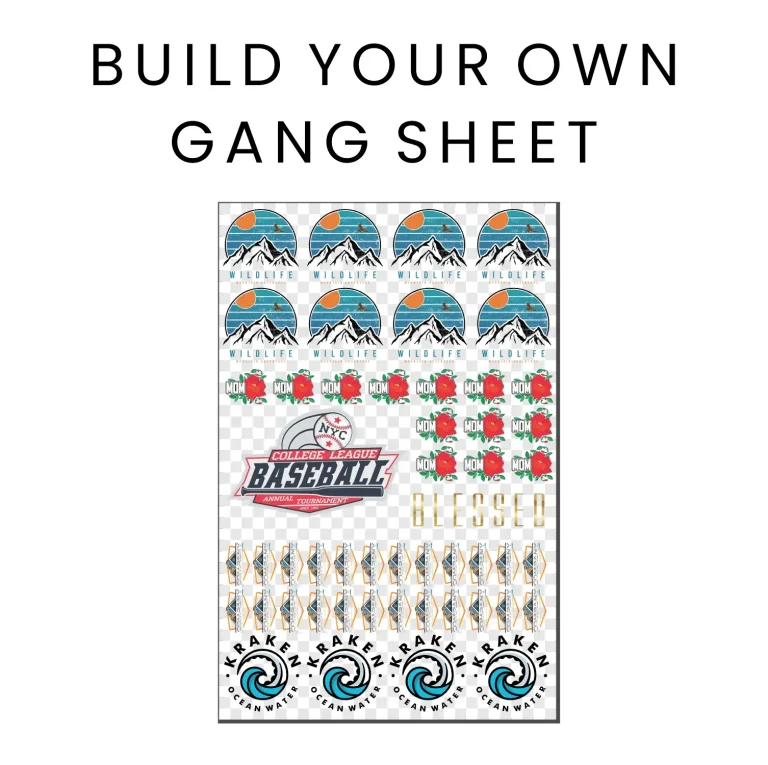

If you’re stepping into the realm of Direct-to-Film (DTF) printing, the DTF Gangsheet Builder is an essential tool that will elevate your fabric printing projects. This innovative builder allows you to efficiently arrange multiple designs on a single gangsheet, giving you the capability to maximize material usage while minimizing waste. In this guide, we will share valuable insights and DTF tips that cater specifically to beginners, ensuring you navigate the intricacies of gangsheet layout with ease. By leveraging the DTF Gangsheet Builder, you can enhance both the quality and efficiency of your printing techniques, making your designs come to life in vivid color and detail. Get ready to explore best practices that will transform your DTF printing experience and help you achieve professional results.

As you embark on your journey into the world of Direct-to-Film printing, utilizing the DTF Gangsheet Creator becomes pivotal for anyone seeking to streamline their design layout process. This sophisticated tool simplifies the assembly of multiple graphics into a cohesive gangsheet, effectively reducing material costs while maximizing output efficiency. Throughout this discussion, we will delve into foundational DTF printing principles, explore various print techniques, and offer practical advice tailored for newcomers to fabric printing. Understanding how to create an effective gangsheet layout will not only enhance your designs but also improve the overall business profitability. Let’s take a closer look at how you can optimize your workflow and produce stunning printed fabrics.

Introduction to DTF Printing

Direct-to-Film (DTF) printing has revolutionized the fabric printing landscape, providing users with innovative methods for creating high-quality designs. This printing technique enables the transfer of intricate graphics directly onto a variety of materials, making it a favored choice among those seeking vibrant and durable designs. As a beginner, understanding the fundamentals of DTF printing and how it works is essential for harnessing its full potential.

The unique aspect of DTF printing lies in its gangsheet layout, allowing multiple designs to be printed on a single film sheet. This efficiency not only saves costs but also streamlines the production process. As you embark on your DTF printing journey, familiarizing yourself with key concepts and techniques will set a solid foundation for future success.

Mastering the DTF Gangsheet Builder

The DTF Gangsheet Builder is an essential tool for anyone serious about optimizing their printing output. By allowing you to arrange multiple designs within a single sheet, it maximizes film usage and minimizes waste. Understanding how to effectively use this software can dramatically improve your workflow and enhance your production efficiency.

To get started with the DTF Gangsheet Builder, it is crucial to familiarize yourself with the software interface and layout options. This knowledge will empower you to create designs that are not only visually appealing but also printed efficiently. Utilizing features such as snap-to-grid and alignment tools can further streamline your process and ensure that your gang sheet layout is both professional and cost-effective.

Essential Materials for High-Quality DTF Printing

Selecting the right materials is pivotal for achieving vibrant and long-lasting prints in DTF printing. High-quality transfer films and DTF inks are essential for producing crisp designs and maintaining durability through numerous washes. Always opt for reputable brands that specialize in DTF printing to guarantee the quality of your output.

In addition to inks and films, the type of fabrics used in your projects also plays a significant role. Whether you’re working with cotton, polyester, or mixed blends, understanding how these materials interact with DTF inks will help you achieve superior results. Remember that the combination of quality materials and proper printer settings leads to the best printing outcomes.

Design Optimization for DTF Printing

Creating designs that are optimized for DTF printing is fundamental to the success of your projects. Utilizing high-resolution images, such as PNG or TIFF formats, ensures clarity and detail that translate beautifully onto fabric. Pay special attention to design elements to prevent pixelation and maintain quality.

In addition to file formats, managing size and placement of your designs on the gang sheet will maximize efficiency. Properly scaling your artwork not only enhances the visual impact but also decreases material waste. By carefully planning your layouts before finalizing designs, you set the stage for an excellent printing experience.

Testing and Refining Your DTF Layouts

Testing your layouts before executing a full print run is a critical step in the DTF printing process. Conducting test prints allows you to evaluate the arrangement of designs on your gang sheet and identify any necessary adjustments. This early phase can save resources and prevent costly mistakes later on.

Additionally, refining your layouts based on test print outcomes can lead to improved productivity and quality control. Consider factors such as color placement and spacing during this stage to ensure that your final prints mirror your creative vision, contributing to a polished final product.

Troubleshooting Common DTF Printing Issues

Like any printing process, DTF printing comes with its share of potential challenges. Common problems such as ink bleeding and poor adhesion can lead to disappointing results. To mitigate these issues, it’s important to conduct regular printer maintenance and ensure that you’re using quality films that enhance the transfer process.

When faced with difficulties, don’t hesitate to utilize available resources such as online communities and expert guidance. Engaging with experienced printers can offer valuable insights and solutions, helping you overcome specific challenges and refine your DTF printing techniques.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool designed for Direct-to-Film (DTF) printing that allows users to arrange multiple designs onto a single film sheet efficiently. By optimizing the gangsheet layout, users can maximize material use, reduce waste, and improve printing productivity.

What are the benefits of using DTF printing techniques with the Gangsheet Builder?

Utilizing DTF printing techniques with the Gangsheet Builder offers several benefits, including cost efficiency through reduced film usage, the ability to print multiple designs simultaneously, and enhanced print quality by ensuring colors are vibrant and well-adhered to fabrics.

What essential materials should I use for my DTF Gangsheet Builder projects?

For optimal results when using the DTF Gangsheet Builder, it’s crucial to use high-quality inks and transfer films. These materials contribute to vibrant color output and strong adherence to fabrics, essential for successful DTF printing.

What are some common DTF tips for beginners using the Gangsheet Builder?

Beginners using the DTF Gangsheet Builder should focus on high-resolution image formats, manage their design sizes effectively, and utilize dedicated software for optimal layout. Additionally, always perform test prints before the final production to catch any potential layout issues.

How can I troubleshoot common issues when using the DTF Gangsheet Builder?

Common issues in DTF printing can include poor adhesion or color inconsistency. To troubleshoot, regularly maintain your printer, adjust printer settings based on the ink type, and ensure high-quality films are used. Performing test prints can also reveal layout or design issues before full production.

What post-printing procedures are essential for DTF prints created with the Gangsheet Builder?

After printing with the DTF Gangsheet Builder, proper transfer methods, such as using a heat press, are essential for ensuring strong adhesion. Additionally, following specific curing techniques based on the ink type will ensure that prints maintain their quality and vibrancy over time.

| Key Points | Details |

|---|---|

| Introduction | Overview of DTF Gangsheet Builder and its significance in DTF printing. |

| Understanding DTF Basics | Importance of quality materials and correct printer settings for optimal results. |

| Design Optimization | Use high-resolution formats and manage design sizes carefully for clarity. |

| Layout Techniques | Efficiently arrange designs using software to minimize waste. |

| Post-Printing Procedures | Follow recommended transfer methods and curing techniques for durability. |

| Common Troubleshooting | Be prepared to identify and solve common DTF printing issues. |

Summary

DTF Gangsheet Builder is a revolutionary tool that can transform your approach to fabric printing. By mastering the techniques outlined in this guide, you’ll optimize your workflow, enhance the quality of your prints, and save on material costs. Begin your journey with DTF printing by focusing on high-quality materials, precise printer settings, and smart design practices. With these strategies, you’ll not only improve your outputs but also elevate your skills in the vibrant world of textile printing.