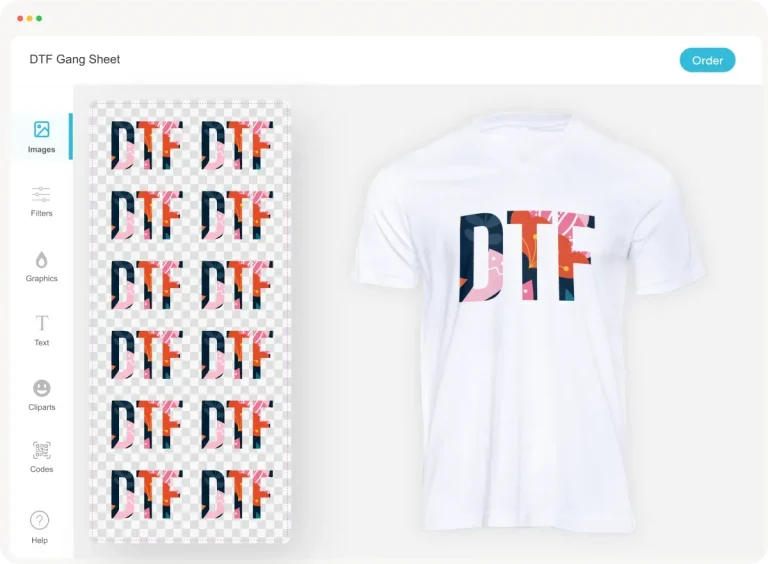

In the dynamic landscape of textile printing, the **DTF Gangsheet Builder** stands out as an essential tool that streamlines the Direct-to-Film (DTF) printing process. This innovative solution allows users to create gang sheets effortlessly, enabling them to print multiple designs on a single film for more efficient production. DTF printing has gained popularity due to its versatility, vibrant color output, and cost-effectiveness, making the gang sheet approach a valuable asset for apparel printing businesses. By leveraging the DTF Gangsheet Builder, creators can minimize material waste while maximizing print quality and design possibilities. In this guide, we will explore the features and advantages of the DTF Gangsheet Builder, equipping you to enhance your textile printing endeavors.

When discussing the innovative DTF Gangsheet Builder, one may also refer to it as a printing software that aids in the creation of composite sheets for textile projects. This tool revolutionizes the process by hooking into the Direct-to-Film technology, facilitating the efficient arrangement of designs for gang sheets. As the demand for high-quality apparel and versatile fabric prints rises, utilizing such groundbreaking tools in digital textile printing allows for exceptional outcomes. The synergy of gang sheets and DTF printing enables users to cut costs and reduce production time effectively. In essence, the DTF Gangsheet Builder is a game-changing component for any creator looking to optimize their printing operations.

Understanding DTF Printing Techniques

Direct-to-Film (DTF) printing utilizes a specialized transfer film to create striking fabric designs. This process starts with printing an image onto a PET film coated with a layer of adhesive. The adhesive plays a crucial role in ensuring a solid bond between the ink and the fabric once it’s pressed. DTF printing’s incredible versatility allows it to be employed on a plethora of materials, including cotton, polyester, and even blends, making it a popular choice across various industries. Its ability to render detailed artwork with vivid colors adds to its appeal, distinguishing it from other textile printing methods.

In addition to its applicability across different fabric types, DTF printing is also celebrated for its cost-efficiency. By minimizing material wastage and optimizing resource utilization, DTF printing is a sustainable choice for businesses looking to enhance their printing operations. The result is not just more environmentally friendly practices but also substantial savings on production costs, making this method highly attractive, especially for small to medium-sized enterprises in the apparel printing sector.

Frequently Asked Questions

What advantages does the DTF Gangsheet Builder provide for textile printing?

The DTF Gangsheet Builder offers numerous benefits for textile printing, such as cost reduction by allowing multiple designs to be printed at once, time efficiency through simultaneous printing, and minimized waste by maximizing the use of transfer films. This makes it an essential tool in DTF printing.

How can I optimize my designs when using the DTF Gangsheet Builder?

To optimize your designs in the DTF Gangsheet Builder, start by selecting high-quality artwork that meets the resolution requirements. Use the builder’s layout features to arrange designs efficiently, ensuring proper alignment and spacing. Additionally, utilize any optimization tools within the software for best printing settings.

What types of materials can I use with DTF printing and the Gangsheet Builder?

DTF printing, when combined with the Gangsheet Builder, is versatile and can be used on various fabric types such as cotton, polyester, and fabric blends. This allows for a wide range of apparel printing options, catering to different client needs.

Is the DTF Gangsheet Builder suitable for beginners in textile printing?

Yes, the DTF Gangsheet Builder is designed to be user-friendly, making it suitable for beginners. Its intuitive interface and drag-and-drop functionality allow even those new to DTF printing to create professional-quality gang sheets easily.

What file formats are compatible with the DTF Gangsheet Builder?

Most DTF Gangsheet Builders support popular image file formats such as PNG and JPEG. When preparing your designs for import, ensure they are in one of these compatible formats to achieve the best results in your printing projects.

How does using gang sheets improve the DTF printing process?

Using gang sheets significantly improves the DTF printing process by enabling the printing of multiple designs on a single transfer film. This approach not only reduces printing costs and material waste but also speeds up production, making it a favorable choice for businesses aiming for efficiency.

| Key Points | Description |

|---|---|

| DTF Printing | A printing technique that transfers vibrant designs onto various materials. |

| Versatility | Applicable to various fabrics like cotton, polyester, and blends. |

| Vivid Colors | Produces bright and vibrant colors for standout artwork. |

| Cost-Effective | Reduces material waste compared to traditional printing methods. |

| Gang Sheets | Multiple designs printed on a single film transfer to save costs and minimize waste. |

| User-Friendly Builder | Easy interface for arranging graphic elements effectively on a gang sheet. |

| Preview Functionality | Allows users to preview layouts before printing to ensure quality. |

Summary

The DTF Gangsheet Builder is a transformative tool in the realm of textile printing, enabling users to efficiently create gang sheets that enhance the quality of their prints. This guide showcases how DTF printing takes advantage of vivid colors, versatility, and cost-effectiveness, while also streamlining the design process with user-friendly software. By mastering the DTF Gangsheet Builder, businesses can minimize waste and maximize their creative potential, positioning themselves favorably in the competitive printing landscape. Embrace the innovation that DTF Gangsheet Builder provides and unlock the full potential of your printing projects.