The DTF Gangsheet Builder is revolutionizing the way we approach custom printing, making it a game changer for both hobbyists and small businesses alike. This innovative tool allows users to create multiple DTF designs on a single sheet, optimizing resources and minimizing waste, which is essential in the realm of gangsheet printing. As more individuals turn to DTF printing for creating eye-catching apparel, mastering the DTF Gangsheet Builder becomes crucial for producing high-quality, vibrant prints that stand out in today’s competitive market. Whether you’re exploring how to DTF print for the first time or seeking expert printing tips for beginners, this guide will equip you with the essential knowledge to harness the full potential of DTF technology. Join us as we delve into the fundamentals of DTF printing and unveil key strategies for utilizing the DTF Gangsheet Builder effectively.

The advent of Direct-to-Film technology has opened exciting avenues in the printing world, especially through the use of gang sheets—large sheets that contain multiple designs ready for transfer. With gangsheet creation tools, enthusiasts can efficiently prepare a range of custom graphics for application onto fabrics, enhancing both creativity and efficiency in garment production. Understanding how to utilize this gangsheet printing technique can significantly benefit artists and businesses looking to streamline their design processes while achieving stunning results. By leveraging advanced DTF design strategies, users can explore innovative ways to enhance their printing endeavors, learning vital skills that will elevate their craftsmanship. This guide aims to provide you with the knowledge and guidance necessary to master these essential tools and techniques in the evolving landscape of textile printing.

Understanding DTF Printing Basics

Direct-to-Film (DTF) printing is revolutionizing the custom apparel industry by allowing creators to transfer vibrant, intricate designs onto various fabrics effortlessly. This method utilizes a specialized printer that prints pigment inks onto a film, which is then covered with a bonding powder and heated to transfer the design onto the garment. For beginners, familiarizing themselves with DTF printing basics is crucial as it sets the foundation for successful printing projects. Given the rising interest in personalized fashion, understanding DTF printing’s potential can greatly enhance creativity and output.

Moreover, DTF printing not only offers high-quality results but also flexibility in terms of garment choice. Unlike traditional methods, DTF allows users to print on a wide range of fabrics including cotton, polyester, and blends, thus catering to diverse fashion tastes. Aspiring printers should invest time in grasping the essential elements involved in the DTF process, such as printer settings and the importance of using high-quality films. Mastering these basics will demystify DTF printing and inspire confidence to explore advanced techniques.

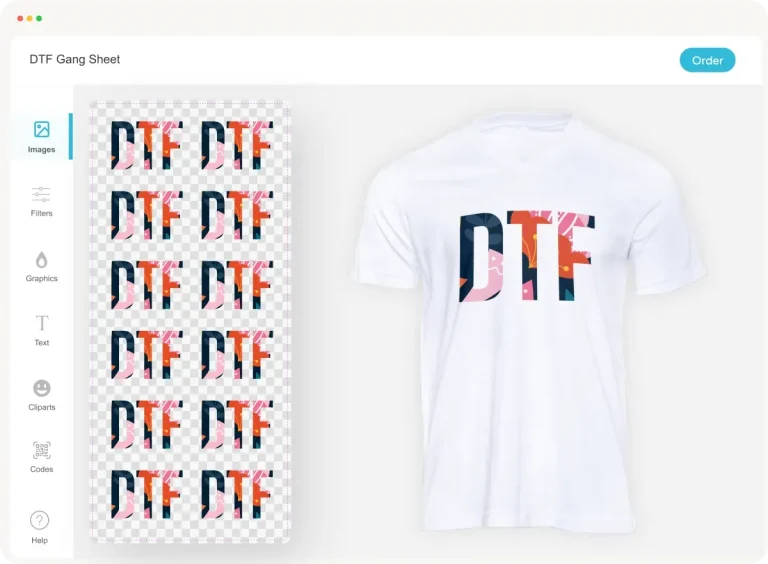

Exploring the DTF Gangsheet Builder

The DTF gangsheet builder is a game changer in the world of DTF printing, particularly for those looking to maximize their efficiency and minimize waste. A gangsheet involves arranging multiple designs on a single film, which not only optimizes material usage but also expedites the printing process, enabling users to produce various designs in one go. For beginners, this method not only saves money but also teaches them how to plan their layouts creatively to achieve the best results. Learning to effectively utilize a gangsheet can elevate a beginner’s DTF game by boosting productivity and reducing unnecessary resources.

When creating a gangsheet, organization is key. Beginners should be encouraged to experiment with different arrangements of their designs, taking into consideration spacing and size to ensure high-quality transfers. Additionally, understanding how to balance multiple designs on a single sheet can boost their learning process when exploring different printing techniques. With practice, beginner printers can refine their skills in managing design placement, and ultimately, create professional-looking prints that are visually compelling.

Essential Equipment for DTF Printing Success

Selecting the right equipment is fundamental to achieving success in DTF printing. A high-quality DTF printer, designed for vibrant colors and intricate designs, is paramount. Brands that specialize in DTF models provide technology geared towards achieving superior print quality. Other important components include the DTF film and hot-melt powder, both of which influence the final outcome of your prints. Beginners should research and invest in reputable brands to ensure their venture into DTF printing begins on a positive note.

In addition to the printer and films, tools such as heat presses and transfer sheets also play a critical role in the printing process. A reliable heat press with adjustable temperature and pressure controls can make a significant difference in how well prints adhere to fabrics. For first-time printers, understanding the functionalities of each piece of equipment will streamline their process, contribute to their learning curve, and ultimately enhance their ability to create high-quality prints consistently.

Mastering Design Software for DTF Printing

Proficiency in design software is essential for any beginner looking to create stunning DTF prints. Software like Adobe Photoshop and Illustrator offer powerful tools for layering images, adjusting colors, and ensuring high-resolution outputs—all vital aspects of DTF designs. Beginners should take the time to learn how to navigate these programs, focusing on important features that will enhance their design capabilities. Through tutorials and practice, they can develop the necessary skills to craft professional-grade prints.

Moreover, understanding design principles such as color modes and image formats significantly contributes to successful printing. For instance, designing in CMYK mode not only aligns with printing processes but also helps in achieving accurate color representation. Beginners should prioritize learning these principles, as they are foundational to producing exceptional DTF prints. By mastering design software, users can fully exploit their creative potential, making their printing projects both rewarding and successful.

Printing Process Tips for Beginners

The printing process in DTF can be daunting for beginners, but a few strategic tips can streamline it. Conducting test prints on smaller samples allows you to assess color accuracy and identify any issues before committing to larger runs. This practice not only helps in fine-tuning designs but also builds confidence in executing the printing process effectively. Additionally, layering designs wisely ensures that they adhere well and enhances the overall quality of prints.

It’s also critical to remain attentive to the specific settings required for each transfer, including temperature and time. Overheating can damage prints, while inadequately heating may lead to poor adhesion. Beginners should familiarize themselves with typical settings (like 305°F for approximately 10-15 seconds) and adapt based on the materials they are utilizing, ensuring optimal results. Following these tips will undoubtedly improve the quality of prints and the overall printing experience.

Post-Printing Inspection and Care for DTF Prints

Once the printing and transfer processes are complete, it’s crucial to take measures to ensure the longevity of your DTF prints. A thorough inspection of each print helps identify any defects or issues that may have arisen during the process. This proactive approach allows beginners to understand where improvements can be made for future prints, ensuring they consistently meet quality standards before distributing their products.

Additionally, providing users with proper care instructions is vital in preserving the integrity of DTF prints. Educating customers on how to wash and care for their garments—such as avoiding high heat and opting for gentle cycles—can significantly prolong the life of the prints. Emphasizing the importance of caring for prints to end-users not only reflects professionalism but also enhances customer satisfaction, contributing to repeat business.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool used in DTF printing that allows users to compile multiple designs on one film sheet. This method, known as gangsheet printing, maximizes efficiency by reducing material waste while enabling the simultaneous printing of various designs, making it ideal for custom apparel.

How can beginners get started with DTF printing using a Gangsheet Builder?

Beginners can start DTF printing by familiarizing themselves with design software like Adobe Photoshop or Illustrator to create their DTF designs. Once the designs are ready, users can employ the DTF Gangsheet Builder to organize and print their artwork on a single film, which streamlines the printing process and enhances productivity.

What are some essential printing tips for using a DTF Gangsheet Builder?

When using a DTF Gangsheet Builder, ensure to use high-resolution images and adhere to recommended temperature and pressure settings during the transfer process. Conducting test prints before large batches can help refine designs and avoid potential issues with color accuracy and adherence.

What equipment is necessary for effective DTF printing with a Gangsheet?

Essential equipment for effective DTF printing includes a high-quality DTF printer, suitable DTF films, and hot-melt transfer powder. Each piece of equipment plays a crucial role in achieving vibrant prints and ensuring successful design transfer onto garments.

Can you explain the benefits of using gangsheet printing in DTF designs?

Gangsheet printing significantly reduces production time and material waste by allowing multiple DTF designs to be printed on a single film sheet. This not only lowers costs but also improves efficiency, making it a popular choice for small businesses and hobbyists looking to maximize their output.

What are some common mistakes beginners make when using a DTF Gangsheet Builder?

Common mistakes include using low-resolution images, incorrect temperature and pressure settings during transfer, and neglecting to conduct test prints. Beginners should prioritize understanding the DTF printing process and equipment to prevent issues and achieve high-quality prints.

| Key Point | Details |

|---|---|

| Introduction to DTF Printing | DTF printing is popular for creating vibrant prints on various fabrics, essential for the custom apparel industry. |

| What is a DTF Gangsheet? | A printed sheet with multiple designs that reduces waste and enhances production efficiency. |

| Key Equipment for DTF Printing | 1. DTF Printer: High resolution and color accuracy are crucial. 2. DTF Film: Quality ensures vibrancy and adherence. 3. Transfer Powder: Reliable powder minimizes errors. |

| Getting Started with Design Software | Use software like Adobe Photoshop/Illustrator for creating layered designs with high-resolution images. |

| Tips for the Printing Process | Conduct test prints for color accuracy and pay attention to layering. |

| Mastering the Transfer Process | Set correct temperature (305°F – 320°F) and timing (10-15 seconds) for successful transfers. |

| Finalizing Your Prints | Provide care instructions and inspect final prints for quality before distribution. |

Summary

DTF Gangsheet Builder is an innovative approach for beginners interested in the dynamic world of DTF printing. This process allows for the efficient production of eye-catching prints that can be applied to various fabrics, making it a lucrative avenue for both artists and businesses. By focusing on crucial elements such as selecting the right equipment, mastering design software, and adhering to best printing practices, newcomers can unlock the potential of DTF printing. Whether you’re looking to create custom apparel or explore artistic endeavors, learning to utilize the DTF Gangsheet Builder effectively will set you on the path to creating stunning and vibrant prints.