In the rapidly evolving world of printing technology, **UV DTF transfers** are emerging as a game-changing innovation that is redefining the landscape of customization in printing. This groundbreaking approach utilizes UV printing technology to create vibrant, high-quality designs that can be transferred onto a variety of materials with exceptional precision. As businesses increasingly seek personalized printing solutions, UV DTF transfers stand out for their efficiency and sustainability, appealing to eco-conscious consumers and operators alike. With a focus on automated UV printing processes, companies are now able to produce intricate, tailor-made designs that perfectly align with unique customer preferences, demonstrating the future of customization. As we explore the significance of this transformative technology, we uncover a myriad of trends that indicate a surge in demand for more distinct and individualized products.

Revolutionizing the realm of custom printing, **UV Transfer to Film** technology has quickly garnered attention for its innovative approach to delivering personalized results. In a landscape where tailored designs are vital, this cutting-edge technique leverages advancements in ultraviolet ink technology to enhance print quality and durability across different substrates. With a growing shift towards individualized consumer experiences, businesses are embracing methods that incorporate sustainable printing practices, thus ensuring a minimal environmental impact. Automated systems in UV Transfer to Film processes further increase efficiency, reducing production costs while meeting high demand for custom graphics. This paradigm shift not only provides aesthetic benefits but also positions enterprises at the forefront of the customization trend within the printing industry.

Understanding UV DTF Transfers: A Breakthrough in Customization

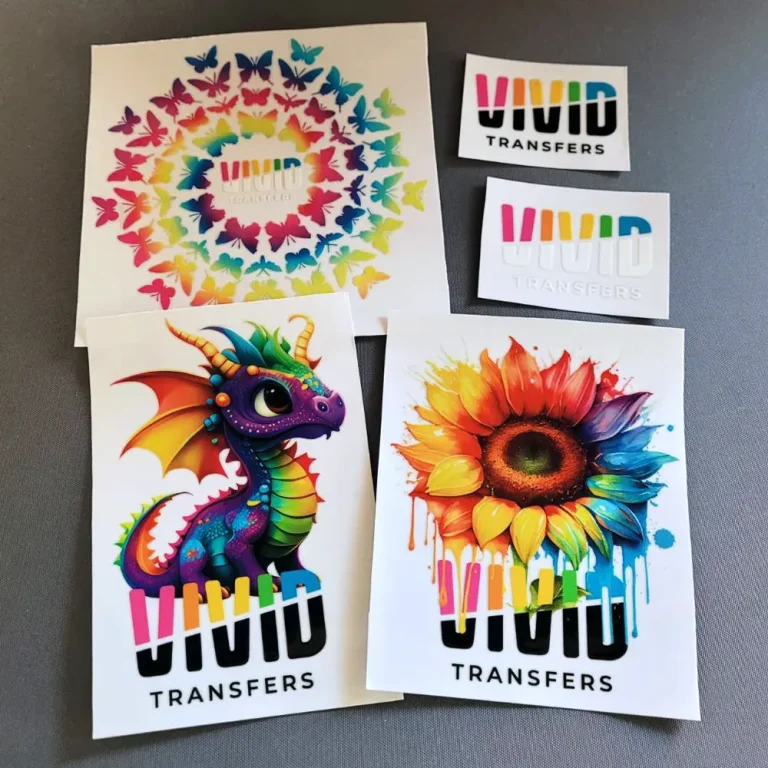

UV Direct to Film (DTF) transfers represent a cutting-edge advancement in the printing industry, catering to the fast-evolving demand for personalization in consumer products. The UV DTF process utilizes ultraviolet light to cure ink printed onto a film, allowing for high-quality prints that can adhere to a variety of substrates. This technology is not only robust in its output but also versatile, making it suitable for textiles, hard surfaces, and promotional materials. As businesses strive to meet the growing consumer appetite for customization in printing, UV DTF transfers stand out for their ability to deliver intricate designs, vibrant colors, and durable finishes.

The process of UV DTF printing involves several steps: printing on a special transfer film, curing the ink with UV light, and then applying the design to the desired surface with heat and pressure. This method aptly aligns with the modern consumer’s desire for unique and bespoke products. By utilizing automated UV printing technology, companies can significantly reduce production time and enhance their output consistency. This combination of efficiency and quality makes UV DTF transactions an attractive option for businesses looking to enter new markets and expand their personalization capabilities.

The Rising Importance of Sustainable Practices in UV DTF Printing

As environmental concerns become increasingly pivotal in consumer decision-making, the UV DTF printing industry is responding by adopting sustainable printing practices. Traditional printing methods often generate substantial waste and utilize harmful inks, but UV DTF technology is revolutionizing this paradigm. The use of eco-friendly inks that are cured with UV light minimizes resource consumption and reduces harmful emissions, appealing to environmentally conscious customers. Furthermore, the efficiency of the UV DTF process contributes to lower energy consumption, allowing printing companies to uphold sustainable values while enhancing their market appeal.

The commitment to sustainability fosters a stronger connection between brands and consumers who prioritize ecological responsibility. Printing businesses that invest in sustainable practices within UV DTF technology not only bridge the gap between quality and eco-friendliness but also position themselves as industry leaders. By implementing these practices, companies can also differentiate themselves in a crowded marketplace, as consumers increasingly seek brands that align with their values. Hence, the focus on sustainable printing not only benefits the environment but also serves as a vital marketing strategy.

Incorporating eco-friendly methods into production not only reflects a company’s values but also opens doors to a growing number of market segments looking for responsible choices. As businesses embrace automation in UV printing, they can scale their sustainable practices further, reaping both ecological benefits and improved operational efficiency.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers use UV printing technology to print designs on a special film, which is then cured with ultraviolet light to create vibrant, durable prints. This method allows for customization in printing, enabling intricate designs and personalized printing solutions across various surfaces.

How does UV DTF technology contribute to sustainable printing practices?

UV DTF technology supports sustainable printing practices by employing eco-friendly inks and producing less waste compared to traditional methods like screen printing. This not only minimizes environmental impact but also aligns with the growing consumer demand for sustainability in product offerings.

Why is personalization important in UV DTF transfers?

Personalization is crucial in UV DTF transfers because it meets the increasing consumer demand for unique and customized products. This printing method allows businesses to create tailored designs that resonate with individual preferences, thus enhancing brand loyalty and customer satisfaction.

What advancements are being made in UV DTF printing technology?

Recent advancements in UV DTF printing technology include improved ink formulations for better adhesion and durability, faster curing processes, and enhanced color vibrancy. These innovations enable businesses to produce high-quality prints more efficiently, addressing the competitive demands of today’s market.

Can UV DTF transfers be automated, and what are the benefits?

Yes, UV DTF transfers can be automated, which offers significant benefits such as increased production consistency, reduced labor costs, and minimized errors. The integration of automated printing systems allows businesses, particularly SMEs, to optimize their resources and enhance operational efficiency.

What industries are adopting UV DTF transfers for their customization needs?

Various industries are adopting UV DTF transfers, especially those in sportswear, fashion, and promotional products. This technology enables companies to provide distinctive and customizable designs, appealing to markets that prioritize individuality and unique branding strategies.

| Key Trend | Description |

|---|---|

| Market Growth | Projected growth of UV DTF technology with increased demand for customization and personalization in products. |

| Technological Advancements | Improvements in ink formulations, faster curing processes, and enhanced print quality meet high-demand scenarios. |

| Sustainability Focus | Adoption of eco-friendly inks and processes, producing less waste compared to traditional printing methods. |

| Personalization Demand | Increasing preference for customized products with unique designs appealing to various markets. |

| Integration of Automation | Use of automated systems to enhance consistency, reduce errors, and lower operational costs. |

| Application Expansion | Growing use of UV DTF transfers in diverse sectors like sportswear and luxury fashion for unique designs. |

Summary

UV DTF Transfers represent a significant advancement in the field of printing, driven by technological innovations and an increasing demand for personalized products. With the projected growth of the UV printing market and the emphasis on sustainability, businesses adopting UV DTF technologies can expect to thrive. The industry’s focus on customization caters to a wide range of consumer preferences, while automation enhances productivity and efficiency. As UV DTF technology expands into new markets, it will play a crucial role in shaping the future of personalized printing solutions.