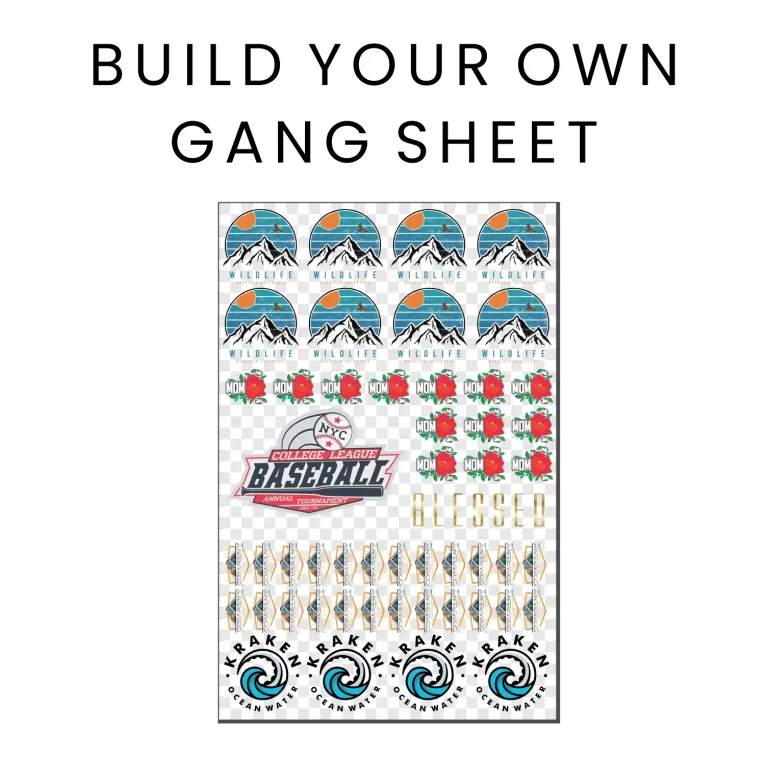

In the realm of custom apparel printing, the **DTF Gangsheet Builder** stands out as a game-changer for enthusiasts and professionals alike. This innovative tool revolutionizes the DTF (Direct to Film) printing process by enabling creators to efficiently layout multiple designs on a single sheet, maximizing their material usage without compromising on quality. As we delve into the nuances of DTF printing techniques, you will discover how to leverage the DTF Gangsheet Builder for producing high-quality DTF transfers that captivate audiences. Additionally, we will explore essential DTF design optimization strategies and helpful DTF software tips to elevate your printing projects. Prepare to transform your approach to custom apparel with insights that will help you produce stunning, vibrant transfers every time.

Entering the exciting world of custom clothing production, the term **DTF Gangsheet Builder** represents an essential software solution that enhances the efficiency of Direct to Film printing methods. This tool is invaluable for anyone seeking to streamline their workflow while ensuring the creation of stunning transfers. By utilizing effective gang sheet techniques and focusing on design optimization, users can unlock the full potential of their printing ventures. Furthermore, various tips for software utilization help navigate the intricacies of DTF applications, ensuring both novice and expert users produce vibrant and high-quality results. Embrace the possibilities offered by DTF technology as you navigate the landscape of custom apparel.

Understanding DTF Printing Techniques

DTF printing has become one of the most sought-after methods for custom apparel production due to its ability to produce vibrant and detailed designs. This technique allows colors to be printed directly onto a special film, which is then transferred onto fabric using heat and pressure. One of the key advantages of DTF printing is its versatility; it can be applied to a variety of materials, making it a favorite among apparel designers and businesses. To fully harness the potential of DTF printing, understanding the various techniques involved, such as adjusting ink saturation and utilizing the right heat settings, is crucial.

Moreover, mastering DTF printing techniques involves a familiarity with different inks and films available in the market. Various formulations provide different effects, such as matte and glossy finishes. Furthermore, integrating high-quality DTF transfers into your workflow requires efficient design preparation and print execution to ensure that each transfer reproduces top-notch colors and details. Staying informed on the latest advancements in DTF technology can give your business a competitive edge as the industry continues to evolve.

Maximizing Efficiency with the DTF Gangsheet Builder

The DTF Gangsheet Builder is an indispensable tool for anyone serious about optimizing their custom apparel printing process. By enabling the arrangement of multiple designs on a single sheet, the Gangsheet Builder helps reduce material waste and simplifies printing logistics. Not only does it streamline the workflow, but it also allows businesses to process larger orders more efficiently. Understanding the functionalities of this software will enhance your production capabilities and boost overall output.

When using the DTF Gangsheet Builder, consider how you can organize designs based on order size. Smaller designs can be positioned closely together, which not only maximizes space but also minimizes production costs. Additionally, refining your layouts with this builder means less time spent on adjustments during actual printing, paving the way for a smoother production run. As you become proficient in utilizing the Gangsheet Builder, you’ll notice significant improvements in both efficiency and cost-effectiveness.

Mastering Color Management for Superior Results

Effective color management is vital in DTF printing, where the goal is to achieve vibrant and accurate replicated colors on fabric. DTF printing requires a keen understanding of how color profiles work within different software and printer settings. By properly calibrating your prints to match the CMYK color model, you can avoid discrepancies between the designed and final printed product. Additionally, setting up accurate color profiles can help maintain consistency across multiple prints, ensuring your product meets customer expectations every time.

To further enhance your color management, it’s essential to perform test prints regularly. Small adjustments can make a significant difference, so be sure to monitor how colors change when printed on different materials. Implementing proper color management techniques not only enhances print accuracy but also increases customer satisfaction, ultimately leading to a more successful custom apparel business.

Design Optimization Tips for Better Transfers

To achieve the best results from your DTF printing process, effective design optimization is crucial. Users should leverage the capabilities of the DTF Gangsheet Builder to enhance layouts for superior transfers. This involves strategically arranging designs, ensuring that they are sized and spaced appropriately to maximize the use of the printing sheet while still maintaining a visually appealing aesthetic. By focusing on these aspects, you can minimize wasted material and drive cost efficiencies.

Further, employing smart organization tactics, such as grouping designs by style or color palette, can help streamline the printing process. This method not only optimizes resources but also facilitates a quick production turnaround. Remember to keep in mind the sizing of the final garment prints, ensuring that all designs fit seamlessly without distortion. By mastering design optimization, you can significantly enhance the quality and appeal of your printed apparel.

Importance of Testing and Calibration in DTF Printing

Before launching into a full-scale production run, thorough testing and calibration of your DTF printing setup are essential. By conducting test prints, you can identify any issues with color accuracy and transfer adhesion, as well as adjust heat press temperatures and timing accordingly. This step is critical in ensuring that the final products meet high-quality standards and are durable enough for customer wear.

Moreover, regular calibration of your DTF setup ensures consistent output and can help avoid potential setbacks during actual production runs. Engage in practices such as wash tests to verify the durability of the transfers. By committing to thorough testing and calibration, you’re investing in the long-term success of your custom printing endeavors.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is specialized software that helps users create and organize multiple designs on a single sheet for DTF printing. By maximizing material usage and increasing printing efficiency, it enables the production of high-quality DTF transfers with vibrant colors.

What software options are best for optimizing DTF Gangsheet Builder performance?

For optimal use of the DTF Gangsheet Builder, consider using Adobe Illustrator for vector graphics and layout, along with specific DTF print software that offers user-friendly interfaces and tailored features for gang sheet creation.

How can I ensure effective color management in DTF printing with the Gangsheet Builder?

To achieve stunning prints using the DTF Gangsheet Builder, verify color profiles between your design software and printer. Use CMYK format for designs and always conduct test prints to adjust colors accurately before finalizing your prints.

What design optimization techniques can I apply when using the DTF Gangsheet Builder?

When using the DTF Gangsheet Builder, maximize your design layout by closely arranging designs to minimize white space and grouping elements by size. This ensures efficient use of the gang sheet and better fit on garments.

Why is testing and calibration important in DTF printing with the Gangsheet Builder?

Testing and calibration are crucial before a full production run with the DTF Gangsheet Builder. Conducting test prints and wash tests ensures optimal transfer quality and durability, preventing common issues during actual production.

How can I stay updated with the latest DTF printing techniques related to the Gangsheet Builder?

To stay informed about the latest DTF printing techniques and innovations for the Gangsheet Builder, engage with online communities, follow industry blogs like Printavo, and watch tutorials on platforms like YouTube.

| Key Topic | Details |

|---|---|

| Introduction to DTF Gangsheet Builder | A tool to maximize material use and improve production efficiency for high-quality custom apparel transfers. |

| Understanding Software Utilization | Familiarity with DTF software (e.g., Adobe Illustrator) for creating designs is crucial. |

| Mastering Color Management | Proper color settings are essential for vibrant prints; use CMYK and verify profiles. |

| Design Optimization Tips | Arrange designs closely to maximize coverage and minimize waste. |

| Importance of Testing and Calibration | Conduct test prints and wash tests to ensure transfer quality and durability. |

| Engaging with Community Learning | Join forums and social media groups for shared insights and learning. |

| Staying Updated with Innovations | Keep abreast of the latest DTF technologies and tutorials for improved techniques. |

Summary

The DTF Gangsheet Builder is essential for creating high-quality transfers in the world of custom apparel printing. By mastering this tool, you can enhance your design workflows, optimize material use, and ensure vibrant colors in your prints. Understanding how to effectively utilize software, manage colors, test your processes, and engage with the community are vital components for success. As you continue to adapt to the latest innovations in DTF printing, your expertise in the DTF Gangsheet Builder will set you apart in a competitive market.