In the evolving landscape of garment decoration, understanding the best practices for DTF transfers by size is crucial for achieving high-quality results. Direct-to-Film (DTF) printing has emerged as a versatile option for customizing designs, allowing for a wide range of transfer sizes that cater to various fabrics and styles. By focusing on transfer size optimization, designers can enhance print resolution and avoid issues like pixelation or misalignment. The use of high DPI for printing ensures that each graphic element maintains its clarity, regardless of the scale. In this guide, we will delve into how mastering these size considerations can elevate the quality of your custom DTF transfers and streamline your workflow.

When we talk about optimizing DTF transfers, we refer to the critical practices that ensure successful and aesthetically pleasing garment applications. This includes understanding the nuances of Direct-to-Film printing, which has transformed how designs are applied to textiles, enabling a seamless fusion of art and fabric. Transfer size adjustments not only affect the visual impact but also play a significant role in the overall durability and adhesion of the print. By addressing factors like artwork scaling and fabric selection, businesses can create custom designs that resonate well with consumer preferences, maximizing satisfaction and efficiency in production. Ultimately, applying these principles will help you navigate the complexities of garment decoration in today’s competitive market.

Best Practices for DTF Transfers by Size

When it comes to Direct-to-Film (DTF) printing, understanding how to optimize transfer sizes is essential. DTF transfers are highly versatile, allowing businesses to create custom designs that can be applied to various garments. However, the key to successfully implementing DTF transfers by size involves knowing the capabilities and limitations of your printer. Most DTF printers can handle a range of transfer sizes; therefore, it’s crucial to determine the ideal dimensions based on the garment type and design intricacies.

Additionally, keeping in mind the DPI for printing is vital when working with different size transfers. High-resolution designs set at 300 DPI ensure that even larger prints maintain clarity and detail. A renowned best practice is to create a master template of common sizes and rigorously test artwork on different scales, adjusting them as necessary to prevent any loss of quality. Adhering to these practices allows businesses to leverage DTF technology effectively while meeting customer demands for customizations.

Understanding Print Area Limitations

The print area of a DTF printer plays a significant role in determining the sizes of the transfers you can create. Most DTF printers have specific print area limitations ranging from A4 to A3 and custom dimensions based on the machine’s specifications. Working within these limitations is necessary to avoid complications such as misaligned or incomplete transfers. Prior to initiating a DTF print job, it’s recommended to consult your printer’s manual to familiarize yourself with its specific print area capabilities.

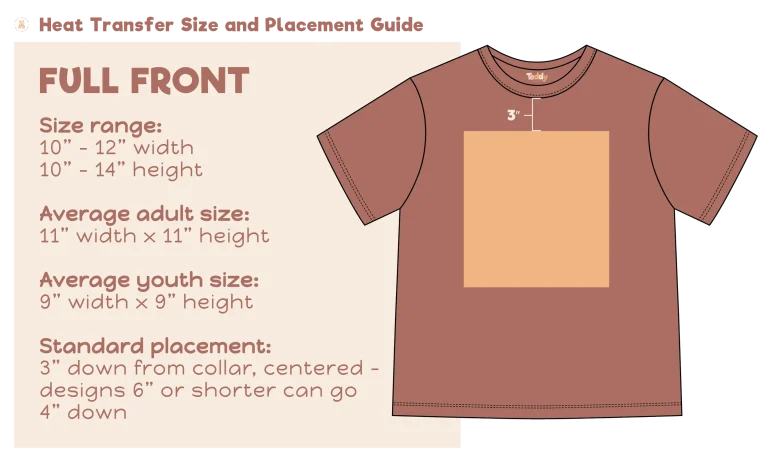

Moreover, optimizing the print area also requires an understanding of fabric types and how they interact with different transfer sizes. Larger prints tend to require more careful alignment and placement, especially on textured or uneven fabrics. Businesses should experiment with several print sizes within the available area to determine the best fit for their designs, ensuring a professional finish that captivates customers.

The Importance of Artwork Resolution

Artwork resolution is another critical aspect of DTF transfers, as it directly affects the final print quality. Ideally, artwork should be created or saved in high resolution—at least 300 DPI—to ensure that the details remain sharp and vibrant even when printed in larger sizes. Low-resolution graphics can lead to pixelation, especially in large prints, which diminishes the visual appeal of the final product.

To achieve the best results, designers should always test their artwork on fabric before finalizing a print run. This allows for adjustments in the design or resolution based on how it appears in an actual application. By prioritizing high-resolution artwork, you not only enhance the quality of your DTF transfers but also convey a professional image to your customers, establishing trust and repeat business.

Design Scaling and Proportionate Resizing

When scaling designs for different transfer sizes, maintaining the proportions is essential to avoid distortion. Many graphic design software tools offer functionality that assists in proportionate scaling, allowing designers to resize their artwork while keeping its integrity intact. Incorrect scaling can result in an unprofessional look, which is detrimental to brand reputation.

Additionally, testing various sizes through prototype prints can help designers make informed decisions about how the final product will appear. The growth in popularity of DTF printing means that staying true to the artwork’s original intent is critical; hence, proper scaling will not only save time but also resources by ensuring that mock-ups translate well onto fabric.

Fabric Considerations for DTF Transfers

The type of fabric chosen for a DTF transfer can significantly impact the transfer’s adherence and overall appearance. Fabrics such as cotton and polyester respond well to DTF techniques; however, as transfer size increases, the challenges of adhesion and durability also rise—especially on textured materials. Understanding the fabric’s properties is fundamental to achieving a successful outcome.

Furthermore, conducting trials with different fabric and transfer size combinations can lead to optimal results. By testing various materials, businesses can gather valuable data on which fabric types offer the best adherence and finish for specific sizes, ensuring that final products meet customer expectations. Effective communication with printing professionals can also provide insights on how to best approach material selection.

Streamlining Production Efficiency

For businesses engaged in large-scale DTF printing, optimizing production efficiency is key to maintaining profitability. When dealing with multiple transfer sizes, strategic planning around the arrangement of prints can minimize waste. This involves grouping similar sizes together on a single film, reducing the frequency of printer setup changes and increasing overall productivity.

Additionally, tracking customer preferences regarding transfer sizes can further enhance production efficiency. By analyzing sales data and customer feedback, businesses can streamline inventory management by focusing production on popular sizes while avoiding overproduction of less-demanded options. An efficient workflow not only saves resources but also maximizes output quality, ensuring satisfied customers in the competitive garment decoration market.

Frequently Asked Questions

What are the best practices for optimizing DTF transfers by size?

When optimizing DTF transfers by size, ensure you understand your printer’s size limitations and print area, select artwork with a resolution of at least 300 DPI, and maintain proportionate scaling in your designs. Testing prints in various sizes on different fabrics will help ensure quality and adherence.

How does print size impact the quality of DTF transfers?

The size of your DTF transfers directly affects the print quality; larger designs require higher resolution artwork to avoid pixelation. It’s essential to test the artwork at different sizes to ensure the final print is clear and meets your quality standards.

What adjustments should be made for larger DTF transfers?

For larger DTF transfers, adjust your heat press settings by increasing time, pressure, or temperature based on the manufacturer’s guidelines. Additionally, ensure the transfer adheres well to the fabric type chosen to avoid issues such as peeling or misalignment.

Why is artwork resolution important for DTF transfers?

Artwork resolution is crucial for DTF transfers because higher DPI values (at least 300 DPI) ensure your prints remain sharp and detailed, especially when scaled to larger sizes. Using high-resolution images helps maintain the integrity of your designs across various garment decorations.

What materials work best for different DTF transfer sizes?

DTF transfers adhere well to various materials such as cotton, polyester, and blends. However, larger transfers may require careful consideration of the fabric type, as textured fabrics may not hold larger prints as effectively. Testing different materials can aid in choosing the optimal combination.

How can I improve efficiency while producing DTF transfers in different sizes?

To enhance production efficiency for DTF transfers of varying sizes, group similar sizes on a single film to minimize waste. Additionally, track popular sizes and styles through customer feedback and align your production cycles accordingly to balance inventory management.

| Key Point | Details |

|---|---|

| Understanding Size Limitations | Comprehend printer size limitations, usually from A4 to custom sizes based on printer model. |

| Artwork Resolution | Artwork should be designed at least to 300 DPI to ensure clarity. |

| Design Scaling | Maintain aspect ratio when scaling to prevent distortion. |

| Material Considerations | Choose the transfer size according to fabric type to prevent adhesion issues. |

| Production Efficiency | Optimize workflow for batch production by grouping similar sizes. |

| Quality Control | Perform final inspections for sizing accuracy and print quality. |

Summary

Best practices for DTF transfers by size are essential for achieving optimal results in garment decoration. Understanding the limitations of your printing equipment, such as the maximum print area and the necessary artwork resolution, sets the foundation for quality output. Proper design scaling ensures that art maintains its intended appearance across different sizes, while material considerations guide the appropriate matching of transfer size to fabric type. With a strong focus on production efficiency and quality control, businesses can streamline their processes and enhance customer satisfaction. By following these best practices for DTF transfers by size, companies can elevate their printing solutions and meet the growing demands of their clientele.