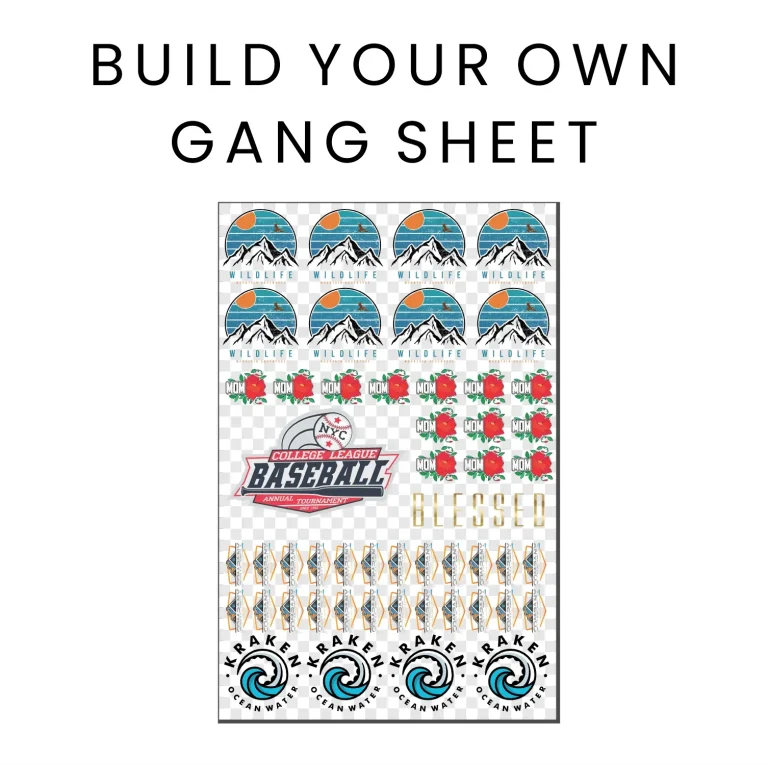

In the ever-evolving world of digital printing, the DTF Gangsheet Builder stands out as an essential tool for anyone engaged in DTF (Direct-to-Film) printing. This revolutionary software streamlines the printing workflow by allowing users to create gangsheet prints, enabling multiple designs to be printed on a single sheet efficiently. The optimization of printing workflow not only reduces material waste but also enhances productivity, making it a game-changer for designers and print operators alike. By using the DTF Gangsheet Builder, designers can focus on creating stunning prints while easily managing layout, spacing, and overall efficiency. In this article, we will delve into effective strategies for harnessing the full potential of the DTF Gangsheet Builder and optimizing your entire DTF printing process.

The DTF Gangsheet Builder is a comprehensive solution for those looking to enhance their direct-to-film printing capabilities, often referred to as gangsheet printing. By leveraging this innovative tool, users can optimize their design layouts and maximize output efficiency, which is crucial in today’s fast-paced printing industry. Whether you’re a seasoned professional or just starting out, mastering the art of designing DTF prints requires a keen understanding of workflow optimization and effective use of materials. Furthermore, incorporating effective software solutions allows for smoother processes, enabling a seamless transition from design conception to final printing. As we explore this topic further, we will uncover techniques that elevate your gangsheet printing game, ensuring high-quality results and reduced operational costs.

Benefits of DTF Gangsheet Printing

DTF Gangsheet printing revolutionizes the printing industry by allowing multiple designs to be printed simultaneously on a single film. This not only maximizes material use but also significantly reduces printing costs. The ability to efficiently group designs allows businesses to produce a wider variety of prints without the financial burden typically associated with smaller batch productions. Moreover, the optimized space usage ensures that each print comes out at the highest quality, with minimal waste.

Furthermore, using DTF Gangsheet printing can drastically improve turnaround times. With several designs being processed at once, companies can meet customer demands more quickly and efficiently. This method enables quicker responses to market trends, allowing businesses to stay competitive in an ever-changing industry. As such, embracing DTF gangsheet printing practices not only enhances productivity but also fosters innovation in product offerings.

Key Features of DTF Printing Software

When it comes to DTF printing, investing in specialized software is essential for optimizing your printing workflow. Advanced DTF printing software offers features such as automated layout arrangements, image optimization, and cutting path adjustments, making the gangsheet creation process smoother and more intuitive. These software solutions often allow for importing designs directly from design platforms, reducing the time spent in preparation and enhancing overall workflow efficiency.

Additionally, many DTF printing software programs include built-in color management tools that ensure consistency and accuracy in printed outputs. These tools help in applying ICC profiles that match the printer specifications, which is crucial in achieving the desired color fidelity. By employing efficient software solutions, printers can automate tedious tasks, minimize human error, and ultimately enhance their output quality.

Essential Design Considerations for Gangsheet Printing

Designing for DTF gangsheet printing requires careful consideration of layout and spacing. Utilizing templates that are specifically created for gangsheet tasks can provide a uniform starting point that simplifies the arrangement of designs. Such templates help visualize how designs will interact with one another on the printed film, allowing for optimal space utilization while preventing cutting complications. Moreover, using these templates can significantly decrease the likelihood of material waste.

Another crucial aspect is the consideration of color grouping when designing prints for gangsheet application. Grouping similar colors can optimize ink usage and enhance print quality, as it allows printers to handle similar hues in one processing phase. Careful arrangement of designs not only maximizes gangsheet space but also contributes to a more efficient and effective printing workflow.

Importance of Color Management in DTF Printing

Effective color management is paramount in DTF printing, particularly when striving for consistency across print batches. The use of accurate ICC profiles specifically tuned to a printer’s output ensures that the printed designs closely match the intended colors as seen on-screen. This level of precision not only improves the overall quality of the printed product but also builds customer trust, as clients receive exactly what they expect.

Neglecting color management in the DTF printing process can result in significant discrepancies between desired and actual outputs. Regular calibration of the printer is essential to maintain color accuracy over time. By focusing on proper color management techniques, such as regular maintenance and the use of calibrated profiles, printers can guarantee a level of quality that meets or exceeds industry standards.

Material Selection for High-Quality DTF Prints

Choosing the right materials plays a critical role in the success of DTF printing. High-quality DTF films and inks are fundamental to achieving vibrant prints that endure. Utilizing subpar materials can lead to degraded print quality, which in turn can generate a greater number of reprints and higher production costs. Investing in quality materials not only enhances the aesthetics of the final product but also contributes to overall operational efficiency.

Moreover, the durability and performance of inks used in DTF printing directly impact the lifespan and wear of prints on apparel. Printers should prioritize inks designed for DTF applications to ensure robust color and texture on various fabric types. Implementing these best practices in material selection can lead to superior print outcomes that satisfy both printer and customer expectations.

Enhancing Workflow Integration with DTF Printing

Integrating DTF printing into existing workflows can bring about considerable improvements in efficiency. By creating standardized processes and utilizing automation tools, businesses can streamline their production lines, reducing bottlenecks and enhancing the overall effectiveness of operations. This not only leads to faster turnaround times but also optimizes resource allocation, which is essential for keeping production costs low.

Furthermore, fostering synergy between DTF printing and other production methods allows for a more cohesive operational strategy. Companies that successfully integrate DTF printing into their workflows often experience a seamless flow of design from conception to production. This integration is vital for meeting modern market demands and ensuring that businesses remain agile and responsive.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a specialized tool designed for optimizing the layout of designs for DTF (Direct-to-Film) printing. By arranging multiple graphics on a single sheet efficiently, it maximizes the usable area, reduces material waste, and enhances production capacity. This workflow optimization tool allows printers to achieve higher efficiency in their printing processes.

How can I maximize efficiency using the DTF Gangsheet Builder?

To maximize efficiency with the DTF Gangsheet Builder, start by using customizable templates that suit your designs. Carefully plan the spacing and arrangement of your prints to minimize waste and ensure clean cuts. Group similar colors together to optimize ink usage and maintain print quality. By utilizing these strategies, you can significantly improve your DTF printing workflow.

What design tips should I follow when using the DTF Gangsheet Builder?

When using the DTF Gangsheet Builder, employ design tips such as utilizing pre-defined templates, ensuring adequate spacing between designs to prevent overlap, and layering designs with similar colors. These practices will help you optimize the gangsheet layout for size and quality, leading to improved output in your DTF printing projects.

What software is best for creating gang sheets for DTF printing?

The best software for creating gang sheets for DTF printing includes those specifically designed for this purpose, featuring tools like image optimization and automated layout adjustments. Many of these software solutions can integrate with existing design platforms, facilitating a smoother workflow and allowing for seamless DTF print preparation.

How important is color management in DTF printing, and how can I improve it?

Color management is crucial in DTF printing to ensure that the printed output matches on-screen colors. To improve color management, use ICC profiles tailored to your DTF printer, regularly calibrate your printer for color accuracy, and maintain your ink settings. This will enhance overall print quality and consistency in your DTF projects.

What materials should I use for optimal results in DTF printing with the Gangsheet Builder?

For optimal results in DTF printing when using the Gangsheet Builder, choose high-quality DTF films and inks that meet industry standards. Regular maintenance of your printer, including cleaning and alignment checks, is also essential to prevent printing issues and ensure the best output quality.

| Key Point | Description |

|---|---|

| Introduction | Optimizing workflow is crucial in DTF printing, and the DTF Gangsheet Builder is a key tool. |

| Understanding DTF Gangsheet | Maximizes printable area on each sheet to save costs and enhance productivity. |

| Design Tips | Use templates, ensure proper spacing, and group similar colors for optimized prints. |

| Software Utilization | Software tools can automate adjustments and enhance print quality, creating an efficient workflow. |

| Color Management | Install ICC profiles for color fidelity and calibration for accurate hues in prints. |

| Material Settings | Use high-quality films and inks; regular maintenance is essential to ensure consistent output. |

| Workflow Integration | Automation and standardized processes improve productivity and reduce turnaround times. |

Summary

The DTF Gangsheet Builder is an invaluable resource for any digital printing professional aiming to enhance their workflow efficiency. By employing the techniques outlined, such as utilizing templates, optimizing spacing, and managing color profiles, users can significantly maximize their output while minimizing waste. Quality materials and regular maintenance are paramount to ensure the longevity and fidelity of prints. Ultimately, integrating streamlined processes with the DTF Gangsheet Builder can transform printing operations, driving productivity and fostering a cost-effective environment in the competitive world of digital printing.