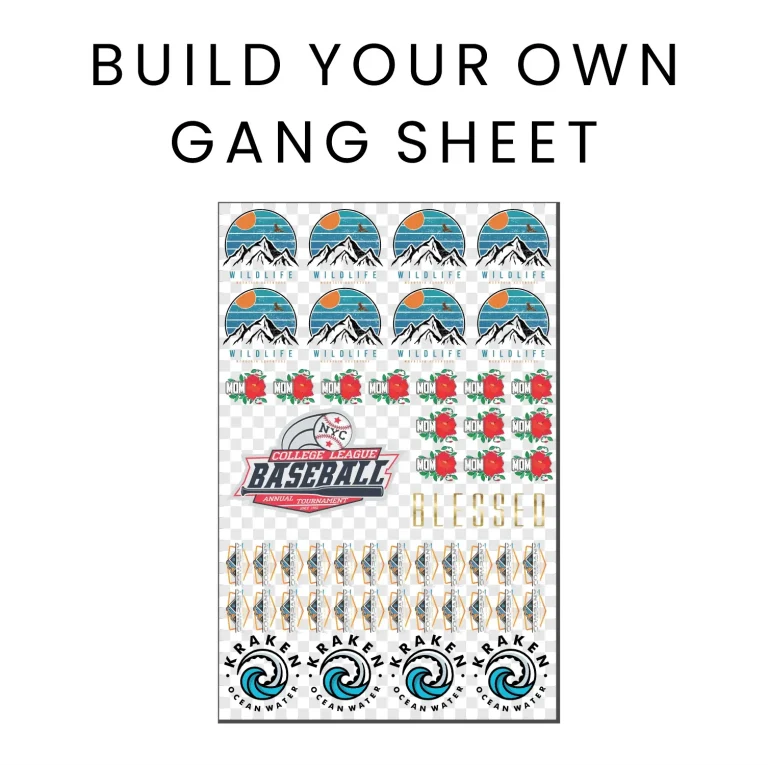

If you’re looking to unleash your creativity with fabric printing, then DIY DTF gangsheet projects should be on your radar. This innovative approach to DTF printing allows you to group multiple designs on a single sheet, maximizing both efficiency and creativity. With our detailed customization tutorial, you’ll learn how to create vibrant, high-quality prints that stand out. From understanding gangsheet printing nuances to mastering vital heat press techniques, this guide will equip you with all the knowledge you need for successful DIY printing. Whether you’re a hobbyist or aspiring entrepreneur, the world of DTF gangsheeet offers limitless possibilities for customization.

DTF gangsheet printing, often referred to as direct-to-film gangsheet design, transforms the way we think about fabric customization. By combining several unique graphics into one printable sheet, you not only streamline your workflow but also enhance cost-effectiveness. This versatile method of customization allows users to explore an array of designs while maintaining high-quality output. Whether you’re delving into DIY printing for personal projects or small business ventures, mastering these printing techniques will elevate your creative endeavors. In this guide, we will reveal comprehensive insights and tips to empower your customization journey.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is a game-changing technology in the realm of custom fabric production. Unlike traditional methods, DTF allows for vibrant, full-color prints that can be applied to a wide range of materials, from cotton and polyester to blends and specialty fabrics. The process involves printing your design onto a unique film combined with special inks that bond effectively with textiles. This versatility makes DTF a preferred choice for hobbyists and small businesses looking to offer custom apparel.

One of the main advantages of DTF printing is its ability to produce intricate designs without the need for screens, making it more efficient for multiple designs. This printing method not only delivers stunning visuals but also reduces production time significantly. As you become familiar with DTF, you’ll appreciate its capability to cater to both large-scale orders and one-off creations seamlessly.

The Advantages of Using a Gangsheet for DIY Projects

Utilizing a gangsheet in your DIY DTF projects can dramatically enhance your production efficiency. By printing multiple designs on a single sheet, you minimize waste and maximize the use of your DTF supplies. This approach is particularly beneficial for those creating various designs on a budget. Instead of printing each design separately, which can lead to excess film and ink usage, a gangsheet allows for consolidated production, saving both resources and time.

Additionally, a gangsheet simplifies the overall printing process. When you prepare your designs thoughtfully, you can ensure that they fit seamlessly on the sheet, reducing the complexity involved in setup and printing. This method is not just cost-effective; it also streamlines the transition from design to application, enabling you to focus on your creativity rather than logistics.

Essential Tools for Successful DTF Customization

To embark on your DTF customization journey, having the right tools is paramount. A compatible DTF printer is essential; it needs to be capable of handling the specific film and inks designed for this process. Alongside the printer, you will require high-quality DTF inks that ensure vibrant color reproduction and durability. Investing in a reliable heat press machine is equally crucial, as it plays a vital role in effectively transferring your prints onto fabric.

Moreover, don’t overlook the importance of graphic design software. Programs like Adobe Illustrator or CorelDRAW allow you to manipulate your designs for optimal printing results. Being adept in utilizing tools such as layers and color adjustments will significantly improve the quality of your final product. These tools, combined with your creativity, will lay the foundation for exceptional DTF prints.

Step-by-Step Guide to Creating Your Own DTF Gangsheet

Creating your very own DIY DTF gangsheet is a rewarding process that begins with careful design preparation. Start by generating high-resolution images compatible with DTF specifications. It’s essential to set your design dimensions correctly and ensure that you’re aware of color limitations in your chosen palette. Tools like Adobe Illustrator provide excellent features for layering designs and ensuring color accuracy.

After your designs are ready, arranging them on a template within your design software effectively is the next step. Using grid features can help you align your designs for maximum use of the film. It’s advisable to leave ample space between each design to prevent any overlap, ensuring a clean transfer on the fabric. With your gangsheet set up, you’ll be ready to print and press your creations seamlessly.

Printing Techniques for Optimal Results

The printing process in DTF customization is a critical step that requires attention to detail. Once your gangsheet is prepared, load the transfer film into your DTF printer. It’s vital to adjust the printer settings for DTF-specific printing to achieve the best quality. Ensure your printer is clean and calibrated for accurate color reproduction. Printing at the right resolution will yield sharp, vivid images that stand out on fabric.

After printing, apply adhesive powder while the ink is still wet. This powder is vital as it helps the design adhere firmly to the fabric during the heat pressing phase. Following the correct application techniques can significantly influence the longevity and quality of the printed designs. Being meticulous at this stage will pay off with flawless, high-quality results once the film is pressed onto your chosen fabric.

Maintaining Quality in Your DTF Customization Projects

For successful DTF customization, quality control is essential at every stage—from design to final application. Make it a practice to regularly check the resolution and clarity of your images. Any discrepancies in visual quality can affect the outcome of your prints, leading to dissatisfaction with the final product. Additionally, staying informed about different fabric types and their heat settings will help ensure that your designs adhere properly and maintain their vibrant colors wash after wash.

Educating yourself on potential pitfalls in the DTF process can also bolster your success. Frequent issues can include misalignment during the heat press or inadequate ink saturation. By continually honing your practices and techniques, as well as gathering feedback from peers or craft communities, you’ll be in a stronger position to produce high-quality, custom designs that truly reflect your creative vision.

Frequently Asked Questions

What are the key benefits of using a DIY DTF gangsheet in custom apparel printing?

Using a DIY DTF gangsheet allows you to print multiple designs on a single sheet, optimizing material usage and minimizing waste. This approach is cost-effective for small businesses or hobbyists, enhancing productivity by allowing quicker setup and printing for various designs.

How do I set up my designs for a DTF gangsheet?

To set up your designs for a DTF gangsheet, arrange them on a single template in graphic design software. Leave adequate space between each design to prevent overlap and utilize grid features for alignment. Ensuring high-resolution graphics will optimize print quality.

What steps are involved in printing a DIY DTF gangsheet?

The steps to print a DIY DTF gangsheet include creating your designs, setting them up on a template, printing them on DTF transfer film, applying adhesive powder, and finally heat pressing the designs onto your chosen fabric.

What equipment is necessary for effective DIY DTF printing?

For effective DIY DTF printing, you need a DTF printer, specialized DTF inks, transfer film, adhesive powder, a reliable heat press machine, and graphic design software like Adobe Illustrator to create and optimize your designs.

Can I customize various fabric types using DTF printing?

Yes, DTF printing is highly versatile and can be used on various fabric types, including cotton, polyester, and blends. It’s important to check the compatibility of your fabrics with the heat press techniques to achieve the best results.

Where can I find tutorials for DIY DTF gangsheet printing?

You can find excellent tutorials for DIY DTF gangsheet printing on platforms like YouTube, where channels such as ‘Silhouette School’ and ‘Heat Transfer Warehouse’ offer comprehensive guides, along with community forums where you can learn from experienced users.

| Key Points | Details |

|---|---|

| DTF Printing Overview | DTF printing transfers designs onto fabric via a special film, allowing for vibrant, detailed prints. |

| Gangsheet Concept | A gangsheet enables multiple designs to be printed together, promoting material efficiency and reduced costs. |

| Essential Tools | DTF printer, ink, transfer film, adhesive powder, heat press machine, graphic design software. |

| DIY Steps | 1. Design your graphics in design software. 2. Setup the gangsheet by arranging designs. 3. Print using DTF printer. 4. Apply adhesive and heat press. |

| Tips for Success | Experiment with designs, check material compatibilities, and maintain quality control during printing. |

Summary

DIY DTF gangsheet creation offers an exciting opportunity to bring your unique designs to life while saving time and resources. This innovative printing technique allows for the production of stunning apparel, making it perfect for enthusiasts or small businesses aiming to express individual styles. By understanding the steps involved in designing, printing, and applying your gangsheet, you can fully harness the potential of DTF customization. With practice and the right tools, you can enjoy a seamless experience in transforming your creative ideas into vibrant, wearable art.