Cost Comparison: DTF Transfers vs. Vinyl Transfers is a crucial topic for small business owners looking to maximize their profits while ensuring high-quality custom apparel printing. As the demand for personalized clothing continues to grow, understanding the financial implications of different printing methods becomes pivotal. DTF transfers provide an innovative solution that allows for vibrant and intricate designs, often at a more cost-effective price for larger runs compared to traditional vinyl transfers. In this article, we will analyze the cost differences, helping you to make an informed decision that aligns with your business goals and enhances your product offerings. Discover how both DTF and vinyl transfers can impact your small business printing strategy and overall customer satisfaction.

When it comes to selecting the best printing technique for your apparel needs, exploring alternatives like Direct-to-Film (DTF) printing and conventional vinyl applications is essential. These methodologies serve the same purpose—creating eye-catching designs on fabric—yet differ significantly in their operational costs, efficiency, and output quality. By examining the financial aspects, labor requirements, and durability standards associated with DTF and vinyl methods, you’ll gain valuable insights into which option best suits your small business model. Whether you seek cost-efficient printing methods for bulk orders or detailed custom work for individual requests, understanding the nuances between these two techniques will empower you to make the right choice for your venture.

The Advantages of DTF Transfers for Small Businesses

Direct-to-Film (DTF) transfers have revolutionized the custom apparel printing landscape, providing significant advantages for small businesses aiming to enhance their product offerings. One of the most notable benefits of DTF is its ability to render intricate designs with a high level of color vibrancy that is unmatched by traditional methods. This technique allows for designs containing multiple colors and gradients to be printed in one go, substantially reducing labor time and costs. As a result, businesses can maximize their output and cater to customer demands more effectively, setting themselves apart from competitors who rely on older printing technologies.

Moreover, DTF transfers offer flexibility that is crucial for small businesses. They can easily adapt to various fabric types, from cotton to polyester, which enable businesses to expand their product range beyond generic t-shirt printing. This adaptability, paired with the ease of producing both small and large quantities, makes DTF a cost-effective solution for startups aiming to make a mark in the crowded apparel industry. The low cost per transfer further amplifies its appeal, ensuring that even small runs can be financially viable.

Exploring Cost Comparison: DTF Transfers vs. Vinyl Transfers

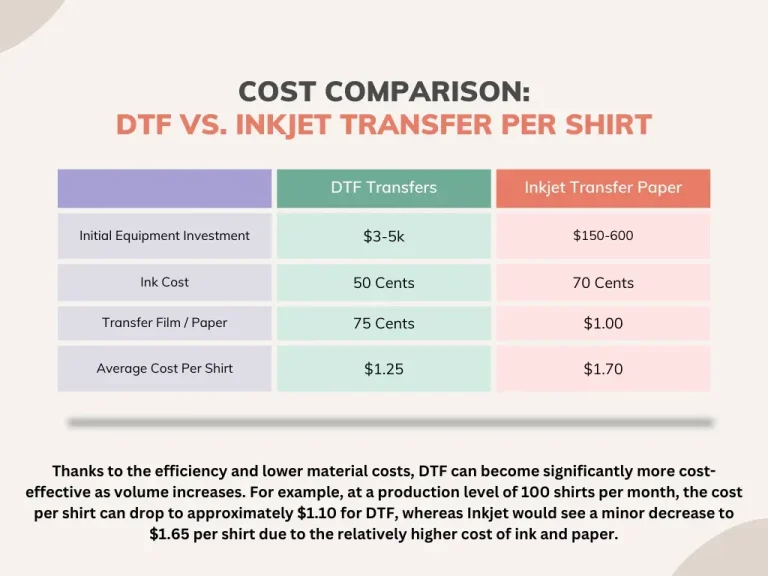

When it comes to cost comparison, DTF transfers present a compelling case against vinyl transfers, particularly for small businesses that frequently deal with larger orders. The initial investment in DTF printing may be higher due to the necessary equipment, which can be daunting for new entrepreneurs. However, as production scales, the cost per transfer significantly decreases, often falling between $1.00 and $1.50. This metric is critical for businesses that prioritize efficiency and profitability, especially when preparing bulk orders for customers.

In contrast, while vinyl transfers require a lower initial investment and showcase a cost per transfer ranging from $0.50 to $1.00, the labor-intensive process can drive up overall costs. Each design must be meticulously cut, weeded, and applied, which can delay production and increase the need for labor. Thus, while vinyl transfers may seem economical at first glance, the hidden costs associated with labor and longer turnaround times can make DTF a more financially sound choice for businesses focused on scaling and diversifying their product lines.

Labor Efficiency in DTF Transfers: A Game Change for Small Businesses

Labor efficiency is one of the key factors that can sway small business owners toward adopting DTF transfers. The DTF printing process streamlines workload by enabling the creation of multi-colored and complex designs in a single step. This efficiency translates into faster production times, allowing businesses to fulfill orders more quickly and meet customer demands without sacrificing quality. The ability to input sophisticated designs into the printer reduces manual labor significantly, freeing up employees to focus on other areas of production and customer service.

In contrast, vinyl transfers commonly entail a more tedious production workflow. Each design goes through several steps, from cutting to weeding to heat pressing, which can not only prolong production but also strain staffing resources, especially during peak buying seasons. The labor-intensive nature of vinyl transfers makes them less appealing for small businesses aiming to increase output without heavily investing in labor. Therefore, opting for DTF technology can boost overall labor efficiency, making it an advantageous choice for small enterprises looking to grow.

Quality and Durability: Ensuring Customer Satisfaction with DTF Transfers

Quality and durability are the cornerstones of customer satisfaction in the custom apparel industry. DTF transfers excel in this area by offering vivid colors and intricate details that stand the test of time. When applied correctly, DTF prints maintain their opacity and vibrance through numerous washes, making them ideal for everyday wear items like t-shirts and sports jerseys. In an industry where repeat business hinges on product longevity, DTF technology provides an assurance of quality that is hard to replicate with traditional methods.

On the other hand, vinyl transfers, while visually appealing due to their distinct layered finishes, can face challenges in terms of durability. Factors such as peeling, cracking, and fading can emerge if vinyl designs are improperly applied or subjected to harsh washing conditions. Small businesses that prioritize quality must understand these limitations, as customer dissatisfaction stemming from product defects could harm their reputation. Thus, investing in DTF transfers could enhance product quality, ensuring customer loyalty through durable, high-quality apparel.

Current Market Trends: The Rise of DTF Transfers in Custom Apparel Printing

The custom apparel market is witnessing a substantial shift toward DTF transfers, indicating a transformation in consumer preferences and market demands. As businesses transition to DTF technology, they unlock opportunities to produce more intricate designs without escalating costs. This trend is driven by small businesses striving for flexibility and efficiency to stay relevant. With DTF offering cost-effective solutions, entrepreneurs can address a diverse clientele looking for unique and visually striking apparel.

Moreover, as DTF technology evolves, small businesses will increasingly adopt this innovative printing method, leading to higher competitiveness within the industry. The versatility of DTF allows small print shops to meet the growing consumer demands for personalization and customization, presenting a significant opportunity to expand their market share. As vinyl transfers fade slightly in popularity, it is vital for small businesses to embrace these market trends and adapt their printing techniques accordingly to thrive in a competitive environment.

Choosing the Right Printing Method for Your Custom Apparel Business

Making the right choice between DTF transfers and vinyl transfers is crucial for small businesses aiming to maximize their potential in the custom apparel market. This decision should be guided by evaluating multiple aspects such as production volume, design complexity, operational costs, and customer preferences. For businesses frequently producing large quantities of intricate designs, DTF printing is likely the optimal choice, delivering on efficiency and lowering per-transfer costs.

Conversely, if a business mentality focuses on creating limited runs of simpler designs, then vinyl transfers may still hold merit due to their lower barrier to entry and less complex production demands. Ultimately, assessing the specific needs of the business, alongside thorough market research and testing both methods, will lead entrepreneurs to a choice that aligns with their strategic goals and operational capabilities.

Frequently Asked Questions

What are the cost comparisons between DTF transfers and vinyl transfers for small businesses?

When comparing DTF transfers and vinyl transfers, initial investment costs differ significantly. DTF printers range from $25,000 to $50,000, while starting a vinyl transfer setup may cost around $1,000. However, per transfer costs for DTF are between $1.00 and $1.50, making it more cost-effective for larger orders, while vinyl transfers usually cost $0.50 to $1.00 per transfer.

How do labor requirements differ between DTF transfers and vinyl transfers?

DTF transfers require less labor compared to vinyl transfers since multiple colors and intricate designs can be printed in one pass. This efficiency results in faster production times. Conversely, vinyl transfers are labor-intensive due to the need for cutting and weeding each design, which can increase labor costs, particularly for complex designs.

What is the durability difference between DTF transfers and vinyl transfers?

DTF transfers are known for vibrant colors and high durability, often lasting through numerous washes without significant fading. Vinyl transfers, while visually appealing, may face issues like cracking and peeling over time if not applied correctly, which may affect their long-term durability compared to DTF prints.

Why might small businesses prefer DTF transfers over vinyl transfers?

Small businesses may prefer DTF transfers due to their ability to produce complex designs more efficiently, especially in bulk. Lower cost per transfer for larger orders makes DTF a cost-effective choice, and growing market trends show a shift towards DTF due to these advantages.

Are DTF transfers suitable for all types of apparel printing?

Yes, DTF transfers are suitable for a wide range of apparel printing due to their ability to handle multi-color designs and intricate patterns. They are especially effective for items requiring durability, like sports jerseys, making them a versatile choice in custom apparel printing.

What kinds of businesses should consider vinyl transfers instead of DTF transfers?

Vinyl transfers might be better suited for small businesses focusing on lower volumes of custom designs or simpler graphics. If precision is crucial and the order volume is not high, vinyl transfers can provide quality and personalized designs effectively without the higher initial investment associated with DTF technology.

| Key Factor | DTF Transfers | Vinyl Transfers |

|---|---|---|

| Initial Investment | $25,000 – $50,000 | ~$1,000 |

| Cost Per Transfer | $1.00 – $1.50 | $0.50 – $1.00 |

| Labor Efficiency | High – multiple colors in one pass | Low – time-consuming with cutting and weeding |

| Quality & Durability | High – vibrant colors, withstands washes | Moderate – can crack or peel if not applied properly |

| Current Market Trends | Growing preference for complex designs | Still used for simpler graphics and custom designs |

Summary

Cost Comparison DTF Transfers Vinyl Transfers is crucial for small businesses aiming to optimize their print production processes. As highlighted, DTF transfers offer a higher initial investment but lower material costs per transfer, providing long-term cost benefits when producing complex designs. On the other hand, vinyl transfers require a significantly lower entry cost but can lead to higher labor expenses and longer production times for detailed designs. The decision ultimately depends on your business’s specific needs, focusing on order volume and design complexity, allowing you to choose the best method that aligns with your operational goals.