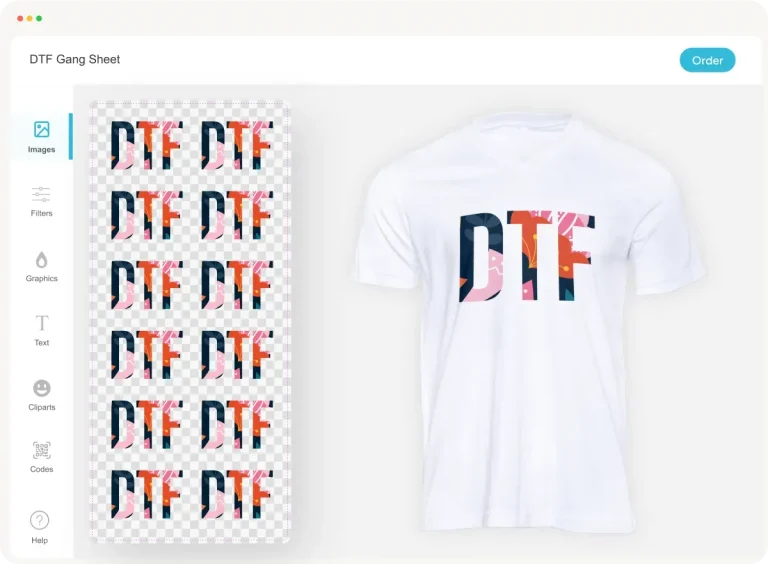

The DTF Gangsheet Builder has emerged as a game-changer in the textile and garment printing industry, revolutionizing how designs are produced compared to traditional printing methods. This innovative technology harnesses the power of Direct-to-Film (DTF) printing to deliver superior print quality, cost-effectiveness, and versatility when decorating garments. Unlike screen printing or direct-to-garment (DTG) techniques, the DTF Gangsheet Builder streamlines the process, reducing setup times and maximizing ink usage, making it an attractive option for businesses of all sizes. In this exploration, we will delve into the various benefits of the DTF Gangsheet Builder, including its outstanding efficiency, environmental sustainability, and adaptability across different fabric types. As we analyze its advantages over traditional methods, it becomes clear that the DTF Gangsheet Builder is not just a trend but a transformative approach to modern printing.

Embracing the future of textile printing, the Direct-to-Film Gangsheet technology is capturing the attention of businesses looking to enhance their printing capabilities. This approach stands out from conventional methods, such as screen or direct-to-garment printing, by offering a streamlined process that is not only efficient but also cost-effective. The innovative use of DTF sheets allows for intricate designs to be printed quickly, catering to small batch orders and diverse fabric applications. Additionally, this method reduces ink waste and labor costs typically associated with traditional production techniques. Ultimately, the DTF Gangsheet Builder represents a shift towards smarter, more adaptable printing solutions that meet the evolving demands of the market.

Comparing Print Quality Between DTF and Traditional Methods

When evaluating print quality, the DTF printing method, particularly through the DTF Gangsheet Builder, presents unparalleled clarity and vibrancy in its output. It excels in rendering intricate designs across diverse fabric types while ensuring color accuracy. Unlike traditional printing methods like screen printing that might require extensive setups for detailed designs, DTF’s advanced ink formulation facilitates superior blending and detail, allowing for a stunning finish that appeals to high-end clients.

Moreover, DTF printing can achieve a wider color gamut, leading to prints that are not only vibrant but also extraordinarily detailed. This capability stems from DTF’s unique printing process, which utilizes a specialized ink that adheres exceptionally well to various textiles. Screen printing, while reliable for many applications, often falls short with complex color schemes unless multiple screens are utilized, which can diminish overall quality and extend production times.

Cost Effectiveness of DTF Printing Solutions

Evaluating cost efficiency is crucial for any business looking to optimize its printing capabilities. DTF Gangsheet Builders offer an innovative solution that reduces setup time and ink costs significantly. Traditional methods, such as screen printing, require substantial initial investments for screens and labor-intensive manual setups, particularly for small batches or complex designs. In comparison, DTF allows for multiple designs to be printed on a single sheet, streamlining workflow and minimizing costs.

This adaptability in DTF technology not only enhances profitability but also democratizes access to high-quality printing for smaller businesses. The capacity to produce high-quality prints with minimal setup and less ink usage means that businesses can offer competitive pricing without sacrificing quality, thereby allowing them to tap into a broader market.

Production Speed: DTF vs. Traditional Printing

In the fast-paced world of garment production, speed can make or break a business. DTF printing, especially through the DTF Gangsheet Builder, provides a strategic advantage by vastly improving production timelines. The ability to print several designs simultaneously on one sheet minimizes labor costs and expedites the overall workflow, which is a significant departure from the traditionally slower methods of screen printing.

In contrast, traditional screen printing demands time-consuming setup procedures for each individual design, resulting in longer turnaround times. With DTF technology, businesses can respond quickly to market demands and capitalize on trends, enabling them to maintain a competitive edge in an ever-evolving industry.

User-Friendly Operation of DTF Gangsheet Technology

The usability of DTF printing technology marks a significant shift in the printing landscape. The DTF Gangsheet Builder is designed to be accessible, allowing easy operation even for novice users. Unlike traditional methods such as screen printing, which often necessitate extensive training and technical expertise, the DTF process is more straightforward and requires less manual intervention, making it ideal for small businesses and startups.

Furthermore, this user-friendly nature reduces the learning curve associated with adopting new printing technologies. As a result, businesses can quickly integrate DTF systems into their operations, allowing them to focus on growth and creativity rather than prolonged training and complex troubleshooting that comes with traditional equipment.

Exploring the Versatility of DTF Printing Solutions

One of the strongest advantages of DTF printing is its remarkable versatility. The DTF Gangsheet Builder can effectively handle a wide array of fabrics, from cotton to polyester blends, enabling businesses to cater to diverse customer needs without significant changes in equipment. This flexibility is a departure from traditional methods like screen printing, which often necessitates specialized setups for different fabric types.

Such versatility not only enhances service offerings but also allows businesses to pivot quickly to meet varying client demands, thereby increasing market reach. By minimizing the need for multiple printing systems to accommodate different projects, companies utilizing DTF technology can operate more efficiently, saving time, resources, and costs.

Environmental Considerations of DTF Printing Methods

As sustainability becomes increasingly vital to businesses, DTF printed products pose a more eco-friendly alternative to traditional printing techniques. The DTF Gangsheet Builder employs water-based inks, which typically result in fewer volatile organic compounds (VOCs) being released into the environment than those used in conventional screen printing. This characteristic appeals to brands aiming to reduce their ecological footprints and align with environmentally-conscious consumer values.

While traditional methods involve the use of solvent-based inks that can be detrimental to both health and environment, DTF’s cleaner approach makes it a preferred option for manufacturers focused on sustainability. Companies adopting DTF technology can promote their commitment to eco-friendly practices, potentially attracting a new demographic of consumers who prioritize green initiatives in their purchasing decisions.

Frequently Asked Questions

What are the main advantages of using a DTF Gangsheet Builder compared to traditional printing methods?

The DTF Gangsheet Builder offers several advantages over traditional printing methods like screen printing and direct-to-garment (DTG) printing, including superior print quality with vibrant colors and intricate details, cost efficiency for bulk orders, faster production speeds, ease of use for novice operators, and greater versatility across various fabric types.

How does the DTF Gangsheet Builder improve cost effectiveness in printing?

The DTF Gangsheet Builder improves cost effectiveness by allowing simultaneous printing of large designs, which significantly reduces setup and labor costs compared to traditional methods like screen printing. This is especially beneficial for businesses that handle smaller orders and complex designs, as it minimizes ink usage and streamlines the production process.

What is the ink usage comparison between DTF printing and traditional screen printing?

In terms of ink usage, DTF printing typically uses less ink than traditional screen printing, which often requires multiple layers and setups for complex designs. The DTF Gangsheet technology employs a unique ink formulation that allows for sharper detail and better color blending, making it a more efficient choice for garment decoration.

How does the DTF Gangsheet Builder contribute to faster production speeds?

The DTF Gangsheet Builder contributes to faster production speeds by enabling the printing of multiple designs on a single sheet simultaneously, which reduces the time spent on setups typical of traditional methods. This efficiency allows businesses to respond quickly to market demands and time-sensitive orders.

In what ways is DTF printing more versatile than traditional printing methods?

DTF printing is more versatile than traditional methods as it can be applied to a wide range of fabric types, including cotton, polyester blends, and more. This flexibility allows businesses to accommodate complex, multi-color designs without needing multiple machines, thereby enhancing their capability to serve diverse client demands.

What environmental benefits does the DTF Gangsheet Builder offer compared to traditional printing methods?

The DTF Gangsheet Builder offers several environmental benefits, primarily due to its use of water-based inks that emit fewer volatile organic compounds (VOCs) compared to conventional inks used in traditional screen printing. This makes DTF printing a more eco-friendly option, appealing to businesses that prioritize sustainability.

| Key Points | DTF Gangsheet Builder | Traditional Methods |

|---|---|---|

| Print Quality and Detail | Excels in vibrant colors and intricate details; better ink blending. | May require multiple screens; can limit print quality and increase labor costs. |

| Cost Efficiency | Allows for simultaneous printing of large designs; less ink usage. | High setup costs and labor-intensive processes hinder smaller orders. |

| Production Speed | Rapid printing on one sheet; improves turnaround times. | Time-consuming setup and prolonged print runs due to complexity. |

| Ease of Use | User-friendly for novices; easier to operate with less training needed. | Requires extensive training for effective operation. |

| Versatility | Applicable to various fabric types; handles multi-color designs efficiently. | Less adaptable; may require multiple systems for different fabrics. |

| Environmental Impact | More eco-friendly; uses water-based inks with fewer emissions. | May involve inks and emulsions that emit more volatile substances. |

Summary

The DTF Gangsheet Builder is transforming the landscape of garment decoration and printing industries. By providing superior print quality, cost effectiveness, faster production speed, ease of use, remarkable versatility, and reduced environmental impact, this innovative technology is appealing to modern businesses striving for excellence. As the shift towards Direct-to-Film printing becomes stronger, more companies are likely to embrace DTF solutions to achieve high-quality results while also meeting changing market demands. Understanding these benefits is crucial for any entrepreneur or business looking to stay competitive in the evolving textile printing sector.