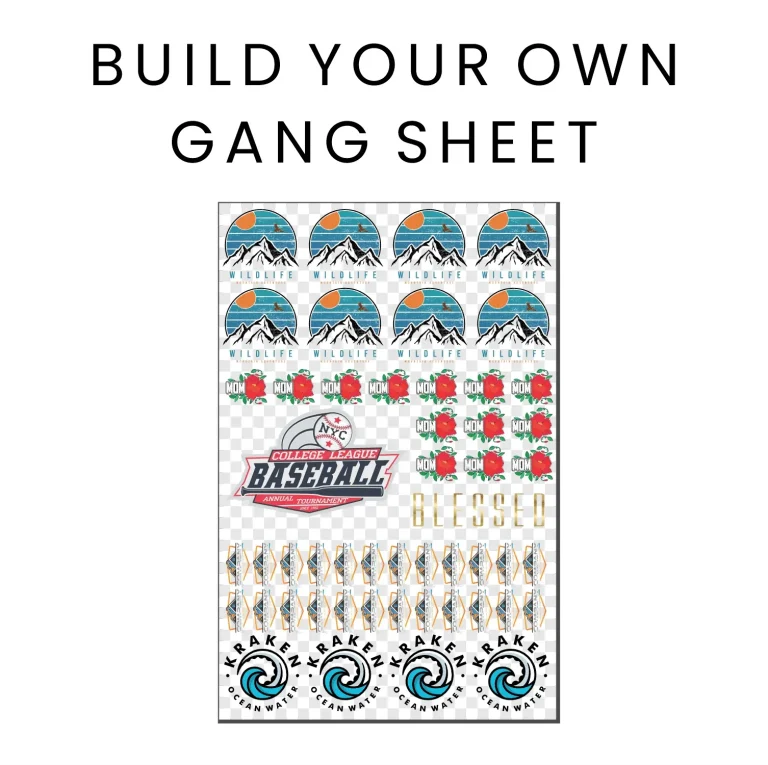

In the rapidly evolving world of fabric printing, the DTF Gangsheet Builder has emerged as a revolutionary solution that is transforming the industry. This innovative approach to DTF (Direct-to-Film) printing offers a significant advantage over traditional printing methods, allowing businesses to optimize their workflows and produce high-quality prints with remarkable efficiency. By enabling the simultaneous printing of multiple designs on a single sheet, the DTF Gangsheet Builder not only reduces material waste but also caters to the increasing demand for unique and personalized fabric printing solutions. As we delve deeper into the benefits of this cutting-edge technology, it becomes evident how DTF printing stands out with its vibrant colors and intricate details compared to screen printing. Whether for small runs or large productions, understanding the capabilities of DTF Gangsheet Builders is crucial for businesses aiming to stay ahead in a competitive market.

Exploring fabric printing through the lens of DTF Gangsheet Builders unveils a modern perspective on printing technology that emphasizes efficiency and creativity. This method, often referred to as Direct-to-Film printing, redefines how designs are transferred onto fabrics, contrasting sharply with traditional techniques like screen printing. Not only does this innovative printing technology allow for a diverse range of fabric applications, but it also brings forth significant advancements in color vibrancy and detail accuracy. With the option to print multiple designs simultaneously, businesses can cater to varying customer demands with ease, marking a notable shift from older, more conventional printing practices. As we investigate the intricacies of this contemporary printing solution, it is essential to understand not only its advantages but also how it fits within the broader landscape of traditional fabric printing methods.

Exploring the Advantages of DTF Gangsheet Builders

DTF Gangsheet Builders offer numerous advantages that set them apart from conventional printing methods. One of the significant benefits is their ability to streamline production by allowing the printing of multiple designs on a single gangsheet. This feature not only maximizes material usage but also significantly reduces waste— a common issue with traditional printing techniques. As businesses increasingly focus on sustainability, this eco-friendly aspect of DTF printing makes it a favorable choice for many.

In addition, DTF Gangsheet Builders are known for their cost-effectiveness, especially when it comes to small batch orders. Unlike traditional screen printing, which often demands minimum orders to justify setup costs, DTF allows businesses to cater to smaller client needs without incurring heavy losses. This flexibility opens new revenue streams and helps businesses remain competitive in the ever-evolving fabric printing market.

Understanding the DTF Printing Process

The DTF printing process is a revolutionary approach that starts with direct inkjet printing onto a special film. After the design is printed, a polymer adhesive is applied, followed by a powder adhesive that bonds the ink to the film. The process culminates in a heat transfer stage where the design is applied to the fabric. This method is particularly advantageous as it allows for high-quality prints with stunning color vibrancy, characteristics that are increasingly sought after in fabric printing.

Moreover, the speed of the DTF printing process is noteworthy. Unlike more labor-intensive traditional methods such as screen printing, which can be time-consuming and cumbersome, DTF technology allows for quicker turnaround times. This efficiency is critical in today’s fast-paced market, where customized orders are increasingly prevalent. Businesses can thus respond promptly to client demands, enhancing customer satisfaction and loyalty.

Comparative Benefits: DTF Printing vs. Traditional Methods

When comparing DTF printing with traditional methods such as screen printing, several key benefits emerge. For instance, DTF printing excels in producing intricate designs and vibrant colors on a wide range of fabrics, unlike some traditional techniques that may have limitations in terms of color variety and fabric compatibility. This versatility means that businesses can meet diverse client demands without the constraints of traditional printing methods.

Additionally, DTF technology offers better pricing flexibility for smaller orders. Traditional screen printing typically becomes cost-effective only when producing items in bulk. However, DTF allows for competitive pricing on smaller batches, enabling businesses to profit from a broader customer base, including those who seek small runs for personalized services or special events.

Addressing Challenges in DTF Technology

Despite its advantages, DTF printing is not without challenges. One significant hurdle is the learning curve associated with mastering the new technology. Businesses transitioning from traditional printing methods may find adapting to the nuances of DTF systems overwhelming at first. This adjustment period can pose a barrier to rapid adoption, with companies needing to invest time in training personnel and familiarizing them with the operational aspects of DTF Gangsheet Builders.

Moreover, while the initial costs for DTF equipment can be higher, businesses must consider the long-term benefits. Investing in DTF technology may lead to substantial cost savings in the long run due to increased efficiency and reduced material waste. Being aware of these trade-offs is imperative for businesses contemplating whether to transition to DTF printing or stick with time-honored methods.

The Future of Fabric Printing: DTF vs. Traditional Solutions

As the fabric printing landscape evolves, the choice between DTF and traditional methods will be shaped by consumer demand and technological advancements. While traditional screen printing has built a solid reputation for durability and high volume, DTF printing continues to make inroads by offering customization and flexibility. Businesses need to evaluate their specific contexts to determine which method aligns best with their operational capabilities and customer expectations.

The trend towards personalization is becoming more pronounced, with DTF Gangsheet Builders poised to address this shift effectively. As businesses strive to stand out in a crowded market, DTF’s ability to deliver small orders with high-quality prints has significant appeal. Moving forward, the printing technology adopted will greatly depend on business models and their adaptability to consumer preferences.

Finding the Right Balance in Printing Solutions

In the quest to find the most effective printing solutions, businesses must weigh their goals against the capabilities of DTF and traditional methods. For companies heavily focused on bulk orders and established designs, traditional screen printing may still serve as a reliable choice. Conversely, businesses aiming to attract a niche market with unique, artistic designs could benefit immensely from DTF Gangsheet Builders.

Ultimately, the choice between DTF and traditional solutions should align with strategic objectives and market demands. As fabric printing technology continues to advance, businesses will have better tools at their disposal to meet diverse client expectations. Making informed decisions based on comprehensive analyses of both options can lead to sustained growth and competitive advantage in the fabric printing arena.

Frequently Asked Questions

What are the advantages of using DTF Gangsheet Builder in fabric printing?

DTF Gangsheet Builders offer several advantages in fabric printing, including cost-effectiveness for small batches, enhanced color vibrancy, and versatility across various fabrics. This technology allows for multiple designs to be printed on a single sheet, thereby optimizing material usage and reducing waste, which is a significant advantage over traditional printing methods.

How does DTF printing technology differ from traditional screen printing?

DTF printing technology differs from traditional screen printing in its efficiency and setup requirements. Unlike screen printing, which requires a dedicated setup for each color, DTF allows for quick, multi-design printing on a single sheet, catering to smaller runs and reducing turnaround times, making it ideal for businesses needing rapid customization.

Can DTF Gangsheet Builders print on all types of fabrics?

Yes, DTF Gangsheet Builders are highly versatile and can print on a variety of fabrics including cotton, polyester, and blends. This flexibility allows businesses to cater to a wider range of client needs, unlike traditional methods that may be limited to specific materials.

What should businesses consider when investing in DTF Gangsheet Builders?

When investing in DTF Gangsheet Builders, businesses should consider the initial equipment cost, the learning curve associated with adopting the new technology, and their specific production needs. While the startup costs can be higher than traditional printing, the long-term savings and efficiency may justify the investment, particularly for those focusing on smaller orders or custom designs.

How does color vibrancy in DTF printing compare to traditional methods?

DTF printing is known for its superior color vibrancy and detail, often outperforming traditional methods like screen printing, especially for intricate designs. This capability allows businesses to differentiate themselves in a competitive market by offering high-fidelity prints that make a strong visual impact.

What are the potential challenges of using DTF Gangsheet Builders?

Potential challenges of using DTF Gangsheet Builders include a steeper learning curve for users familiar with traditional printing methods and the initial higher cost of the equipment. However, these challenges can be overcome with proper training and understanding of the technology’s benefits in the long run.

| Key Points | DTF Gangsheet Builders | Traditional Printing Methods |

|---|---|---|

| Utilizes Direct-to-Film technology for printing | Allows printing of multiple designs on a single sheet, reducing waste | Well-established screen printing techniques for large volumes |

| More cost-effective for small batches and custom orders | Provides enhanced color vibrancy and detail | Focuses on durability for larger production runs |

| Versatile usage on various fabrics | Requires investment in specialized equipment | Relies on physical setups for each design and color |

| May have a steep learning curve for some users | Adapts to modern consumer demands | Proven reliability for high-volume printing |

Summary

DTF Gangsheet Builder serves as a revolutionary tool in the fabric printing industry, combining efficiency with quality and adaptability to meet the diverse needs of modern businesses. With the capability to produce highly detailed designs on various fabric types while optimizing material use, DTF Gangsheet Builders represent the future of personalized printing solutions. As businesses assess their production needs, it’s essential to weigh the advantages of DTF technology against traditional printing methods, fostering informed decisions that enhance customer satisfaction and operational efficiency.