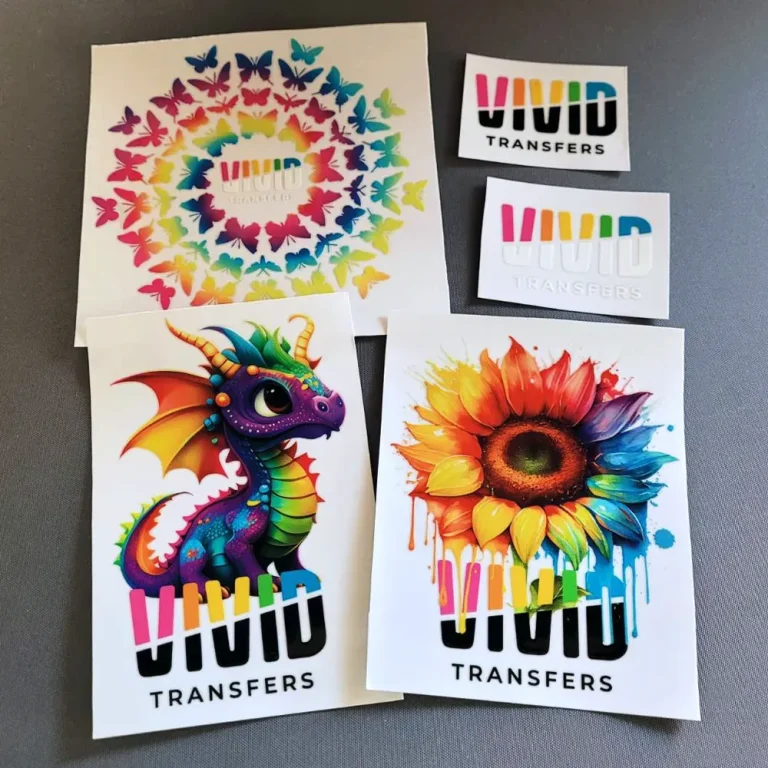

UV DTF transfers are revolutionizing the realm of custom garment printing by offering a superior alternative to traditional vinyl transfers. This innovative transfer printing technology allows for the application of intricate and vibrant designs directly onto a variety of fabrics, making it an ideal choice for businesses aiming to elevate their product offerings. The durability and quality of UV DTF prints are unmatched, providing long-lasting results that can withstand the test of time. As the demand for custom apparel continues to grow, understanding the nuances between vinyl vs DTF becomes crucial for selecting the best transfer method that meets your creative and budgetary needs. Whether you’re a small startup or an established brand, embracing UV DTF transfers can give you a significant edge in the competitive market of garment customization.

In today’s fast-paced world of textile printing, the demand for advanced transfer methods is on the rise. One such method, often referred to as direct-to-film transfers with ultraviolet curing, allows for high-definition imagery and vibrant colors to be easily applied to a range of fabrics. These techniques not only enhance creativity but also cater to a wide array of customization needs. On the other hand, classic vinyl transfer methods remain a popular choice among businesses for their simplicity and cost-efficiency, especially for straightforward designs. By comparing these innovative and traditional methods, one can make an informed decision on which lies at the forefront of garment printing technologies.

Understanding UV DTF Transfers in Custom Garment Printing

UV DTF transfers, or Direct to Film transfers, represent a significant advancement in the realm of custom garment printing technologies. This innovative method utilizes ultraviolet printing to apply bold and vibrant colors onto a special film, which can then be transferred to various fabric surfaces. The beauty of UV DTF lies in its ability to reproduce highly detailed images with a wide range of colors, making it ideal for intricate designs that need to stand out. This capability is critical for designers looking to push the boundaries of creativity in custom apparel.

In addition to their vibrant output, UV DTF transfers also boast durability that rivals other transfer methods. The UV curing process not only ensures high-resolution prints but also enhances the resilience of the designs against wear and washing. This makes UV DTF an optimal choice for businesses focused on delivering quality apparel that retains visual appeal over time. As the market becomes increasingly competitive, adopting technologies like UV DTF can give brands a significant edge.

Exploring the Benefits of Vinyl Transfers

Vinyl transfers have long been a staple in the custom printing industry, known for their simplicity and reliability. This method involves cutting colored vinyl sheets into desired shapes or texts and heat pressing them onto garments. The straightforward nature of vinyl transfers makes them particularly appealing to startups and small businesses looking for cost-effective solutions without sacrificing quality. They are particularly effective for sportswear and promotional items where logos or simple designs dominate.

The durability of vinyl transfers cannot be overstated. They are designed to withstand multiple washes without degrading, making them a preferred choice for items that undergo heavy use. However, potential users should be mindful of the limitations in design complexity inherent to vinyl transfers; intricate graphics are not easily managed, and color options can be restrictive. Nonetheless, for those seeking straightforward communication through apparel, vinyl remains a strong contender.

Comparing Pros and Cons: UV DTF vs. Vinyl Transfers

When evaluating the pros and cons of UV DTF transfers compared to vinyl transfers, it becomes clear that each method has its strengths and weaknesses. For example, UV DTF transfers allow for complex designs and a broader color gamut, making them suitable for artistic applications that require finesse. However, the initial cost for equipment and materials is higher, which could be a deterrent for smaller businesses or individual creators.

Conversely, vinyl transfers offer a more budget-friendly option, perfect for straightforward designs. Their durability and ease of production make vinyl a go-to for many projects, especially in bulk orders. However, the limitations in design complexity could hamper creatives aiming for more detailed work. Both methods serve their purpose well, but the choice ultimately depends on the specific needs of the project.

Latest Innovations in Transfer Printing Technologies

The landscape of transfer printing technologies is evolving rapidly, particularly with innovations in UV DTF transfers. Recent advancements have led to enhanced adhesion on various substrates and improvements in ink formulations, ensuring that prints are not just vibrant but also long-lasting. These developments signal a growing preference for UV DTF, especially among fashion-conscious businesses eager to differentiate their offerings in a crowded market.

Additionally, innovations aren’t limited to UV DTF alone; advancements in vinyl transfer technology also continue to emerge, making the process more streamlined and efficient. With increased capabilities for handling elaborate designs and faster production times, vinyl is seeing a resurgence in popularity as businesses recognize its potential in the competitive printing arena. As both technologies grow, staying updated with these trends ensures that businesses can make informed decisions on their transfer printing needs.

Choosing the Best Transfer Method for Your Needs

Selecting the best transfer method for your project involves evaluating several key factors, such as design complexity, project size, and budget. If your project leans toward intricate graphics and a diverse color palette, UV DTF transfers should be your choice. This technique excels in producing high-quality prints that do justice to complex designs, making them ideal for custom apparel with artistic flair.

On the other hand, if you focus more on budget considerations and simple designs, vinyl transfers present a cost-effective solution. Their ability to produce robust designs with longevity makes them practical for a variety of applications, especially in high-volume orders. As you analyze these elements, recognizing the unique benefits each method brings will help you make an informed decision.

The Future of UV DTF Transfers and Vinyl Transfers

The future of transfer printing technologies appears promising as UV DTF transfers and vinyl transfers continue to adapt to market demands. As businesses increasingly prioritize personalization and custom designs, UV DTF’s capabilities in producing vibrant, high-definition prints position it as a frontrunner. Furthermore, ongoing research and development might refine aspects such as curing times and substrate compatibility, making UV DTF even more attractive across different sectors.

Simultaneously, vinyl transfers are likely to see enhancements as technology advances. With a growing push towards eco-friendly materials and production methods, vinyl transfer manufacturers might explore sustainable options without compromising the quality and durability associated with this technique. As both UV DTF and vinyl transfers will likely evolve in tandem, staying ahead of industry trends and innovations will be pivotal for businesses seeking to capitalize on these methods.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers, or UV Direct to Film transfers, employ advanced UV printing technology to create vibrant designs on a specialized film substrate. This film can then be heat pressed onto fabric, allowing for intricate designs with a wide color gamut. The UV curing process enhances durability, making these transfers resistant to wear and tear.

How do UV DTF transfers compare to vinyl transfers?

UV DTF transfers are ideal for complex designs and vibrant colors, while vinyl transfers are better suited for simpler, text-based designs. Vinyl is often more cost-effective and widely used for logos because of its durability, although it lacks the versatility in color and detail that UV DTF transfers offer.

What are the advantages of using UV DTF transfers for custom garment printing?

The advantages of UV DTF transfers in custom garment printing include vibrant color reproduction, fast production times, and the ability to produce both small runs and personalized items efficiently. This method is particularly valuable for projects demanding intricate designs.

Are UV DTF transfers more expensive than vinyl transfers?

Yes, UV DTF transfers typically have higher initial costs due to the specialized equipment and materials required. However, they can provide superior quality and design capabilities that might offset these costs in longer-term projects, especially for intricate designs.

What design types are best suited for UV DTF transfers compared to vinyl transfers?

UV DTF transfers excel with intricate graphics and a variety of colors, making them suitable for detailed illustrations or multi-colored designs. In contrast, vinyl transfers work best with simpler designs and logos that do not demand multiple color layers.

What key factors should I consider when choosing between UV DTF transfers and vinyl transfers?

When choosing the best transfer method, consider factors such as design complexity, project size, and budget. UV DTF transfers are preferable for complex designs and vibrant prints, while vinyl transfers may be more cost-efficient for straightforward logo work or large runs.

| Key Points | UV DTF Transfers | Vinyl Transfers |

|---|---|---|

| Definition | Utilizes UV printing technology for vibrant images on film for heat pressing. | Involves cutting designs from colored vinyl sheets for heat pressing. |

| Pros | – Vibrant colors and wide color gamut. – Fast production time for urgent orders. – Suitable for short, personalized runs. |

– Cost-effective and budget-friendly. – Highly durable, withstands multiple washes. – Simple to execute for logos/text. |

| Cons | – Higher equipment and material costs. – Ongoing expenses for specialized ink/films. |

– Limited design complexity; labor-intensive for multi-layer colors. – Restricted color palette. |

| Ideal Use Cases | Complex designs with full-color images; suitable for fashion. | Simpler designs like logos; great for sportswear and promotional items. |

Summary

UV DTF Transfers have emerged as a favored option in garment printing thanks to their ability to produce high-quality, vibrant designs that can bring creativity to life. When choosing between UV DTF transfers and the more traditional vinyl transfers, consider your design complexity, budget, and production needs. UV DTF technology offers a sophisticated solution for intricate artwork, while vinyl transfers provide a cost-effective approach for simpler designs. Ultimately, the right transfer method will depend on your project’s unique requirements.