamline the workflow. |

| Print Size and Layout | Efficient layout planning can save material and labor by grouping designs efficiently. |

| Adjusting Print Settings | Regularly calibrate your printer settings and carry out maintenance to ensure high-quality outputs. |

| Learning from the Community | Engage with online forums to share insights and learn from other users’ experiences. |

| Current Trends and Innovations | Stay updated on new technologies and trends to enhance your DTF printing capabilities. |

Summary

DTF Gangsheet Builder is crucial for maximizing the efficiency of your DTF printing process. By understanding the technology behind DTF printing and taking into account factors like material quality, software efficiency, and community insights, users can significantly enhance their print quality and productivity. Selecting the right materials, utilizing software tools effectively, optimizing print sizes and layouts, and staying updated on industry trends will collectively ensure that you not only achieve beautiful prints but also maintain cost-effectiveness and reduce waste in your operations. Embracing these strategies is essential for anyone looking to excel with their DTF Gangsheet Builder, making it an invaluable asset for both amateur and professional printers.