In the dynamic realm of custom printing, UV DTF transfers have emerged as an innovative solution that is reshaping the industry landscape. By harnessing advanced UV ink technology, these transfers deliver high-quality printing with vibrant colors and intricate designs on a variety of versatile materials. As sustainability becomes increasingly important, UV DTF offers a more eco-friendly approach by reducing waste and enhancing durability, making it an ideal choice for businesses looking to create lasting impressions. Whether you’re interested in promotional products or custom apparel, UV DTF transfers are proving to be a game-changer, combining creativity with efficiency. Join us as we explore the remarkable capabilities and advantages of this cutting-edge printing technique.

Often referred to as ultraviolet direct-to-film printing, this innovative method of custom prints caters to the rising demands for high-quality visuals on diverse substrates. With its ability to produce vivid and durable prints, this technique stands out in a marketplace saturated with traditional printing options. Additionally, its sustainable printing practices align well with modern environmental considerations, making it a favorite among eco-conscious businesses. The versatility of ultraviolet DTF transfers not only expands product offerings but also enhances efficiency in production and design. Explore how this advanced printing technology can elevate your business and redefine custom product creation.

What Makes UV DTF Transfers Stand Out?

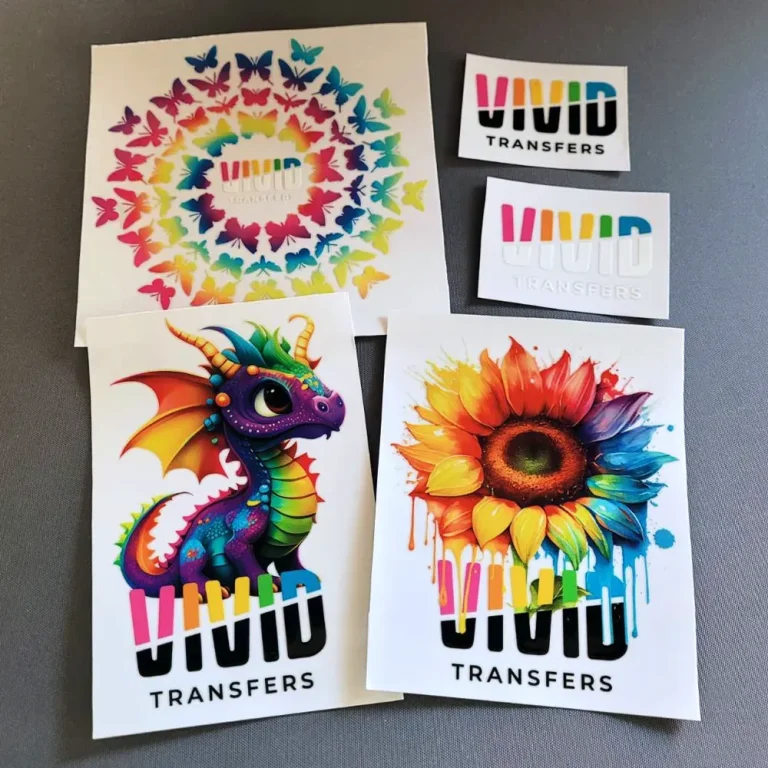

UV DTF transfers are a game-changing technology in the realm of custom printing. They stand out primarily due to their exceptional print quality and adherence to various materials. By employing ultraviolet ink, this method achieves stunning vibrancy and precision that traditional methods struggle to provide. The right use of UV DTF results in each design feature being highlighted efficiently, making it particularly beneficial for branding purposes. Companies that prioritize image representation gain a substantial edge in appealing to their target audiences thanks to the impressive results achieved with these transfers.

Moreover, the versatility inherent in UV DTF transfers is a notable advantage. This technology can be applied to an array of substrates, including hard surfaces like glass and wood, alongside fabrics and plastics. This level of material compatibility gives businesses the freedom to explore unique products that fit their brand identity, from custom clothing to promotional items. This broad application range fosters creativity and innovation in product design, setting UV DTF apart as an important player in the custom printing landscape.

Benefits of High-Quality Printing with UV DTF

High-quality printing is non-negotiable in today’s competitive market, and UV DTF transfers ensure that clients receive prints with outstanding sharpness and detail. The incredible resolution allowed by this technology is crucial for low-resolution images and graphics, transforming them into vivid representations without losing definition. Brands looking to make a lasting impression cannot overlook this feature, as the quality of visual materials directly correlates with customer engagement and retention.

Additionally, the durability of UV DTF prints means that businesses can rely on the longevity of their products. Unlike conventional printing methods, UV DTF utilizes a curing process that enhances the prints’ resistance against scratching, fading, and harsh environmental conditions. This quality not only protects customers’ investments but also enhances the perception of a brand’s reliability. As businesses emphasize quality and durability in their offerings, UV DTF technology emerges as a pivotal choice that meets these growing expectations.

Exploring Material Versatility in UV DTF Transfers

One of the standout features of UV DTF transfers is their remarkable material versatility. This method allows designers to print on a wide variety of substrates, expanding the possibilities of product creation significantly. From fabrics to metals, wood, and even certain plastics, this technology supports a diverse range of products, enabling businesses to branch out and cater to different markets and preferences.

By utilizing UV DTF transfers, brands can break away from the constraints of traditional printing, which often limits types of materials that can successfully accept prints. The freedom to customize multiple mediums opens new avenues for creative marketing approaches, allowing for unique merchandise that resonates with consumers. This versatility not only enhances a company’s product offering but also grants a competitive edge in an increasingly crowded marketplace.

The Durability Advantage of UV DTF Printing

Durability is a significant factor in custom printing, and UV DTF transfers deliver outstanding results in this regard. The UV curing process enhances the printed surface’s resistance to everyday wear and tear. Products made with this method are less likely to exhibit signs of fading or damage, ensuring they maintain an attractive appearance longer. This is particularly important for items that endure frequent use or exposure to various elements.

Furthermore, the advanced formulation of UV inks contributes to the long-lasting quality of prints. These inks create a robust layer that can withstand environmental challenges, which is a major advantage for outdoor promotional materials or apparel. In an age where consumers prioritize sustainability and longevity, UV DTF transfers cater to these needs, making them an excellent investment for businesses looking to elevate their product offerings.

Minimizing Waste with UV DTF Technology

Unlike traditional printing techniques that often result in significant waste due to ink overuse or inadequacies in the adhesion process, UV DTF technology is designed to minimize such waste. The immediate curing of inks significantly reduces the amount of ink that could potentially be wasted during the printing process. As businesses strive towards more sustainable practices, this eco-friendly aspect of UV DTF transfers becomes increasingly appealing.

Such efficiency not only contributes to environmental conservation but also translates into cost savings for businesses. Reduced material wastage means businesses can allocate resources more effectively, ultimately leading to greater profitability. This comprehensive advantage positions UV DTF transfers as an attractive and responsible choice for companies keen to embrace sustainable printing solutions.

Enhancing Production Efficiency with UV DTF Transfers

Production efficiency is a critical concern for many companies in the printing industry, and UV DTF transfers present a solution. By utilizing immediate curing technology, this method allows for significantly quicker turnaround times compared to traditional processes. As a result, businesses can manage tight deadlines and respond faster to customer demands while still upholding high quality in their deliverables.

The speed of production not only boosts client satisfaction by meeting expedited requests but also enhances workflow within the printing shop. Staff can focus on handling more orders, leading to increased output without compromising the integrity of the products. Overall, adopting UV DTF transfers empowers businesses to enhance their operational efficiency in ways that were previously unattainable.

Frequently Asked Questions

What are UV DTF transfers and how do they improve custom printing?

UV DTF (Direct to Film) transfers utilize advanced ultraviolet inks for high-quality printing, enabling vibrant designs on various materials. This technology enhances custom printing by providing superior detail, durability, and versatility compared to traditional methods.

Why should businesses consider using UV DTF for high-quality printing?

Businesses should consider UV DTF transfers for high-quality printing due to their ability to produce sharp, vivid images that capture intricate details. This print quality can significantly enhance branding, making it an excellent choice for logos and promotional materials.

What materials can be used with UV DTF transfers?

UV DTF transfers are remarkably versatile, allowing printing on a wide range of materials, including fabrics, plastics, metals, wood, and glass. This adaptability makes them ideal for creating unique custom products without the limitations of traditional printing.

How durable are prints made with UV DTF technology?

Prints made with UV DTF technology are exceptionally durable due to the immediate curing process, which protects them from fading, scratching, and environmental wear. This longevity makes them suitable for items exposed to regular use or outdoor conditions.

Is UV DTF printing a sustainable option for custom printing needs?

Yes, UV DTF printing is a sustainable option as it produces less waste than traditional methods. The efficient curing process minimizes ink waste and lowers the environmental impact of custom printing, aligning with eco-friendly practices.

What are the benefits of faster turnaround times with UV DTF transfers?

The rapid curing of UV inks enables faster production rates, allowing businesses to fulfill orders quickly without compromising quality. This efficiency enhances customer satisfaction and can lead to increased repeat business.

| Key Points | Details |

|---|---|

| Introduction | UV DTF transfers are set to revolutionize the custom printing industry by offering superior quality, versatility, and sustainability. |

| High-Quality Printing | Delivers sharp and vivid images suitable for branding and detailed graphics. |

| Material Versatility | Can print on a variety of substrates including fabrics, plastics, metals, and glass. |

| Durability | Resistant to fading and scratching, ideal for items exposed to wear and tear. |

| Reduced Waste | Minimizes failed prints and reduces cleanup time, making the process more eco-friendly. |

| Faster Turnaround Times | Immediate curing of inks allows for quick production and delivery. |

| Recent Trends | Increasing investment in UV DTF technology and expanding applications beyond textiles. |

| Challenges | High initial investment and required training for efficient operation. |

Summary

UV DTF Transfers are rapidly emerging as a pivotal element in the custom printing industry. Combining unparalleled print quality, versatility across various substrates, and enhanced durability, UV DTF technology meets the rising demand for more efficient and sustainable printing solutions. As industry trends lean towards innovation and eco-friendliness, UV DTF transfers are not just a trend but a significant leap forward in custom printing. Businesses that aim to keep pace with market demands and customer expectations should consider integrating UV DTF technology into their services, ensuring they remain competitive and relevant in a fast-evolving landscape.