The DTF Gangsheet Builder is revolutionizing the custom apparel printing industry by offering an efficient and cost-effective way to produce vibrant designs on a variety of fabrics. Unlike traditional printing methods such as screen printing and DTG printing, DTF printing utilizes a unique process that compresses multiple images onto a single film sheet, optimizing production and reducing waste. This innovative approach not only enhances productivity but also aligns with the increasing demand for sustainable printing practices among consumers. As businesses seek to stay competitive in an evolving market, understanding the benefits of the DTF Gangsheet Builder becomes paramount. It’s time to explore how this technology can elevate your custom apparel offerings while addressing the complexities of modern printing needs.

In the realm of garment decoration, the DTF Gangsheet Builder stands out as a cutting-edge solution that blends creativity with productivity. This method, which allows multiple designs to be stylishly printed onto a single film, contrasts sharply with traditional options like screen printing and direct-to-garment (DTG) processes. As companies pivot towards more sustainable printing solutions, the DTF technique not only meets high-quality demands but also enhances operational efficiency. Embracing this advanced printing approach positions businesses to satisfy an increasingly discerning clientele, while still maintaining a focus on environmental considerations. Thus, an understanding of DTF technology is essential for anyone involved in the custom apparel printing landscape.

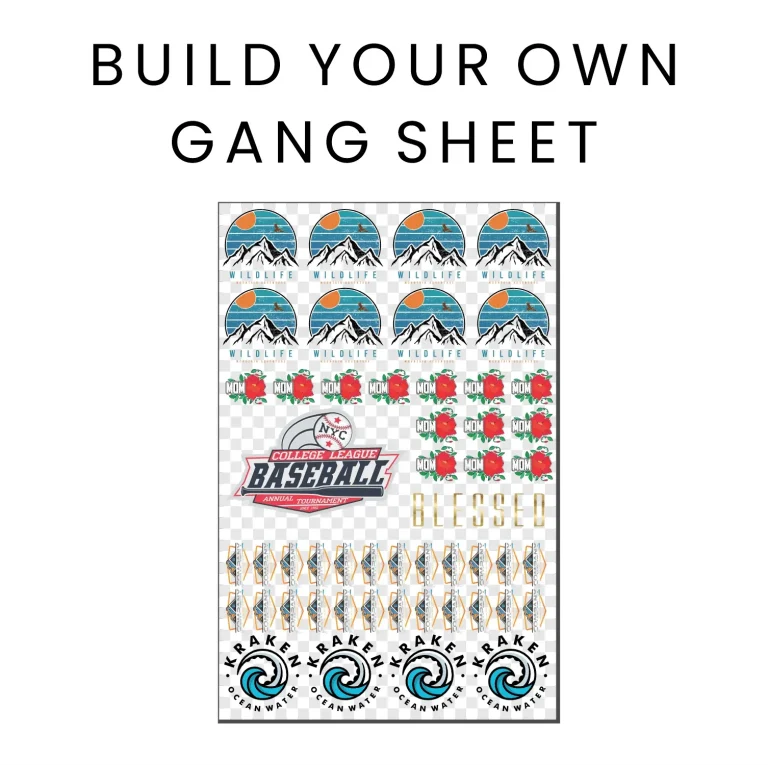

The Advantages of DTF Gangsheet Building

DTF Gangsheet Building revolutionizes the way custom apparel is produced by blending efficiency with flexibility. This innovative technique allows multiple designs to be printed on a single film, drastically reducing material waste and production costs. For businesses, especially small to medium-sized enterprises, this means that they can offer diverse product ranges without incurring high setup costs typical of traditional printing methods like screen printing and DTG printing. The ability to print high-quality images directly onto films enhances the appeal of final products, drawing in customers looking for unique designs.

Furthermore, the DTF process is streamlined, involving fewer manual steps compared to older techniques. By eliminating the need for extensive manual setup and multiple screens used in screen printing, DTF allows for quicker production times. This is particularly beneficial in a fast-paced market where customers expect rapid turnaround times on their apparel orders. The versatility of DTF also opens doors to prints on different fabric types—whether cotton, polyester, or blends—creating endless possibilities for custom apparel printing.

Understanding Traditional Printing Methods

While DTF Gangsheet Building is gaining traction, traditional printing methods, such as screen printing and DTG printing, have solidified their place in the custom apparel landscape. Screen printing is favored for its durability and ability to produce vibrant colors, making it ideal for large orders. It utilizes a time-tested process that ensures long-lasting images, making it a reliable choice for businesses looking to create high-quality apparel. However, its setup can be time-consuming, particularly when dealing with intricate designs, which can limit creativity if not managed properly.

DTG printing, on the other hand, has emerged as a strong contender for smaller batch sizes, allowing intricate designs to be printed directly onto garments. Despite its advantages, DTG often doesn’t achieve the same vibrancy as screen printing and may require specialized ink to meet durability standards. Both traditional methods offer distinct advantages, yet they present a challenge for businesses striving for quick, custom solutions, showcasing the importance of understanding each method’s capabilities in the context of production needs.

Exploring the Pitfalls of DTF vs. Traditional Printing Methods — Considerations for Businesses

Despite the benefits of DTF Gangsheet Building, there are disadvantages to consider, particularly when comparing durability with traditional printing methods. Users have reported that DTF prints, although vibrant and detailed, may not endure the test of time as well as those produced by screen printing. Frequent washing can affect print integrity, posing a concern for businesses whose customers prioritize long-lasting quality in their apparel. Hence, understanding the longevity of these prints is crucial for companies wanting to align their offerings with consumer expectations.

Moreover, the initial investment for DTF printing equipment can be significant, which might deter new businesses entering the custom apparel market. This contrasts with traditional methods that have established practices and equipment availability, allowing for a more accessible entry point. It’s vital for businesses to evaluate their specific needs, customer bases, and the potential return on investment when choosing between DTF and traditional printing methods.

Environmental and Sustainability Considerations in Apparel Printing

As the demand for sustainable practices grows, it is essential for custom apparel businesses to consider the environmental impact of their printing methods. DTF printing is often viewed as a more environmentally friendly option compared to traditional methods. The ability to use biodegradable inks and reduce waste through gangsheet printing aligns with the increasing consumer preference for eco-friendly apparel. This shift allows businesses leveraging DTF technology to tap into a market segment that prioritizes sustainability.

On the other hand, traditional printing methods like screen printing often generate considerable waste through screens and inks, which may not be as easily recyclable. However, many companies in the screen printing industry are also innovating, adopting more sustainable practices to reduce their environmental footprint. Businesses must weigh their printing method options against sustainability goals, discerning how their choices can enhance brand perception and customer loyalty.

Market Trends in Custom Apparel Printing

As the custom apparel industry evolves, new trends are driving changes in printing methods. The rise of DTF printing techniques reflects a market shift towards more adaptable solutions that meet diverse customer demands while maintaining cost-effectiveness. Enhanced technology now allows for rapid production while delivering high-quality outcomes, which is appealing to budget-conscious retailers looking to stay competitive in an ever-changing marketplace. This trend indicates a future where DTF printing may dominate, particularly among startups seeking efficiency.

Despite this trend, traditional methods are far from obsolete. Research indicates that while new printing technologies emerge, many companies still rely on screen printing due to its reputation for durability and quality in larger runs. This coexistence of methods illustrates a broader industry trend embracing a hybridization of printing techniques, allowing businesses to cater to diverse orders and customer preferences without sacrificing quality.

Making the Right Choice for Your Custom Apparel Business

Ultimately, the choice between DTF Gangsheet Building and traditional printing methods hinges on individual business needs. Factors such as volume, budget, and the desired quality are critical in determining the best approach. For those seeking quick production times with flexibility, DTF might be the ideal option, especially when aiming to produce varied designs without overwhelming costs.

Conversely, businesses that prioritize print durability and high-quality finishes may find traditional methods more suited to their operations. Staying informed about industry developments will empower custom apparel companies to make the best choices matching their quality, efficiency, and sustainability goals. By understanding the nuances of each printing technique, businesses can strategically position themselves for success in the dynamic custom apparel market.

Frequently Asked Questions

What are the benefits of using the DTF Gangsheet Builder compared to traditional printing methods?

The DTF Gangsheet Builder offers several advantages over traditional printing methods such as screen printing and DTG printing. These include cost-effectiveness, as it allows for multiple designs to be printed on one sheet, reducing per-unit costs. The DTF process is also less labor-intensive and quicker, enabling businesses to streamline production and minimize errors. Additionally, DTF printing is versatile, adhering well to various fabric types, making it ideal for a diverse range of custom apparel.

Is DTF printing more sustainable than traditional printing methods?

Yes, DTF printing can be more sustainable than traditional printing methods. Many DTF printers use biodegradable inks and waste-reducing techniques associated with gangsheet printing. As businesses increasingly focus on eco-friendly practices in custom apparel printing, DTF Gangsheet Builder aligns with consumer demands for sustainability, helping companies to lower their environmental footprint while producing high-quality prints.

How does the durability of DTF prints compare to screen printing and DTG printing?

While DTF prints can achieve vibrant colors and intricate designs, their durability compared to traditional printing methods like screen printing is sometimes questioned. Screen printing is well-known for producing long-lasting prints that withstand numerous washes. However, DTF prints can be durable if properly applied, making them suitable for various garments, although it’s crucial to be aware of potential longevity issues compared to traditional methods.

What type of garments can I print on using the DTF Gangsheet Builder?

The DTF Gangsheet Builder is versatile and works well on a variety of fabric types, including cotton, polyester, and blends. This adaptability gives businesses the ability to cater to different customer preferences and expand their product offerings in custom apparel printing. Whether it’s t-shirts, hoodies, or sportswear, DTF printing can deliver high-quality results across various textiles.

What is the initial investment required for DTF Gangsheet printing compared to traditional methods?

The initial investment for DTF Gangsheet printing can be significant, as it requires purchasing specialized equipment such as DTF printers and heat transfer presses. While this upfront cost may deter some entrepreneurs, it is essential to consider the long-term cost savings due to lower per-unit costs and reduced waste. In contrast, traditional methods like screen printing also require substantial investment, particularly for setup and materials, but may offer different longevity benefits.

Can DTF Gangsheet printing handle small batch sizes effectively?

Yes, DTF Gangsheet printing is particularly effective for small batch sizes. Unlike traditional methods like screen printing, which may require lengthy setup processes for each design, DTF allows multiple designs to be printed simultaneously on one film sheet. This not only saves time but also makes it an ideal option for customized orders and small runs in the custom apparel printing market.

| Feature | DTF Gangsheet Building | Traditional Printing Methods |

|---|---|---|

| Cost-Effectiveness | Lower cost per unit by consolidating designs on one sheet, reducing waste. | Higher setup costs for initial runs, beneficial for large volumes but not for small batches. |

| Production Process | Less labor-intensive with quicker turnaround and reduced human error. | More labor-intensive and longer setup times, especially for multi-color designs. |

| Versatility | Adheres well to a variety of fabric types, catering to diverse customer preferences. | Limited to certain materials; best results with specific fabric types. |

| Durability | Prints may fade after repeated washes compared to traditional methods. | Renowned for durability, maintaining print integrity over time. |

| Initial Investment | High upfront costs for specialized equipment may deter new businesses. | Less initial equipment cost for basic setups; however, may need additional tools for large runs. |

Summary

DTF Gangsheet Builder revolutionizes the custom apparel industry by providing a cost-effective and versatile printing solution that meets the diverse needs of today’s businesses. By allowing multiple designs to be printed on a single sheet, this innovative method not only reduces production costs but also enhances efficiency compared to traditional printing methods. As customer preferences shift towards sustainable and high-quality outputs, the advantages of DTF Gangsheet Building become increasingly clear. Whether you’re a small business looking to minimize costs or an enterprise aiming to maintain high quality, understanding the benefits and limitations of DTF can empower you to make informed decisions that enhance your operational success.