In today’s rapidly evolving printing landscape, UV DTF transfers stand out as a revolutionary technique that combines the brilliance of UV printing technology with the efficiency of direct to film printing. This cutting-edge method enables custom prints that are not only vibrant but also extraordinarily durable, opening up numerous applications across various industries. With an increasing demand for sustainable printing solutions, UV DTF offers an eco-friendly alternative by minimizing harmful emissions associated with traditional printing processes. This introduction to the advantages, innovations, and market trends surrounding UV DTF applications will provide you with an insightful perspective on its impact on the future of print media. Join us as we delve deeper into unlocking the immense potential of UV DTF transfers for your business needs.

Exploring the world of UV DTF transfers reveals a dynamic intersection of technology and creativity, often referred to as direct transfer film printing or UV curing techniques. As businesses strive for efficiency and quality in their printed products, alternative terminology such as UV film applications and sustainable printing methods become increasingly relevant. These innovative printing solutions cater to a wide range of materials and are designed to meet the customized demands of today’s market. With a focus on delivering vibrant, long-lasting prints, the importance of environmentally conscious practices is also highlighted within this field. Discover how these advancements are shaping the future of custom printing and expanding creative possibilities across various sectors.

Understanding UV DTF Transfers in Depth

UV DTF transfers, or Direct to Film transfers, are revolutionizing the printing industry by offering a hybrid approach that merges traditional DTF techniques with advanced UV printing technology. This method leverages the unique properties of UV-curable inks that dry instantly upon exposure to ultraviolet light, allowing for exceptionally vibrant and long-lasting prints. The significance of this technology lies in its versatility to cater to various substrates, even those that were previously difficult to print on effectively. Through this innovation, businesses are now empowered to create visually striking designs on a myriad of materials, enhancing the aesthetic appeal of products across multiple sectors.

The equipment and process involved in UV DTF printing have also seen major enhancements. With the continuous evolution of printers capable of higher resolutions and improved speed, companies can now deliver more intricate designs at a faster pace. This capability is particularly beneficial in the fashion and promotional products sectors, where customer demands for customization and quick turnaround times are consistently on the rise. As industries adopt UV DTF transfers, they are combining quality and efficiency, positioning themselves competitively in the marketplace.

Key Advantages of Using UV DTF Technology

One of the standout benefits of UV DTF transfers is their supreme durability. Unlike conventional ink systems that may fade or deteriorate under environmental stressors, UV-cured inks are inherently resilient. Their strong adhesion to various surfaces ensures that prints maintain their vivid colors and structural integrity even when exposed to sun, moisture, and abrasives. This durability makes UV DTF an ideal choice, particularly for outdoor signage and apparel that is subjected to frequent wear and tear.

In addition to durability, UV DTF technology excels in offering vibrant colors that retain their brilliance over extended periods. Businesses utilizing this method can expect their prints to resound with quality, helping to enhance branding and visibility. Furthermore, the customizability afforded by UV DTF allows for a variety of finishes, enabling brands to experiment with textures and visual effects that set them apart from competitors.

Exploring the Versatile Applications for UV DTF Transfers

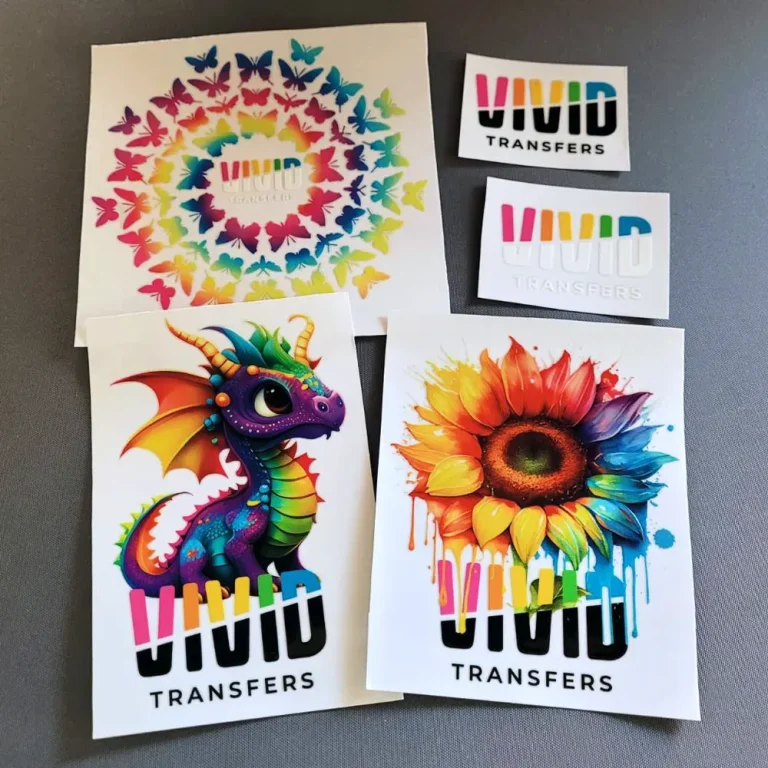

The versatility of UV DTF technology extends to a broad range of applications, which positions it as a favored choice for many industries. Fashion labels use UV DTF to produce custom pieces that showcase unique designs and logos. These prints not only serve as promotional tools but also add a flair of artistry to clothing items, attracting a diverse customer base eager for personalized fashion. Additionally, companies looking to enhance merchandise sales find UV DTF ideal for creating customized accessories and branded promotional items that stand out.

Beyond the realm of fashion, UV DTF has proven to be effective in signage and advertising. Businesses can quickly produce high-quality, colorful signs that remain clear and impressive even in bright lighting or harsh weather conditions. The quick curing time associated with UV inks accelerates production, enabling timely delivery of projects—an essential factor in fast-paced business environments. From indoor displays to outdoor advertising, of custom prints keep brands relevant and engaging in their marketing efforts.

Sustainability: The Eco-Friendly Edge of UV DTF Printing

Sustainability is more than a trend in the printing industry; it is a necessity. UV DTF transfers align with this ethos by utilizing inks that emit lower levels of volatile organic compounds (VOCs) compared to traditional printing methods. This not only reduces harmful emissions during production but also makes UV DTF a safer choice for workers and consumers alike. Brands are increasingly aware of their environmental impact, making the eco-friendliness of UV DTF an attractive selling point in their marketing strategies.

Moreover, the long-lasting nature of UV DTF prints diminishes the need for frequent replacements, further promoting sustainability. Less waste means less material is consumed over time, and businesses can confidently market their products as environmentally responsible choices. As consumers become more eco-conscious, adopting UV DTF technology gives companies a competitive edge in a marketplace that prioritizes sustainable practices.

Materials and Surface Compatibility in UV DTF Printing

One of the remarkable features of UV DTF technology is its ability to adhere to a diverse array of materials. Recent innovations have introduced specialized inks that expand compatibility with surfaces, including fabrics, metals, glass, and various plastics. This versatility empowers businesses to explore creative applications for their products, enhancing innovation across a range of industries. The technological advancements in adhesion properties mean that companies can push the boundaries of product design, adding aesthetic value without compromising on quality.

Furthermore, this compatibility ensures that businesses can cater to bespoke requirements from their clients effectively. Whether it’s creating custom designs for promotional events or producing intricate artwork on various types of merchandise, UV DTF provides the adaptability needed to meet ever-changing consumer tastes and market demands. As the industry continues to advance, we can expect even greater possibilities in the materials that can be printed upon, broadening the scope for creative and unique branding solutions.

Future Trends in UV DTF Technology

The future of UV DTF technology appears bright as ongoing innovations reshape the printing landscape. As competition in the market grows, manufacturers are investing in developing higher-resolution printers capable of producing ultra-fine details, which enhances the quality of custom prints. This drive towards better technology supports the increasing demand for personalization in products, allowing businesses to meet varied customer preferences with ease.

In addition, as businesses become more environmentally conscious, advancements in UV DTF are likely to focus on creating even more sustainable solutions. Manufacturers are exploring ways to optimize ink formulations and printing processes that further minimize environmental impact while still delivering high-performance results. As these trends continue to gain traction, UV DTF transfers will likely solidify their position as leading solutions among printing technologies, ensuring that businesses can meet both quality and sustainability goals.

Frequently Asked Questions

What are UV DTF Transfers and how do they work?

UV DTF Transfers combine UV printing technology with direct to film (DTF) printing to produce high-quality prints on flexible films. This method uses ultraviolet light to cure inks during the printing process, resulting in vibrant, durable images that can adhere to a variety of substrates.

What are the benefits of using UV DTF printing technology?

The main benefits of UV DTF printing technology include exceptional durability, vibrant color retention, and the ability to create custom prints tailored to specific applications. These advantages make UV DTF transfers ideal for both indoor and outdoor uses across diverse industries.

In what industries is UV DTF technology applied?

UV DTF technology is rapidly gaining traction in several industries, including apparel for custom clothing, promotional items for branded merchandise, and signage for creating lasting outdoor displays. Its versatility allows businesses to leverage this technology for various marketing needs.

How do UV DTF Transfers contribute to sustainable printing solutions?

UV DTF Transfers are considered sustainable printing solutions because they emit significantly fewer volatile organic compounds (VOCs) compared to traditional printing methods. This eco-friendly approach aligns with the industry’s commitment to reducing environmental impacts while providing high-quality prints.

What materials can UV DTF Transfers be printed on?

Recent advancements in UV DTF technology allow for printing on a diverse range of materials, including fabrics, metals, plastics, wood, and glass. This compatibility broadens the applications of UV DTF transfers, enabling innovative designs on varying surfaces.

What finishing techniques enhance the quality of UV DTF prints?

To maximize the quality and longevity of UV DTF prints, techniques such as heat treatment and lamination are recommended. These post-processing methods enhance durability, protect the prints from scratching, and ensure they maintain vibrancy over time.

| Key Point | Description |

|---|---|

| Introduction | UV DTF transfers combine traditional DTF printing and UV technology, enhancing application versatility. |

| UV DTF Technology | Utilizes UV light to cure inks for vibrant, durable images on flexible films. |

| Benefits | Durability, color vibrancy, and customizability are key advantages. |

| Applications | Widely used in apparel, promotional items, and signage. |

| Environmental Considerations | UV DTF inks emit fewer VOCs, making them a sustainable choice. |

| Materials Compatibility | Adhesion to various surfaces, including fabric, metals, and plastics. |

| Market Trends | Growth predicted due to innovation in printing technology and faster production. |

| Post-Processing Techniques | Heat treatment and lamination recommended to enhance print longevity. |

Summary

UV DTF transfers are revolutionizing the printing landscape by offering exceptional durability and a diverse range of applications across multiple industries. These innovative transfers leverage UV technology to produce vibrant, long-lasting prints that are environmentally friendly and suitable for various substrates. As businesses increasingly seek sustainable and customizable solutions, UV DTF transfers provide a promising avenue for enhancing product quality and expanding creative possibilities. With continued advancements shaping the future of UV DTF technology, now is the perfect time for companies to explore its potential and maximize their printing capabilities.