The DTF Gangsheet Builder is revolutionizing the way custom apparel is produced through the innovative Direct to Film (DTF) printing method. This essential tool maximizes design efficiency and creativity, allowing users to streamline the printing process for vibrant and professional results. As demand for personalized clothing continues to rise, understanding the DTF gangsheet builder becomes crucial for both new and experienced printers alike. This comprehensive guide will explore the latest advancements and best practices in DTF printing, empowering individuals to harness the full potential of gangsheet printing. From enhancing design capabilities to reducing production costs, the DTF gangsheet builder is your gateway to unlocking limitless creativity in the apparel industry.

In the dynamic realm of printing technology, the emergence of the Direct to Film (DTF) system and its accompanying gangsheet capabilities represents a significant shift towards efficiency and personalization. This advancement allows businesses to print multiple designs onto a single film, optimizing material usage while achieving high-quality results. Additionally, terms synonymous with this process, such as DTF design software and gangsheet creation, highlight the technical framework driving this innovative solution. With the growing accessibility of these tools, both budding entrepreneurs and established business professionals can elevate their custom printing ventures. As we delve deeper into the world of DTF printing and gangsheet assembly, readers will uncover the myriad benefits this platform has to offer.

Understanding DTF Printing Technology

DTF printing, or Direct to Film printing, is a cutting-edge technology that allows for high-quality images to be printed onto a special film. This film is then used to transfer designs onto various types of textiles, making it a versatile option for custom apparel. Unlike traditional methods such as screen printing, DTF enables vibrant colors and intricate designs that adhere well to fabrics with excellent durability. The process is largely efficient, as it minimizes material wastage while producing multiple designs on a single film sheet.

Moreover, DTF printing is particularly suitable for small to medium-sized businesses wanting to provide personalized apparel without compromising on quality. The advancements in ink technology, particularly in white ink formulations, have ensured that the print outcomes are both sharp and vivid. DTF also offers the ability to print on dark fabrics, something that has posed challenges for methods like DTG (Direct to Garment) printing. This flexibility makes DTF an attractive choice in the modern printing landscape.

The Benefits of Using a DTF Gangsheet Builder

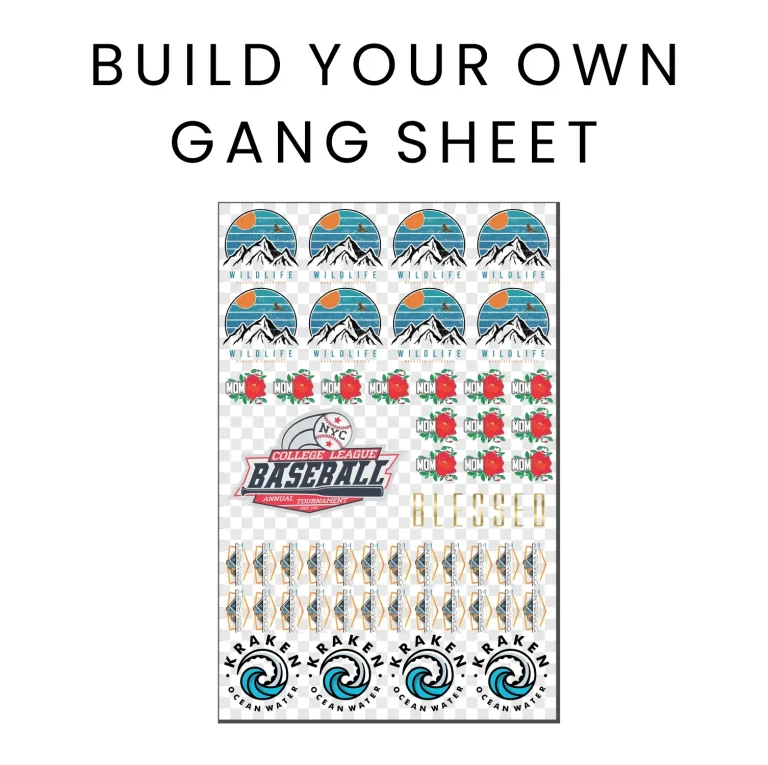

The DTF gangsheet builder is an essential tool that optimizes the process of DTF printing by enabling users to arrange multiple designs on a single sheet of film. This not only maximizes the use of resources but also significantly reduces printing costs. By grouping designs together, printers can achieve greater efficiency, making it a popular choice among apparel manufacturers seeking to streamline production while maintaining high quality.

Additionally, the gangsheet method minimizes downtime by enabling larger batches of prints to be prepared and processed at once. This efficiency is particularly beneficial for businesses that receive multiple custom orders, allowing them to meet deadlines without sacrificing quality. The ability to print multiple small designs simultaneously also caters to the burgeoning demand for personalized small batch orders effectively.

Recent Innovations in DTF Design Software

As technology evolves, so does the landscape of DTF design software. Modern solutions like FilmMaker and Ultradeco have revolutionized the way users create and manage their gangsheet designs. These software tools provide intuitive interfaces that simplify design arrangements, color management, and file preparation, thus inviting newcomers to the DTF printing arena. Users can easily bring their custom designs to life with features that optimize quality and ensure coherence across various print jobs.

Furthermore, these enhancements not only cater to user convenience but also address crucial factors like color accuracy and graphic resolution. Automatically adjusting settings like ink levels and print dimensions ensures that even those inexperienced with printing technology can produce high-quality outputs. As more robust design software becomes accessible, the barriers to entry in the DTF market continue to drop, enabling businesses of all sizes to thrive.

Mastering Best Practices for DTF Gangsheet Printing

To fully leverage the benefits of DTF gangsheet builders, it is essential to adhere to best practices that enhance print quality and efficiency. One crucial practice involves maintaining appropriate dimensions for all artwork, ensuring that designs are fully encompassed within the specified print area. This prevents cropping and ensures that details are preserved in the final output. Additionally, using high-resolution graphics is fundamental; low-quality images can result in pixelated prints, detracting from the overall appearance.

Moreover, understanding the printer settings specific to DTF technology plays an instrumental role in achieving successful prints. Familiarity with settings such as temperature, pressure, and print speed can significantly mitigate errors during the printing process. Following these guidelines not only reduces wasted material but also fine-tunes the quality of prints, leading to satisfied customers and increased efficiency for printing operations.

The Future of Custom Apparel with DTF Printing

The future of custom apparel lies within the realm of DTF printing technology. With its rapid advancements, more businesses are adopting the DTF gangsheet builder as a central tool in their production process. The growing demand for personalized fashion items, including unique prints and custom graphics, pushes the boundaries of creativity and business expansion in the apparel industry. As tools and technologies enhance the quality and efficiency of DTF printing, the possibilities for customized designs will become even more expansive.

Looking forward, as consumers continue to seek individuality and personalization in their clothing, businesses employing DTF methods can expect to thrive. Innovations in production, coupled with strategic marketing of custom apparel offerings, will allow printers to cater to diverse customer preferences. As the capabilities of DTF printing technology grow, so too will consumer expectations, paving the way for sustained growth in the custom apparel market.

Embracing DTF Printing for Sustainable Practices

Embracing DTF printing technology also aligns with the growing movement towards sustainable practices in the fashion industry. Traditional printing methods often involve significant waste and environmental impact. In contrast, DTF printing, especially through gangsheet techniques, minimizes material use and reduces chemical waste, making it a more eco-friendly option. By maximizing the effective use of printing resources, it helps businesses contribute positively to sustainability goals.

Furthermore, as businesses integrate DTF printing into their workflows, they can also adopt other sustainable practices, such as sourcing eco-friendly materials and inks. For those looking to establish a green identity, promoting DTF printing as part of their eco-conscious approach can boost brand loyalty and appeal to environmentally minded consumers. The marriage of technology and sustainability represents a crucial step towards a more responsible future in custom apparel production.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool used in Direct to Film (DTF) printing that optimizes the placement of multiple designs on a single film sheet. This method maximizes material usage and reduces waste, making it an efficient solution for custom apparel production.

How can I create custom apparel using the DTF Gangsheet Builder?

To create custom apparel with the DTF Gangsheet Builder, first design your artwork using specialized DTF design software like FilmMaker or Ultradeco. Then, arrange the designs on the gangsheet to ensure optimal layout. Finally, transfer the designs onto fabric using DTF printing technology.

What advantages does DTF printing offer over traditional printing methods?

DTF printing offers several advantages over traditional methods, including vibrant color reproduction, durability, and the ability to print on various textiles. Using a DTF Gangsheet Builder enhances these benefits by allowing multiple designs to be printed simultaneously, reducing costs and turnaround times.

Are there specific best practices for using a DTF Gangsheet Builder?

Yes, best practices for using a DTF Gangsheet Builder include maintaining appropriate artwork dimensions, using high-resolution graphics, and understanding your printer’s settings. These practices help ensure high-quality prints and minimize material wastage in the DTF printing process.

What recent developments are impacting the DTF Gangsheet Builder technology?

Recent developments impacting the DTF Gangsheet Builder technology include enhanced software solutions that simplify design processes, improvements in print quality due to better ink formulations, and increased accessibility through online tutorials and resources for users to learn and master DTF printing.

How has the market for DTF printing and gangsheet building evolved?

The market for DTF printing and gangsheet building has seen rapid growth, driven by rising demand for customized apparel. Businesses implementing DTF technology report benefits like reduced operational costs and quicker production times, making it an attractive option in the competitive printing landscape.

| Key Points | Details |

|---|---|

| Introduction | Overview of DTF printing and the significance of the DTF Gangsheet Builder. |

| What is DTF and Gangsheet Building? | DTF allows high-quality designs on film transferred to textiles. Gangsheet building maximizes film usage. |

| Recent Developments | Advancements in software, accessibility, quality improvements, and market growth in DTF printing. |

| Best Practices | Maintain dimensions, use high-quality graphics, and understand printer settings for optimal results. |

Summary

DTF Gangsheet Builder technology is revolutionizing the landscape of custom apparel printing by enhancing creativity and efficiency through innovative solutions. This guide serves to illuminate the essential aspects of DTF gangsheet building, which allows for efficient use of materials while achieving vibrant, durable designs on textiles. As advancements in technology and increased accessibility continue to empower users, the potential for creativity in this space is boundless. Whether you are a seasoned print professional or a beginner, utilizing the insights from this guide can pave the way for your success in the ever-evolving world of DTF printing.