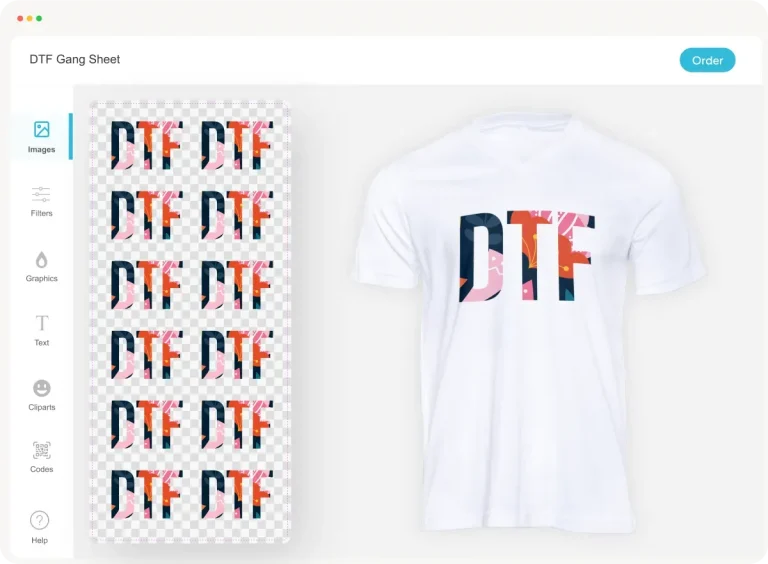

In the dynamic realm of garment printing, the DTF Gangsheet Builder stands out as a revolutionary tool that empowers designers to unleash their creativity. This innovative method streamlines the printing process by allowing multiple stunning designs to be efficiently printed on a single transfer film sheet. Not only does the DTF gangsheet approach significantly reduce waste, but it also enhances cost-effectiveness, making it a preferred choice for businesses. In this article, we will delve into best practices for utilizing the DTF Gangsheet Builder, focusing on effective design preparation and execution. Join us as we explore how to create eye-catching artwork while optimizing your printing workflow.

The Direct to Film (DTF) Gangsheet Builder is an essential resource for those involved in custom apparel design and production. This method leverages gang sheet printing capabilities, enabling creators to optimize their designs for garment printing efficiently. By utilizing this technique, you can enhance productivity and streamline the design preparation process—ensuring that your graphics stand out across various fabric types. With a focus on stunning designs and eco-friendly practices, this printing solution is gaining traction among both small businesses and established brands looking to make their mark in the industry. Discover the immense benefits and best practices associated with this versatile printing method.

Understanding DTF Printing Techniques

DTF (Direct to Film) printing is revolutionizing the garment industry with its exceptional versatility and quality. The key concept behind DTF printing is the ability to transfer vibrant designs onto a variety of fabrics, creating stunning and long-lasting prints. By using specialized films and inks, DTF printers can produce intricate details that are often hard to achieve with traditional printing methods. This technique enables designers to unleash their creativity, ensuring that every piece of apparel reflects unique artistry and style.

Moreover, DTF printing allows for a broader range of fabric applications, including cotton, polyester, and blended materials. This flexibility makes it the perfect solution for custom apparel businesses seeking to cater to various market demands. With its growing popularity, understanding DTF printing techniques is crucial for anyone in the garment printing industry, as it opens up limitless potential for design and innovation.

The environmental impact of traditional printing methods often raises concerns, but DTF printing takes strides towards sustainability. By using water-based inks and recyclable transfer films, it not only minimizes waste but also improves the ecological footprint of the garment printing process. As brands increasingly adopt sustainable practices, DTF printing becomes an attractive option that aligns with consumer demand for eco-friendly choices.

In conclusion, the understanding of DTF printing techniques enables designers and businesses to leverage the advantages of this innovative method, ultimately enhancing their market position and consumer appeal.

Maximizing Your DTF Gangsheet Layout

Design layout optimization is crucial when utilizing the DTF Gangsheet Builder. By maximizing the space on your gang sheet, you can print multiple designs simultaneously, reducing wastage and lowering production costs. To achieve this, designers must focus on key aspects such as alignment and spacing, which play a significant role in the printing process. Properly spaced designs ensure that each artwork retains its integrity during the heat transfer, resulting in beautiful, clean finishes on garments.

Another vital tip for maximizing your DTF gangsheet layout is to group similar designs together. This not only saves space but also streamlines the workflow during the printing process. By organizing designs according to color schemes or sizes, you can efficiently use the transfer film while maintaining high-quality outputs. A well-planned layout ultimately leads to increased efficiency in production, allowing for faster turnaround times and satisfying customer demands.

The digital tools available in the DTF Gangsheet Builder further enhance layout optimization. With features that enable designers to preview and adjust their layouts before printing, users can easily experiment with different arrangements. Such flexibility ensures that the final design adheres to professional standards, resulting in a polished product that captivates consumers.

In summary, maximizing your DTF gangsheet layout not only improves production efficiency but also enhances the quality of the final prints, allowing businesses to thrive in a competitive market.

Best Practices for DTF Design Preparation

Effective design preparation is the foundation for creating stunning DTF prints. To ensure the best results, it is essential to employ vector-based graphics when developing designs. Vector images are infinitely scalable without losing quality, making them ideal for the dynamic nature of garment printing. By starting with high-resolution graphics, you ensure that every detail shines through in the final product, showcasing the intricacies of your designs.

Another critical aspect of design preparation is the choice of color mode. Utilizing the CMYK color model is crucial to ensure that your colors are accurately reproduced in the printing process. Ensuring that your design files are set to 300 DPI or higher will result in prints that are vibrant and true to the original artwork. By adhering to these best practices, designers can significantly enhance the visual appeal of their garments while optimizing the DTF printing workflow.

Beyond graphical elements, thoughtful design layout also plays an important role in preparation. Aligning and organizing designs to occupy minimal space on the gang sheet not only maximizes efficiency but also reduces material waste. This meticulous attention to detail ensures that the printing process proceeds smoothly, leading to high-quality outputs that resonate with your target audience.

In conclusion, best practices for DTF design preparation lay the groundwork for stunning prints, ensuring that every piece produced meets the aesthetic expectations of consumers while adhering to environmental sustainability.

Selecting Appropriate File Formats for DTF Printing

Choosing the right file formats is essential for successful DTF printing, and understanding the intricacies of various formats can significantly affect the outcomes. PNG files are widely recommended due to their ability to support high-quality images and transparency, which is crucial for creating intricate designs. When preparing files for printing, it is important to flatten images to eliminate any layers that could complicate the printing process. A single, clean file ensures that your design is ready for accurate reproduction on the gang sheet.

In addition to PNG, other formats like AI (Adobe Illustrator) can also be beneficial for creating DTF designs, especially when working with vector graphics. These formats retain the scalability of artwork necessary for high-quality outputs. Regardless of the file format chosen, ensuring that all images are print-ready before sending them to the printer can save time and resources, leading to a more efficient production process.

As businesses increasingly embrace DTF printing, the need for compatibility and readiness of design files becomes pivotal. Analyzing the specific requirements of your DTF printer can provide insights on which file types yield the best results. By ensuring that your designs are in the correct formats and optimized for printing, you set the stage for successful garment printing that captures the market’s attention.

In summary, selecting appropriate file formats is crucial for DTF printing success, playing a significant role in achieving stunning designs that meet consumer demands.

Navigating DTF Heat Transfer Techniques

Heat transfer techniques are fundamental to the successful application of DTF prints onto garments. Properly understanding the temperature and pressure settings required for each specific DTF ink type is crucial for ensuring optimal adhesion and longevity of the prints. Following the guidelines provided by your ink supplier not only guarantees adherence but also preserves the vibrancy of colors in your designs. Keeping up with these specifics allows designers to produce prints that withstand the test of time and usage.

Additionally, material consideration is necessary to achieve the best results with heat transfer applications. Different fabrics have varying heat tolerance levels and require tailored settings to prevent damage during the transfer process. For example, materials like polyester may require lower temperatures to avoid melting, whereas cotton might allow for higher heat settings. Understanding the nuances of various fabric types allows for more precise application of heat transfer, resulting in stunning and durable prints.

Incorporating thermal paper oxygenation into the process can further yield outstanding results, enhancing the color vibrancy. As heat activates the inks, ensuring uniform application across the fabric is key, allowing the designs to pop. Regular checks and calibration of your equipment before printing also play an essential role in achieving flawless results.

In conclusion, mastering DTF heat transfer techniques is imperative for effective and impressive garment printing, ensuring vibrant, well-adhered designs even through extensive use.

Current Trends in DTF Printing Technology

The DTF printing landscape is in constant evolution, with new trends shaping the future of garment printing. One notable trend is the rising demand for custom apparel due to its personal touch and unique designs. Consumers are increasingly seeking personalized fashion choices, which has led to innovative uses of the DTF Gangsheet Builder in creating stunning designs that cater to individual preferences. This shift emphasizes the importance of staying ahead of the curve for brands looking to remain competitive.

Another significant trend is the emphasis on sustainability within the DTF printing industry. As consumers become more environmentally conscious, businesses are responding by adopting eco-friendly materials and practices. The use of water-based inks and recyclable transfer films not only meets consumer expectations but also helps reduce the overall carbon footprint of the printing process. As brands prioritize eco-friendly practices, the DTF gangsheet approach offers a feasible solution that aligns with sustainable values.

Furthermore, advancements in technology continue to pave the way for greater efficiency and quality in DTF printing. The integration of Artificial Intelligence in design preparation and layout optimization is revolutionizing how designers approach their work. This embracing of technology allows for more intricate design possibilities while ensuring that the prints remain vibrant and appealing.

In summary, the current trends in DTF printing technology reflect the industry’s move towards customization and sustainability, showcasing the importance of adapting to changing consumer demands for businesses aiming to succeed.

Frequently Asked Questions

What are the main advantages of using the DTF Gangsheet Builder for garment printing?

The DTF Gangsheet Builder offers numerous benefits such as reducing waste by maximizing the use of transfer films, improving cost efficiency by allowing multiple designs on a single sheet, and producing vibrant, high-quality prints that are suitable for various fabrics. This makes it an ideal choice for custom apparel businesses.

How do I prepare designs for the DTF Gangsheet Builder?

To prepare designs for the DTF Gangsheet Builder, use vector-based graphics to ensure scalability, follow the CMYK color model for accurate printing, and maintain high resolution (300 DPI or higher). Organize your designs efficiently on the gang sheet to minimize waste and optimize space.

What file formats are recommended for DTF printing with the Gangsheet Builder?

For DTF printing, PNG files are highly recommended due to their support for transparency and high-quality images. Ensure that your designs are flattened and print-ready before submitting them for printing with the DTF Gangsheet Builder.

What are the best practices for layout optimization in DTF gang sheet printing?

To optimize your layout in DTF gang sheet printing, maintain appropriate spacing between designs to avoid cutting issues during the heat transfer. Additionally, ensure proper alignment to minimize wasted materials and maximize the number of designs per sheet.

What should I consider during the printing process using the DTF Gangsheet Builder?

During the printing process, it’s essential to calibrate your DTF printer accurately for precise color reproduction, conduct test prints on the intended material to check for color accuracy, and ensure that high-quality inks are used for optimal results.

How can heat transfer techniques affect my designs using the DTF Gangsheet Builder?

Heat transfer techniques are crucial for successful adhesion of designs to fabric. Make sure to follow recommended temperature and pressure settings for your DTF inks, and consider the fabric type since different materials may require specific heat application settings.

| Key Points | Details |

|---|---|

| What is DTF Gangsheet? | A printing technique that allows multiple designs on a single transfer film, optimizing material usage and reducing costs. |

| Best Practices | 1. Design Preparation: Use vector graphics and CMYK color mode. 2. Layout Optimization: Maintain space between designs to prevent cutting. 3. File Formats: Use PNG files for high-quality outputs. 4. Printing Process: Ensure printer calibration and conduct test prints. 5. Heat Transfer: Adjust settings based on fabric type for best adherence. |

| Current Trends | 1. Rise in Popularity: High-quality output on various fabrics. 2. Eco-Friendly Materials: Growing preference for sustainable inks and recyclable films. |

Summary

The DTF Gangsheet Builder is revolutionizing the way designers approach garment printing, making it easier to create vibrant and sustainable designs. By adhering to best practices in design, layout, and printing techniques, businesses can maximize efficiency and minimize waste, ensuring high-quality results for their custom apparel. As DTF technology continues to advance, embracing these methods will not only enhance your creative output but also keep you competitive in the ever-evolving printing industry.