The DTF Gangsheet Builder is transforming the landscape of custom printing, providing an effortless way to optimize the direct-to-film printing process. With its capability to print multiple designs onto a single sheet, this innovative tool enhances print efficiency and minimizes material waste. Users can maximize their workflow by strategically arranging designs, ensuring that every inch of the sheet is utilized effectively. As sustainability becomes increasingly important, leveraging eco-friendly printing practices with the DTF Gangsheet Builder paves the way for a greener approach to custom apparel production. Moreover, careful management of heat press settings is crucial for achieving high-quality results that stand the test of time.

In the realm of custom apparel production, the evolution of design transfer printing techniques has led to the emergence of tools such as the DTF Gangsheet Builder. This cutting-edge software simplifies the process by allowing users to compile various illustrations efficiently onto one sheet, thus enhancing print capabilities. As direct-to-film technology gains traction, understanding essential print efficiency tips and how to manage heat press applications becomes vital for achieving superior results. Utilizing advanced design layout software facilitates organized and accessible arrangements of designs, setting the foundation for high-quality outputs. Ultimately, embracing eco-friendly printing methods aligns with modern consumer preferences, making this approach not only innovative but also responsible.

Understanding Direct-to-Film Printing (DTF)

Direct-to-Film (DTF) printing is rapidly becoming a preferred method for custom fabric designs, thanks to its exceptional ability to deliver vibrant results. This technique involves printing designs onto specialized transfer films that can easily be heat-pressed onto various fabric materials. The main advantage of DTF printing lies in its ability to achieve high-definition output with a variety of colors and intricate details that are often challenging to replicate with traditional printing methods. Additionally, the prints are known for their durability, offering resistance to fading and cracking, making them ideal for apparel and merchandise.

One of the standout features of DTF printing is its versatility. This method allows for more diverse applications, from garments to home textiles, thus enabling businesses to expand their product offerings. As trends evolve and consumers seek unique designs, DTF printing provides a solution that meets the growing demand for high-quality, customized prints. The integration of tools like the DTF Gangsheet Builder further enhances this process by optimizing layout and reducing material waste, further solidifying DTF printing’s status as a game-changer in the printing industry.

Maximizing Efficiency with DTF Gangsheet Builder

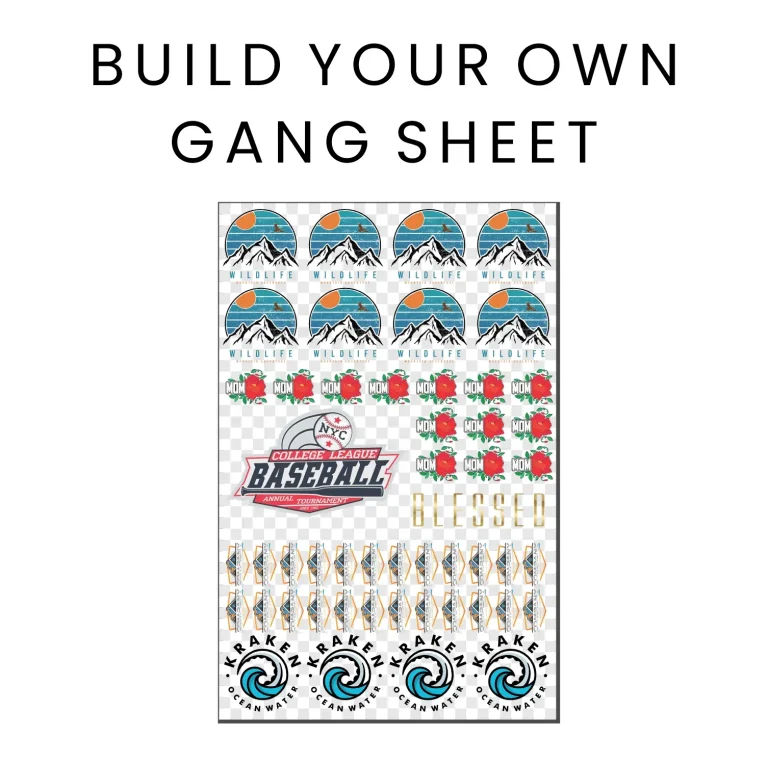

The DTF Gangsheet Builder is a transformative tool that significantly enhances printing efficiency. By enabling the arrangement of multiple designs on a single sheet, users can minimize wasted space and resources, making the printing process more economical. This capability not only cuts down on ink and material waste but also speeds up production time, allowing businesses to fulfill larger orders more swiftly. Incorporating smart layout strategies enhances the logistics of the printing process, ensuring that every inch of the film is utilized effectively.

In addition to its economic advantages, the DTF Gangsheet Builder supports better workflow management. Users can create a batch of designs for various clients or product lines at once, simplifying the process of preparing for large production runs. With effective organization and planning features, the Builder allows for quick adjustments to designs, making it easy to test new products or styles without compromising the overall efficiency of the operation.

Essential Print Efficiency Tips for DTF

To optimize print efficiency with DTF printing, several strategies can vastly improve results. One of the foremost tips is to maintain a clean and calibrated printing environment. Dust and debris can affect print quality and operation efficiency, while proper calibration ensures that colors and details are accurately rendered. Furthermore, regular cleaning of the printer heads and alignment checks can prevent common issues that lead to wasted material and time.

Additionally, employing color management practices is vital. Understanding color profiles and making necessary adjustments before printing can prevent costly errors. Invest in high-resolution images and be diligent about file preparation; ensuring that images are at least 300 DPI will enhance the quality of the final product. Coupled with consistent testing of heat press settings, these practices help achieve superior prints that elevate customer satisfaction and reduce complaints.

Crucial Heat Press Settings for Optimal Results

Configuring the right heat press settings is critical for the success of DTF printing. Each fabric type requires a specific heat and pressure setting; failing to adjust these can result in poor adhesion of the print. For example, lightweight fabrics might require less heat than heavier materials. It’s important to conduct initial tests with various types and thicknesses of fabric to determine the optimal settings that will ensure proper transfer and durability of the design.

In addition, understanding the importance of time in relation to temperature is essential. Too little time under heat may lead to poor adhesion, while too much can damage the fabric. Utilizing a heat press with programmable settings can significantly simplify this process, as it allows the user to set precise temperature, time, and pressure for different fabric types, ensuring reliable and repeatable results.

Software Tools for Enhanced DTF Design

The use of advanced design layout software is instrumental in enhancing the DTF printing process. Programs specifically designed for printed transfers enable users to arrange multiple designs with precision. These tools often come with features that automate design placement, providing an edge in optimizing the layout before printing. This not only expedites the design phase but also minimizes layout errors that can lead to material wastage.

Moreover, software that supports DTF printing often facilitates better control over color settings and image resolution. By having robust editing capabilities, users can enhance their designs with features like filtering, layer management, and color adjustments, ensuring that every print meets high artistic standards. Thus, leveraging the specialized capabilities of design software can greatly improve both efficiency and output quality in DTF printing.

Eco-Friendly Innovations in DTF Printing

As sustainability becomes a paramount concern in the printing industry, eco-friendly inks are making their way into Direct-to-Film printing. These inks are formulated to provide vibrant color without compromising environmental standards, appealing to a growing demographic of environmentally-conscious consumers. Manufacturers are increasingly focusing on creating inks that are not only effective but also minimize harmful components, ensuring that printing practices are more sustainable.

By adopting eco-friendly materials and processes, businesses stand to enhance their marketability. Eco-conscious consumers are more likely to support brands that align with their values, thus presenting companies that utilize green printing solutions with a competitive advantage. Staying informed about advancements in eco-friendly printing technology can help businesses maintain relevance while contributing to broader environmental goals.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve direct-to-film printing?

The DTF Gangsheet Builder is an innovative tool designed to streamline direct-to-film (DTF) printing by allowing multiple designs to be printed on a single sheet. This enhances print efficiency, reduces material waste, and optimizes workflow management, making it ideal for custom printing businesses.

What are the best heat press settings to use with the DTF Gangsheet Builder?

Optimal heat press settings when using the DTF Gangsheet Builder can vary based on the fabric type. Generally, it’s important to conduct tests to find the right temperature and pressure for each material. Standard settings often range from 320°F to 350°F with medium to heavy pressure for about 10-15 seconds.

How can I improve design placement on the DTF Gangsheet Builder?

To improve design placement using the DTF Gangsheet Builder, strategically arrange your images to minimize wasted space and ink. Utilizing design layout software can help you visualize and organize multiple elements efficiently, contributing to a more cost-effective printing process.

What print efficiency tips can be applied when using the DTF Gangsheet Builder?

To enhance print efficiency with the DTF Gangsheet Builder, focus on optimizing design layouts, choosing high-resolution images (minimum 300 DPI), and implementing proper color management practices. Additionally, using eco-friendly inks and advanced software tools can further streamline the printing process.

How does color management affect the results of using the DTF Gangsheet Builder?

Color management is crucial in DTF printing as variations in printer and ink types can affect the vibrancy of prints. To ensure consistency and maintain brand integrity, apply proper color profiles for each printer and conduct test prints before full-scale production when using the DTF Gangsheet Builder.

Which software is recommended for designing with the DTF Gangsheet Builder?

For designing with the DTF Gangsheet Builder, software such as Adobe Photoshop and CorelDRAW are popular choices due to their robust features. Additionally, specialized design layout software tailored for DTF printing can provide automated capabilities for more efficient designs and layouts.

| Key Points | Details |

|---|---|

| Direct-to-Film (DTF) Printing | Revolutionizes custom printing with vibrant designs directly on transfer films, enhancing efficiency and workflow. |

| Design Efficiency | Strategic placement minimizes waste and optimizes resources for cost-effective printing. |

| Image Quality | Use images at least 300 DPI for sharp, professional-grade prints. |

| Color Management | Implement printer-specific color profiles and perform test prints for consistency. |

| Heat Press Settings | Understand fabric-specific settings to ensure longevity and quality of prints. |

| Software Tools for Layout Design | Utilize specialized software like Adobe Photoshop or DTF-specific tools for efficiency. |

| Print Layering | Master base layer and adhesive application for increased print durability. |

Summary

DTF Gangsheet Builder is a groundbreaking tool that enhances the custom printing experience by allowing users to combine and print multiple designs efficiently onto a single sheet. This innovation not only optimizes material usage, reducing waste, but also significantly improves workflow management, making it a favored choice among printing businesses. By applying strategic design placement, maintaining high image quality, managing color accuracy, and understanding heat press settings, users can achieve superior results. Furthermore, as the DTF printing landscape evolves with eco-friendly inks and technological advancements, staying informed and adopting best practices will be key for businesses seeking growth and customer satisfaction.