The **DTF Gangsheet Builder** is revolutionizing the printing industry by merging cutting-edge technology with practical application, offering a streamlined approach to **DTF printing**. Unlike traditional printing methods, which often involve cumbersome setups and lengthy production times, the DTF Gangsheet Builder allows multiple designs to be printed on a single sheet, enhancing both efficiency and cost-effectiveness. As businesses explore innovative printing solutions, they find that DTF offers remarkable versatility across various fabric types, positioning it as a formidable alternative to screen printing and Direct-to-Garment (DTG) printing. Furthermore, with its ability to cater to batch jobs while minimizing waste, the DTF Gangsheet Builder meets the demands of modern print shops striving for sustainability and profitability. In this article, we will delve into the benefits and drawbacks of DTF printing compared to traditional methods, equipping you with the knowledge to choose the right technology for your business needs.

When evaluating the capabilities of the **DTF Gangsheet Builder**, it’s essential to understand its potential as part of the broader realm of modern printing techniques. This innovative machine enhances the Direct-to-Film (DTF) printing process by enabling the simultaneous printing of various designs, thus improving operational speed and efficiency. Print providers now have the opportunity to break away from the constraints of traditional practices like screen printing, which can be labor-intensive and costly. By leveraging the advantages of DTF technology, businesses can not only increase their production output but also enjoy significant cost-savings, making it an attractive option in the competitive landscape of fabric printing. In this discussion, we will compare DTF and its traditional counterparts, highlighting each method’s strengths and limitations.

Understanding DTF Printing Technology

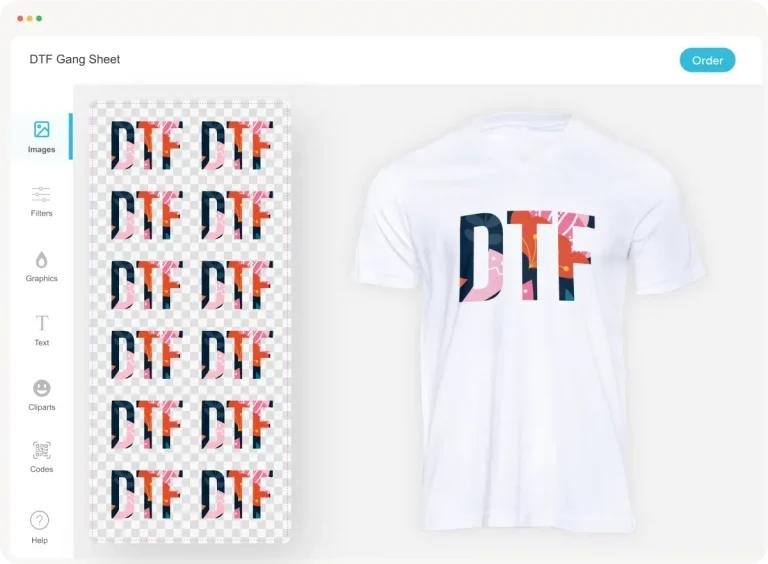

DTF printing, or Direct-to-Film printing, leverages new-age technology to provide an innovative alternative to traditional methods like screen printing. This process revolves around printing designs on a special film which is then heat-transferred onto textiles. The key to DTF’s effectiveness is its capability to yield detailed and vibrant prints on a variety of fabric types, making it a versatile option for modern print shops. Notably, the DTF Gangsheet Builder enhances this technique by allowing multiple designs to be printed seamlessly on a single sheet, thus maximizing efficiency in production runs.

As the demand for high-quality printed apparel rises, DTF technology presents an attractive solution for businesses looking to stay competitive. Its flexibility and ability to manage varying fabric types, whether cotton, polyester, or blends, gives it an edge over older techniques. Moreover, this modern method enables shops to navigate the bustling world of customized apparel easily, ensuring they meet customer needs with speed and precision. With features like the DTF Gangsheet Builder, printing operations can optimize their workflows and minimize waste, contributing positively to the overall bottom line.

The Efficiency of DTF Gangsheet Builder

One of the most compelling advantages of the DTF Gangsheet Builder lies in its efficiency. This tool enables print shops to create multiple designs on a single gang sheet, significantly reducing the time and effort required for setup and production. Unlike traditional printing techniques, which often necessitate separate screens or individual setups for each design, the DTF process allows for rapid production of several items at once. This efficiency is particularly beneficial for businesses dealing with high-volume orders or tight deadlines, as it enables them to fulfill customer demands without compromising on quality.

Furthermore, the DTF Gangsheet Builder contributes to minimizing material waste, a critical factor in production costs. By allowing various designs to fit neatly onto a single film sheet, print shops can maximize output while decreasing the amount of unused material. This aspect is not only cost-effective but also aligns with environmentally-conscious practices, a growing priority for many businesses today. In contrast, more traditional methods, such as screen printing, tend to incur higher waste levels due to the need for separate setups and excess inks, making the DTF approach the more sustainable choice.

Cost-Effectiveness of DTF Printing

Cost management is paramount for print shops, especially those starting out or looking to expand. The DTF Gangsheet Builder provides a pathway to significant cost savings by reducing the necessity for extensive equipment and materials typically associated with traditional printing methods like screen printing. Businesses can avoid high initial investments and ongoing costs tied to multiple inks and screens since DTF operates on a more streamlined and intuitive setup. This reduction in overhead can translate to higher profit margins for print shops, enabling them to allocate resources toward other areas of growth.

Additionally, the DTF method removes some of the barriers faced by small print businesses. With its less complicated setup requirements, it allows startups to enter the market more easily without the hefty financial burden often linked to entry through traditional methods. As a result, smaller shops can remain nimble and adapt to market trends or customer requests promptly, without being weighed down by excessive costs. Thus, the DTF Gangsheet Builder emerges as an essential tool for businesses determined to enhance profitability while maintaining excellent product quality.

Versatility of DTF Printing

DTF printing stands out for its exceptional versatility, accommodating a wide range of materials that include cotton, polyester, and various blends. This adaptability is a significant advantage over traditional methods, like screen printing, which might struggle with certain fabric types. The ability to print on diverse textiles opens up opportunities for print shops to cater to various market segments and customer preferences, driving sales and customer satisfaction. As consumer demand for custom apparel continues to rise, the versatility offered by DTF can provide a competitive edge.

Moreover, the DTF Gangsheet Builder enhances this versatility further by allowing multiple designs on a single sheet. This means that businesses can efficiently handle complex orders with various design requirements without the need for complicated setup processes. This feature not only saves time but also supports creativity by enabling designers to experiment with different prints without committing to a large production run in one specific style. As the garment printing industry evolves, DTF’s versatile capabilities ensure that print shops can remain relevant and responsive in a rapidly changing market.

Navigating the Learning Curve of DTF Technology

Transitioning from traditional printing methods to DTF presents a unique learning curve for many businesses. While the DTF Gangsheet Builder offers significant advantages in efficiency and cost-effectiveness, mastering the new technology requires adaptation and investment in employee training. Many print shop operators, especially those who have relied heavily on methods like screen printing, may find the new processes and equipment intimidating at first. However, embracing this shift is crucial for staying competitive in an industry marked by rapid technological advancements.

Engaging in comprehensive training programs and utilizing online resources can ease this transition and foster familiarity with DTF processes. Businesses might also consider taking small steps, integrating DTF technology gradually while continuing to use traditional methods until their team becomes proficient. This hybrid approach allows for maintaining steady operations as new workflows are evaluated and optimized. Overall, while the learning curve may pose challenges, the long-term benefits of adopting DTF technology are expected to outweigh initial difficulties.

Retaining the Benefits of Traditional Printing Methods

Despite the rise of DTF printing, traditional methods such as screen printing still have a dedicated place in the market. The established practices, proven techniques, and supply chain relationships around traditional printing provide significant reassurance for businesses steeped in these methods. Screen printing, in particular, is known for its durability and color vibrancy on selected materials, making it a preferred choice for specific niche markets focused on rich color and fabric longevity. Many businesses choose to retain their traditional printing alongside new technologies to benefit from both worlds.

Moreover, the experience accumulated over years of traditional printing can contribute to higher quality control standards in the production process. Businesses must weigh their priorities: whether to embrace the latest technology for efficiency or to maintain the quality and reliability established through years of proven methods. Ultimately, for print shops seeking a balanced approach, integrating modern solutions like DTF with the established practices of traditional methods can create a robust setup that meets diverse customer demands effectively.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a tool used in Direct-to-Film (DTF) printing that allows multiple designs to be printed on one sheet of transfer film. This process involves printing onto a special film, which is then heat-transferred onto garments, providing efficiency and minimizing material waste.

How does DTF printing compare to traditional printing methods like screen printing?

DTF printing via the Gangsheet Builder offers enhanced efficiency by enabling the simultaneous printing of multiple designs, reducing setup time compared to traditional methods like screen printing, which often require extensive preparation for each new design.

Can the DTF Gangsheet Builder be considered cost-effective for small businesses?

Yes, the DTF Gangsheet Builder is a cost-effective solution for small businesses as it minimizes film waste and decreases the need for multiple screen setups associated with traditional printing methods, thus improving profit margins.

What types of fabrics can be used with the DTF Gangsheet Builder?

The versatility of the DTF Gangsheet Builder allows it to be used on a variety of fabrics including cotton, polyester, and blends, making it more adaptable than many traditional printing methods that may be limited to certain materials.

Are there any challenges when transitioning to the DTF Gangsheet Builder from screen printing?

Yes, transitioning to the DTF Gangsheet Builder from traditional screen printing may present challenges, including a learning curve associated with new techniques and workflow adjustments that require time and practice to master.

What advantages does the DTF Gangsheet Builder offer for production speed?

The DTF Gangsheet Builder significantly enhances production speed by allowing multiple designs to be printed in one operation, which is especially beneficial in high-volume orders, thus meeting customer demands more quickly compared to traditional printing methods.

| Feature | DTF Gangsheet Builder | Traditional Methods |

|---|---|---|

| Efficiency | Prints multiple designs concurrently, reducing production time. | Requires setup for each design, which can lead to longer turnaround times. |

| Cost-Effectiveness | Lower film waste and no need for multiple setups translates to better profit margins. | Higher initial investment for screens and inks can lead to increased costs. |

| Versatility | Can print on various fabrics including cotton, polyester, and blends. | Limited to specific materials; may not cater to diverse fabric types. |

| Initial Investment | Higher setup costs for machines and materials may deter small businesses. | Well-established and familiar technology with established costs. |

| Learning Curve | Requires training and adjustment for new workflows. | Familiar processes are easier to manage and implement. |

| Color Quality | Offers good quality, though some limitations in color saturation compared to traditional methods. | Can produce vibrant colors and deep saturation, especially on certain materials. |

Summary

The DTF Gangsheet Builder is revolutionizing how print shops operate, blending efficiency, versatility, and cost-effectiveness into one streamlined solution. In contrast to traditional methods, it allows for faster production times and diverse fabric printing without extensive setup delays. While the initial investment and training may pose challenges, the long-term benefits of adopting DTF technology can significantly outweigh these hurdles. In summary, businesses aiming for growth should carefully evaluate their printing needs and consider integrating the DTF Gangsheet Builder into their operations for enhanced productivity and customer satisfaction.