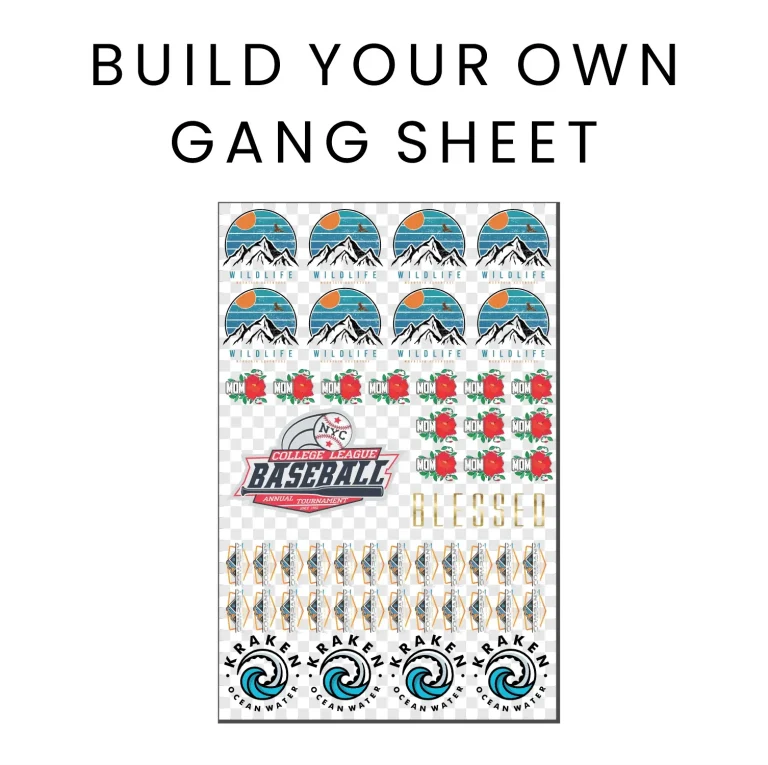

The DTF Gangsheet Builder is a game-changing tool in the realm of Direct-to-Film (DTF) printing, transforming the way designs are handled on a single sheet. By utilizing the DTF Gangsheet Builder, you can maximize your print output against the backdrop of the burgeoning DTF printing process, allowing for vibrant, durable designs on various textiles. In this blog post, we will delve into how to use the DTF Gangsheet effectively, exploring various DTF printing techniques that ensure accuracy and quality. Efficient gangsheet printing not only saves time but also minimizes material waste, making it an essential aspect of modern textile printing operations. As we guide you through the steps of creating your own gangsheet, we will introduce you to proven DTF design software that makes the process seamless and user-friendly.

When it comes to DTF printing, the use of a specialized gangsheet organizer plays a pivotal role in optimizing your print runs. This innovative gangsheet builder allows for the strategic arrangement of multiple graphics on a single transfer film, enhancing efficiency in the printing workflow. By mastering this tool, you’ll learn how to navigate the intricacies of the DTF printing techniques that promise rich colors and a smooth finish. The ability to combine various designs into one print not only reduces production costs but also streamlines the entire process, catering to both novice and seasoned printers alike. Explore how to harness the power of DTF design software to elevate your printing projects beyond traditional methods.

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process is changing the way textiles are printed today. In essence, DTF printing allows for high-quality, detailed designs to be printed on a specially coated film before they are transferred onto fabric. This method is incredibly versatile, supporting a variety of materials including cotton, polyester, and blends, which opens up a plethora of creative opportunities for designers.

Central to this method is the use of modern printing technology that ensures vibrant colors and fine details are preserved. DTF printing utilizes water-based inks that not only yield exciting visuals but also provide excellent durability once cured. As a result, garments maintain their quality wash after wash, making DTF a preferred choice in fashion retail and custom apparel.

Efficient Use of the DTF Gangsheet Builder

Utilizing the DTF Gangsheet Builder optimally significantly streamlines the printing workflow. This tool allows users to compile multiple designs onto one sheet, which boosts productivity by minimizing waste. By consolidating designs, it helps reduce the material costs associated with smaller prints, thereby increasing profit margins.

Moreover, the DTF Gangsheet Builder allows for clever spatial organization of various designs, ensuring an efficient layout that maximizes the use of the available print area. This intelligent arrangement capabilities mean that users can get more prints out in less time, facilitating batch processing and allowing for quicker turnaround on orders.

How to Use the DTF Gangsheet Builder Effectively

To effectively use the DTF Gangsheet Builder, it’s crucial to start with high-resolution graphics. Choosing the right designs that complement each other visually not only provides a cohesive look but also enhances the efficiency of the print run. After selecting your designs, preparing your software becomes your next significant step.

Once in your design software, such as Adobe Illustrator or specialized DTF design software, you can arrange your graphics on the gangsheet optimally. Many programs allow for predefined templates which can speed up this process and ensure that you take full advantage of the printable area, avoiding empty spaces that lead to wasted materials.

Essential Tools for DTF Printing Success

When diving into DTF printing, having the right tools can make all the difference. Apart from the DTF Gangsheet Builder, investing in quality DTF design software significantly enhances your design capabilities. Software with features tailored for DTF printing simplifies the creation of layouts, making it easier to arrange designs for gangsheet printing.

Additionally, a reliable DTF printer that supports the required ink technology is vital for ensuring the prints come out as expected. These printers typically have settings that enable accurate color profiles which are crucial for delivering vibrant and true-to-design outputs.

Best Practices for DTF Printing Techniques

Employing best practices in DTF printing techniques enhances print quality and operational efficiency. One simple yet effective practice is to maintain a clean and clutter-free printing environment. Dust particles can easily affect print quality, so regular cleaning of the printer is essential for consistent results and longer equipment lifespan.

Another best practice is to regularly consult updated resources and tutorials on DTF printing techniques. Websites and video tutorials can offer insight into advanced methods and troubleshooting tips, enabling users to optimize their processes continually and keep pace with industry developments.

Future Trends in DTF Printing and Gangsheet Applications

As the demand for customized apparel continues to rise, the future of DTF printing looks very promising. Increased advancements in technology will lead to improved printing speeds and enhanced color capabilities, allowing DTF printers to cater to larger production runs without sacrificing quality.

In addition, the use of eco-friendly DTF printing materials is likely to grow, driven by consumer demand for sustainable fashion solutions. Innovations in environmentally friendly inks and films will not only benefit the planet but also appeal to a more conscious consumer base, aligning printing businesses with modern ethical standards.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it benefit DTF printing?

The DTF Gangsheet Builder is a specialized tool that compiles multiple designs onto a single film sheet, optimizing the DTF printing process. By using this builder, users can maximize print output, reduce material waste, and streamline workflows, leading to cost-effective and efficient printing.

How do I use the DTF Gangsheet Builder for my printing projects?

To use the DTF Gangsheet Builder, start by selecting high-resolution designs and preparing your design software. Arrange your designs on a new document that matches the DTF film dimensions, resize them as needed, and then check your printer settings before printing the gangsheet.

What software is best for creating designs with the DTF Gangsheet Builder?

For optimal results with the DTF Gangsheet Builder, consider using software such as Adobe Illustrator, CorelDRAW, or specialized DTF design software. These tools provide the features needed for effective design creation tailored to the DTF printing process.

Are there specific printer settings I should configure when using the DTF Gangsheet Builder?

Yes, when using the DTF Gangsheet Builder, ensure that the printer settings are adjusted to the correct DPI for quality output and that the appropriate color profiles are selected to accurately reflect your designs during printing.

What are some tips for maximizing efficiency when using the DTF Gangsheet Builder?

To maximize efficiency with the DTF Gangsheet Builder, consider batch processing similar designs, using templates for quick setup, and maintaining your printer regularly to prevent issues that could affect print quality.

How do I apply adhesive powder after printing with the DTF Gangsheet Builder?

After printing the gangsheet using the DTF Gangsheet Builder, evenly sprinkle hot-melt adhesive powder over the wet ink. This step is crucial as the adhesive allows the ink to bond with fabric during the subsequent heat transfer process.

| Key Point | Details |

|---|---|

| Introduction | DTF printing aids in creating vibrant and durable prints, with DTF Gangsheet Builder optimizing print output. |

| What is DTF Gangsheet Builder? | A tool that compiles multiple designs on a single sheet, enhancing efficiency and reducing waste. |

| Basic Understanding of DTF Printing | Involves printing on a special film for heat transfer to various fabrics. |

| Step 1: Select Designs | Choose high-resolution graphics suitable for DTF printing. |

| Step 2: Prepare Software | Use software like Adobe Illustrator or specialized DTF tools to create designs. |

| Step 3: Arrange Designs | Import graphics into design software and arrange them in the document. |

| Step 4: Resize Images | Adjust designs to fit the gangsheet, optimizing space effectively. |

| Step 5: Check Printer Settings | Confirm DPI and color profiles before printing. |

| Step 6: Print Gangsheet | Send to DTF printer and monitor the process for alignment. |

| Step 7: Apply Adhesive Powder | Sprinkle hot-melt adhesive over the printed designs while wet. |

| Step 8: Cure the Print | Use a heat press to set the adhesive and bond prints to fabric. |

| Step 9: Final Application | Peel off transfer film; designs should be securely bonded. |

| Efficiency Tips | Batch similar designs, use templates, and maintain your printer regularly. |

Summary

DTF Gangsheet Builder is a vital aspect of mastering DTF printing, as it not only enhances efficiency but also significantly reduces material waste. By efficiently compiling various designs onto a single sheet, users can ensure high-quality outputs while streamlining their workflow. Whether you’re new to DTF printing or looking to refine your skills, using the DTF Gangsheet Builder offers numerous advantages that contribute to a successful printing operation. Practicing the techniques outlined in this guide will help you become proficient in the DTF process, ultimately leading to improved results and profitability.