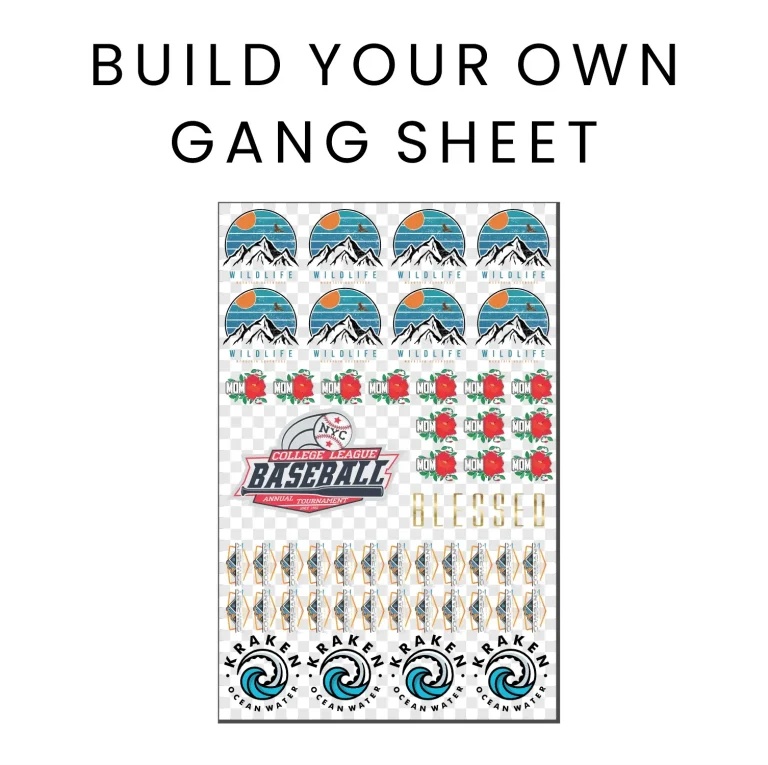

The DTF Gangsheet Builder is revolutionizing the way creative individuals and print shops approach Direct-to-Film (DTF) printing. This innovative tool streamlines the gangsheet printing process, allowing you to efficiently arrange multiple designs on a single sheet for high-quality heat transfer printing. With its user-friendly interface, the DTF Gangsheet Builder maximizes ink usage while minimizing waste, making it an essential resource for print design enthusiasts. As DTF printing gains traction, mastering the DTF Gangsheet Builder will undoubtedly enhance your print projects, ensuring vibrant colors and intricate details that can transform any fabric. Whether you’re in fashion, home decor, or promotional materials, this powerful tool is your gateway to professional-grade prints.

Introducing the DTF Gangsheet Builder, a cutting-edge solution that simplifies the Direct-to-Film printing process. This exceptional tool is designed for gangsheet printing, allowing users to efficiently combine various print designs onto one sheet, optimizing material usage and reducing costs. DTF printing, known for its ability to create stunning, long-lasting designs through heat transfer printing, is becoming increasingly popular among artisans and commercial printers alike. By harnessing the capabilities of the Gangsheet Builder, you can ensure that each detail of your print design is captured with precision. This guide will explore effective techniques and tips to help you use this powerful software to elevate your printing projects.

Exploring the Advantages of DTF Printing

DTF printing has revolutionized the way we think about heat transfer technologies, offering a dynamic and versatile option for printing on a variety of fabrics. Unlike traditional methods, DTF allows for a wider range of material compatibility including cotton, polyester, and blends, ensuring that creators can expand their product offerings. This flexibility not only caters to personal preferences but also enhances marketability, allowing businesses to tap into lucrative niches like custom apparel or promotional merchandise that require high-resolution printing.

Furthermore, DTF printing is increasingly recognized for its cost-effectiveness. By utilizing gangsheet printing, multiple designs can be printed simultaneously, which reduces ink usage and material waste significantly. This not only lowers production costs but also promotes a more environmentally friendly approach to manufacturing since less material is discarded in the process.

Getting Started with the DTF Gangsheet Builder

The DTF Gangsheet Builder is an essential tool for those looking to optimize their printing workflow. Setting up this software appropriately is crucial for maximizing productivity and achieving quality output. Popular graphic design software like Adobe Illustrator or Photoshop seamlessly integrates with the Gangsheet Builder, enabling users to arrange their designs with precision. As you start using the DTF Gangsheet Builder, familiarizing yourself with its specific functionalities will enhance your layout efficiency and overall design creativity.

Once the DTF Gangsheet Builder is activated, the focus shifts to the design process. Utilizing templates can streamline the setup, as they are designed to prevent overlap and ensure adequate spacing. This degree of organization is invaluable, particularly for high-volume prints where time efficiency is paramount. By mastering the layout features of the Gangsheet Builder, you can create intricate designs that stand out while being cost-effective.

Mastering Design Placement Techniques

Effective design placement is key when using the DTF Gangsheet Builder as it directly impacts the final print quality. Avoiding overlaps and ensuring proper margins will optimize the use of space on the film, which is particularly important in gangsheet printing where multiple designs are printed on a single sheet. By strategically placing designs on the gang sheet, you can minimize wasted material and maximize the number of successful transfers.

Additionally, balancing the visual elements of each design is vital for creating an appealing gangsheet. A well-organized layout that combines graphics with text not only enhances the overall visual impact but also ensures that each design remains readable and highlights its intended message. Utilizing design tools and software features effectively will allow you to play with scale, positioning, and even color schemes to achieve eye-catching layouts.

Optimizing Your Printer Settings for DTF

Once your design is finalized on the DTF Gangsheet Builder, ensuring that printer settings align with the material and ink specifications is crucial for achieving high-quality prints. Selecting the correct media type is essential; many printers offer specific settings tailored for DTF media that promote optimal ink application and adherence to the transfer film. This attention to detail contributes to the clarity and vibrancy of the final product.

Moreover, setting the printer to high-resolution settings is equally important, as this determines the detail and fidelity of the prints. A well-calibrated printer paired with properly configured settings can make a significant difference in the quality of heat transfer printing. Engaging with community profiles to share settings and experiences can lead to even better-printer performance and, ultimately, superior print results.

Executing the Printing Process

The printing process for a DTF gangsheet involves careful execution to ensure all elements come together successfully. Conducting test prints is paramount before launching into a larger production run, as these initial tests help identify any discrepancies in alignment or color accuracy. This step allows for necessary adjustments to be made without incurring significant material costs.

Moreover, it is beneficial to refer to vendor instructions frequently. Many DTF printers are accompanied by specialized software that offers troubleshooting guides and tips tailored for effective printing. Familiarizing oneself with these resources can save time and enhance the printing experience, leading to consistently high-quality outputs.

Effective Transfer Techniques for DTF Printing

The transfer process is one of the most critical stages in DTF printing and requires the right techniques to achieve a durable finish. Utilizing a heat press that is set to a consistent temperature is essential; typical settings hover around 370°F, with a pressing duration of approximately 15 seconds. These specifications are crucial for ensuring the ink bonds adequately to the fabric, providing long-lasting results.

Additionally, allowing the fabric to cool down before peeling off the backing material is a critical step often overlooked. This cooling period is essential for the transfer to set correctly, which prevents damage to the print and ensures that the design adheres optimally to the substrate. Resources such as educational articles and comprehensive guides on renowned platforms can offer valuable insights into mastering these techniques.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work in DTF printing?

The DTF Gangsheet Builder is a tool used in Direct-to-Film (DTF) printing that enables users to arrange multiple designs on a single film sheet efficiently. This method optimizes ink usage and reduces costs by printing several designs at once, making it a game-changer for both professional print shops and DIY creators.

What are the key benefits of using the DTF Gangsheet Builder for print design?

Using the DTF Gangsheet Builder allows for versatile and high-quality prints on various fabrics such as cotton and polyester. The gangsheet method not only minimizes waste but also improves production efficiency, ensuring vibrant colors and intricate designs—all at a lower cost compared to traditional heat transfer printing methods.

How can I set up my software to use the DTF Gangsheet Builder effectively?

To set up your software for the DTF Gangsheet Builder, choose graphic design software that supports gangsheet layouts, such as Adobe Photoshop or Illustrator. Follow online tutorials to learn about arranging multiple designs correctly on a single sheet, ensuring optimal printing results.

What printer settings should I configure when using the DTF Gangsheet Builder?

When preparing to print using the DTF Gangsheet Builder, configure your printer settings by selecting the right media type and optimizing the resolution. It’s essential to use settings specifically designed for DTF printing to achieve the best results and maintain color accuracy.

What steps should I take to ensure successful printing with the DTF Gangsheet Builder?

To ensure successful printing with the DTF Gangsheet Builder, start with test prints to check for color alignment and discrepancies. Use high-resolution settings and adhere to vendor instructions for the DTF printer, which often include tips for avoiding common issues.

What post-transfer care is necessary after using the DTF Gangsheet Builder?

After transferring prints using the DTF Gangsheet Builder, allow the fabric to cool completely before peeling off the backing. Follow garment care instructions carefully to enhance the longevity of your DTF prints, ensuring they remain vibrant and durable through proper washing techniques.

| Key Point | Details |

|---|---|

| Understanding DTF Printing | Involves printing designs onto special film and transferring to fabric. Allows vibrant colors and intricate details. |

| Benefits of DTF Printing | Versatile, high-quality, and cost-effective due to gang sheets. |

| Setting Up Software | Compatible graphic software (Photoshop, Illustrator) is essential for layout. |

| Design Placement | Careful arrangement prevents overlaps and maximizes gangsheet usage. |

| Adjusting Printer Settings | Configure media type and resolution for optimal printing. |

| Printing the Gangsheet | Conduct test prints to ensure alignment and color accuracy. |

| Transferring to Fabric | Use correct heat press settings for transfer success. |

| Finishing Touches | Check prints and follow care instructions for longevity. |

Summary

DTF Gangsheet Builder is an essential tool for creators looking to streamline their DTF printing process effectively. This guide covers every step from understanding DTF basics to transferring designs onto fabric, ensuring you maximize the potential of your garments. By utilizing the gangsheet method, you not only save on ink and material costs but also optimize production efficiency. Keeping up with best practices and community resources will enhance your skills and help you produce high-quality, vibrant prints suitable for any application. Embrace the versatility and cost-effectiveness of DTF printing with the DTF Gangsheet Builder!