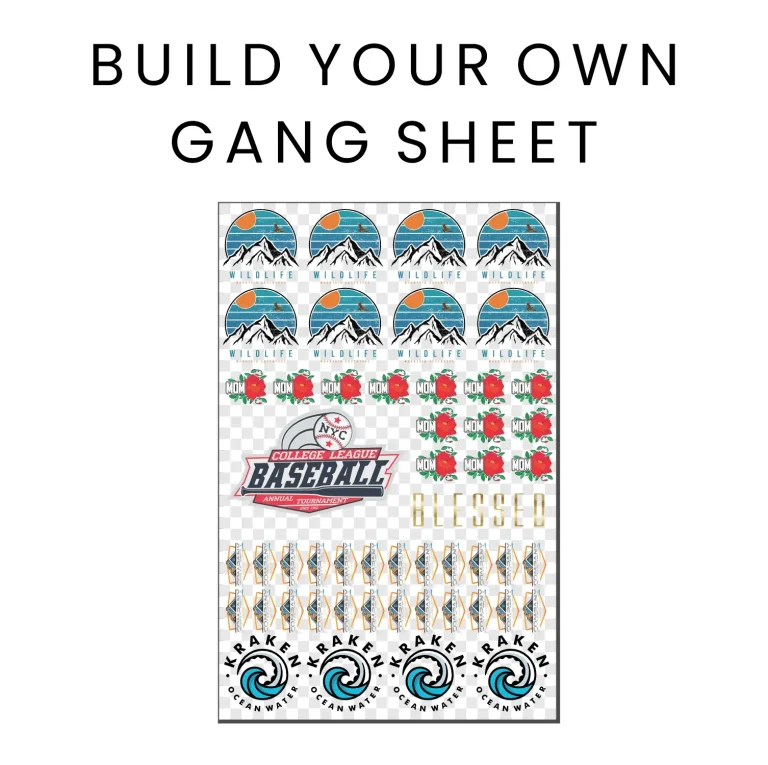

In the dynamic landscape of modern printing, the **DTF Gangsheet Builder** emerges as a game-changer for fabric printing enthusiasts. This innovative tool harnesses the power of Direct-to-Film (DTF) printing, allowing users to maximize efficiency while minimizing material waste. With the right DTF printing tips and a deep understanding of effective DTF application techniques, printers can elevate their craft and achieve stunning results. The DTF Gangsheet Builder not only simplifies the organization of artwork but also enhances productivity for bulk orders, making it an essential asset for any serious printer. Join us as we delve deeper into the functionalities of the DTF Gangsheet Builder and uncover valuable techniques that can transform your printing process.

Direct-to-Film printing, commonly referred to as DTF printing, has revolutionized the garment decoration industry with its remarkable ability to produce intricate designs. The **Gangsheet printing** method, integrated into the DTF process, allows multiple designs to be printed on a single sheet, optimizing both time and resources. By exploring various DTF printing techniques, users not only enhance their production capacities but also unlock the potential for vibrant and colorful outputs. With tools like the DTF Gangsheet Builder, mastering these techniques has become more accessible, enabling both novice and seasoned printers to excel. Let’s explore how these innovative processes can breathe new life into your printing projects.

Essential DTF Printing Tips for Beginners

When diving into DTF printing, it’s essential to equip yourself with foundational tips that can significantly impact the success of your projects. Start by understanding that the quality of your film and inks are paramount. Low-quality substrates can lead to poor adhesion and color accuracy, which can undermine even the most well-designed artwork. To ensure that you are using the best materials, invest in well-reviewed DTF inks and films that are known to deliver vibrant prints and reliable performance. Make it a habit to regularly check for updates or feedback on these materials, as advancements in technology may introduce new options that can enhance your results.

Another key tip is to familiarize yourself with your printer’s capabilities. Each DTF printer has unique settings that can influence the final print quality, from resolution to ink saturation. Conducting test prints with various settings can help you find the optimal balance that produces the best colors and details without sacrificing speed. Pay close attention to the printer profiles and ensure you are using the most suitable one for DTF purposes, as this can mean the difference between a mediocre output and a stunning, eye-catching print.

The Role of DTF Gangsheet Builder in Cost Efficiency

Utilizing the DTF Gangsheet Builder can drastically improve your production efficiency, particularly when it comes to minimizing costs associated with printing. By arranging multiple designs on a single film sheet, you not only maximize the use of your materials but also reduce waste. For businesses that often deal with bulk orders, this feature is incredibly valuable. It allows you to create a diverse range of products within a single print run, saving both time and money in the process. As a result, understanding how to utilize the Gangsheet Builder effectively can position your business for improved profitability.

Moreover, the ease of use offered by the DTF Gangsheet Builder allows for better organization of complex projects. By being able to strategically place your designs, you can ensure that every inch of the film sheet is utilized efficiently. This arrangement not only aids in cost-effectiveness but also helps streamline the production workflow. For companies looking to thrive in the highly competitive custom printing market, mastering the Gangsheet Builder can provide a significant edge over competitors who may still be relying on less efficient methods.

Understanding DTF Printing Techniques for Quality Artworks

To create high-quality prints using DTF technology, mastering various DTF printing techniques is crucial. Techniques such as pre-treatment and color separation can improve the vibrancy and adherence of your printed designs. Pre-treating your fabric ensures that the ink bonds effectively with the material, leading to longer-lasting and more vibrant results. This process involves applying a special solution that makes the fabric receptive to the inks used in DTF printing, and understanding how and when to apply this treatment can elevate your print outcomes significantly.

The color separation technique is also essential, especially when dealing with complex designs or a broad color palette. Knowing how to properly separate your colors can help ensure that your prints maintain clarity and avoid unwanted blending during heat transfer. Many DTF artists use software that specializes in color separations specifically for printing. Thus, utilizing the right techniques and tools not only enhances the final product but also fosters growth in your skills as a DTF printer.

Tips for Balancing Print Speed and Quality in DTF

In the fast-paced world of custom garment printing, finding the balance between speed and quality is essential. While it might be tempting to increase print speed to meet tight deadlines or high-volume orders, this can often lead to sacrifices in detail and vibrancy. One effective approach is to assess the complexity of your designs before deciding on your speed settings. Complex designs may require slower speeds to ensure that fine details are captured properly, while simpler designs could potentially be printed at higher speeds without a significant loss in quality.

Regular maintenance of your DTF printer is also vital when striving for an optimal balance. Ensure that print heads are clean and that your printer is calibrated correctly. A well-maintained machine can operate at higher speeds without compromising the final print quality, allowing you to fulfill orders more efficiently. Additionally, investing in high-quality inks and film can positively impact your print results, even at faster speeds. Taking these steps will not only improve your workflow but also increase customer satisfaction with the final product.

DTF Application Techniques for Maximum Adhesion

The success of a DTF print can heavily rely on your application techniques. The heat transfer process involves not just the right temperature but also the appropriate pressure and duration per fabric type. Varied materials can react differently under heat, which makes it crucial to adjust your heat press settings accordingly. For instance, delicate fabrics may require lower temperatures and shorter application times to prevent damage, while thicker materials might need more time and higher temperatures for a solid bond.

Moreover, experimenting with different press times can yield significant improvements in adhesion quality. Each design can have different needs, and conducting small test runs allows you to determine the best combination of pressure and time for achieving optimal results. This experimentation phase is crucial, especially when adapting techniques for new fabrics or intricate designs. By honing your application techniques, you can ensure that your DTF prints not only look great but also withstand regular wear and washing.

Engaging with the DTF Printing Community for Continuous Learning

Engaging with the DTF printing community is an invaluable resource for learning and sharing knowledge. Online forums, social media groups, and industry-specific events provide platforms where both novices and seasoned professionals can discuss their experiences, tips, and troubleshoot common issues. Being active in these communities fosters a culture of collaboration, where sharing insights about DTF application techniques or printer tweaks can lead to collective improvement and innovation in designs and workflows.

Participating in community discussions also opens up opportunities for attendees to learn about emerging trends in DTF printing technology and sustainable practices. As the industry continues to evolve, staying informed through active engagement can enhance one’s skills and adaptability in a competitive market. Plus, many experienced practitioners often share valuable resources such as tutorials, webinars, and workshops that can further enhance learning and implementation of DTF printing practices.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a specialized software that allows users to organize and arrange multiple designs on a single film sheet for Direct-to-Film (DTF) printing. It enhances DTF printing by optimizing layout efficiency, minimizing material waste, and simplifying the process of creating gang sheets, allowing for quicker production runs.

What are essential DTF printing tips for optimizing designs using the DTF Gangsheet Builder?

When using the DTF Gangsheet Builder, essential tips include familiarizing yourself with the software interface, optimizing your layout to minimize unused areas, and keeping track of print settings for each design. This ensures that you maximize your outputs while maintaining print quality.

How can I improve color accuracy in my DTF printing with the Gangsheet Builder?

To improve color accuracy in your DTF printing, use consistent printer profiles tailored for DTF technology, conduct thorough test prints to verify color output, and ensure all materials used are compatible. Proper color calibration is key for vibrant results on fabrics.

What role does heat press application play in DTF printing with the Gangsheet Builder?

Heat press application is crucial in DTF printing as it determines how well the transfer adheres to the fabric. Variables like temperature, pressure, and press time must be adjusted based on the specific fabric and design requirements to achieve optimal adhesion and durability.

Can you share some DTF application techniques for better results?

Some effective DTF application techniques include adjusting heat press settings according to the fabric type, testing different press times for each design, and ensuring the temperature is uniform across the pressing area. This will help ensure high-quality transfers.

How can I engage with others to improve my skills in using the DTF Gangsheet Builder?

Engaging with the community is invaluable for improving your DTF printing skills. Join online forums or social media groups focused on DTF printing, participate in discussions, and watch video tutorials on platforms like YouTube to learn from experienced users and stay updated on best practices.

| Key Topic | Description |

|---|---|

| DTF Printing | A modern printing method allowing designs to be directly printed on special film for heat transfer to fabrics. |

| Gangsheet Printing | Efficiently arranges multiple designs on a single film sheet to minimize waste and save costs. |

| DTF Gangsheet Builder | An intuitive software for organizing artwork and optimizing design layouts for DTF printing. |

| Color Calibration | Important for ensuring accurate color output through consistent printer profiles and test prints. |

| Print Speed vs. Quality | Finding the right balance between speed and print detail by adjusting settings and maintaining equipment. |

| Application Techniques | Involves proper heat press settings and timing to ensure optimal adhesion of prints. |

| Community Engagement | Joining online forums and discussing tips and techniques with other users for continuous learning. |

| Emerging Trends | Sustainability in printing is gaining focus, with eco-friendly options available. |

Summary

DTF Gangsheet Builder is a game-changer in the printing industry, allowing users to master the art of printing with efficiency and creativity. By leveraging the insights shared in this guide, users can enhance their understanding of DTF printing, optimize the utilization of the Gangsheet Builder, and stay connected with the vibrant printing community. As trends evolve and new techniques emerge, keeping abreast of these developments will ensure that your printing projects remain competitive and spectacular. Dive into the world of DTF printing with confidence, and watch your designs come to life vibrantly!