DTF transfer, short for Direct-to-Film transfer, has emerged as a game-changing technique in the world of custom printing. This innovative process allows you to create stunning fabric designs with vibrant colors and intricate details, making it perfect for both hobbyists and professionals. In this guide, we will delve into how to create DTF transfers, exploring the essential steps involved in the DTF printing process, from selecting the best DTF materials to mastering the art of designing transfers. By the end of this journey, you’ll be well-equipped to embark on your own DIY DTF printing projects, bringing your creative visions to life on fabric like never before. Join us as we transition from concept to creation and unravel the potential of DTF transfers.

Direct-to-Film application, often referred to as DTF printing, is revolutionizing the fabric customization landscape. This method, which transfers vibrant ink designs onto various textiles, is rapidly becoming the preferred choice for many who seek high-quality prints. With the capabilities to produce intricate artwork, it appeals to both creative enthusiasts and commercial printers. The configuration of DTF systems—including film, ink, and adhesives—opens up a world of possibilities for unique apparel and accessory design. Let’s explore how you can harness these innovative techniques to fully realize your artistic ambitions.

Understanding the DTF Printing Process

DTF printing is a groundbreaking method that revolutionizes how we approach fabric decoration, allowing creatives to print detailed designs directly onto a special film. This process not only enhances vibrancy but also offers unmatched versatility compared to traditional printing methods. As the application of DTF transfers grows, understanding the intricacies of the process becomes essential for anyone looking to become proficient in fabric printing.

At the core of DTF printing is the combination of heat and pressure to bond high-quality inks to fabric. The process entails printing your design onto a DTF transfer film, which is then treated with a special adhesive powder that helps to ensure the design adheres properly to the fabric during the heat press application. This unique method allows for the creation of intricate patterns and colors that remain vibrant over time, making DTF a popular choice among both hobbyists and professional crafters.

Choosing the Best DTF Materials for Success

Selecting the right materials is fundamental to achieving the best results in DTF printing. The quality of the transfer films, inks, and even the fabrics you use can significantly impact the transfer’s longevity and vibrancy. High-quality DTF transfer films are essential as they are specifically designed to interact with DTF inks, ensuring proper adhesion during the heat transfer process. These films must be compatible with the type of inks used to prevent issues during printing.

Additionally, using high-grade DTF printing inks is crucial. These inks are formulated to withstand repeated washing while retaining their color vibrance. When paired with the appropriate fabrics, such as cotton, polyester, or blends, DTF transfers can produce eye-catching designs that last. Therefore, investing time and resources into selecting the best DTF materials is pivotal in making your printing endeavors successful.

Design Software Choices for Creating DTF Transfers

Before diving into the creation of your DTF transfers, it is vital to choose the right design software that aligns with your specific needs. Popular programs like Adobe Illustrator and CorelDRAW provide robust features for creating intricate designs. Alternatively, free options like Inkscape offer user-friendly interfaces that can cater to beginners without compromising on essential functionalities needed for designing transfers.

When selecting design software, look for tools that support high-resolution outputs and various formats compatible with DTF printing. The ability to manipulate text and shapes effectively while working in a layered environment can enhance the creativity of your designs. Ultimately, the right software not only streamlines your workflow but also elevates the quality of your DTF transfers, allowing you to bring your artistic vision to life.

Preparing Your Artwork for DTF Printing

Preparing artwork for DTF transfers is a critical stage that directly influences the final output quality. Start with high-resolution images, ideally 300 DPI, to ensure your details translate well onto the fabric. Using the CMYK color mode is recommended as it allows for accurate representation of colors during printing. Taking the time to ensure that your design is not only visually appealing but also correctly sized for the fabric will help prevent common pitfalls associated with misalignment and distortion.

Furthermore, consider the overall aesthetic of your design elements. These include the placement and layering of graphics to create the best visual impact. Keep in mind the fabric’s surface and how it might interact with your colors and details to avoid blending issues. The better prepared your artwork, the more successful your DTF transfer will be, showcasing your design clearly and vibrantly on the final product.

Step-by-Step Guide to the DTF Printing Process

Executing the DTF printing process requires adherence to specific steps to ensure a successful transfer from film to fabric. Start by properly setting up your printer with the right DTF transfer film. This setup is crucial; using incorrect settings can lead to subpar prints and wasted materials. Be meticulous as you print your design onto the DTF film, ensuring that fine details are reproduced accurately to reflect your original artwork.

Once the design is printed, it is essential to immediately apply the powdered adhesive while the ink is still wet. This step is vital, as it helps the design adhere during the heat transfer process. Following this, curing the design according to the adhesive manufacturer’s instructions will enhance its durability. Each of these steps plays an integral role in achieving a successful DTF transfer, from the printer setup to the final heat application.

Successful Heat Transfer Application Techniques

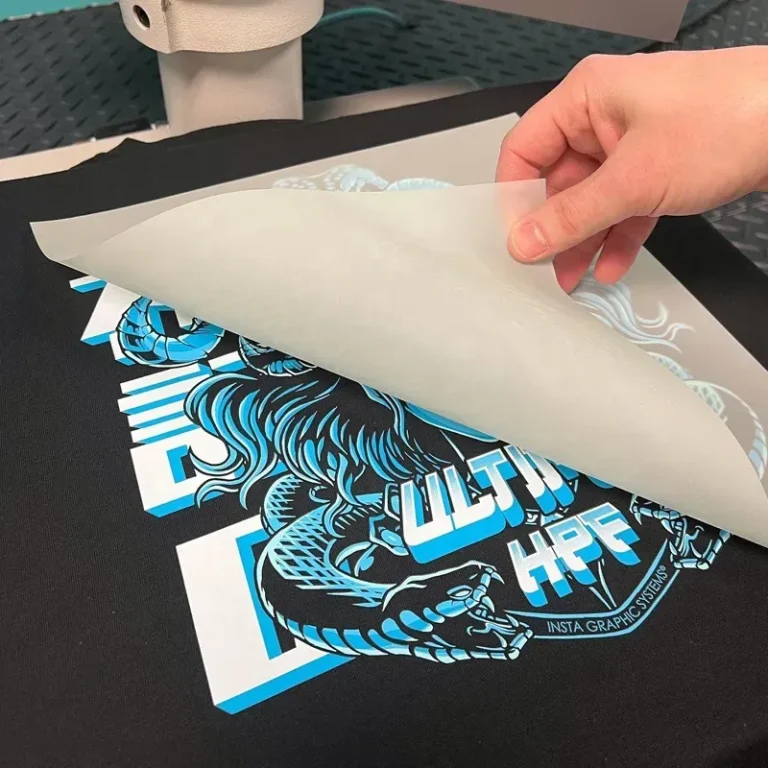

Mastering the heat transfer application is critical for achieving lasting results with your DTF transfers. Begin by positioning the printed film correctly on the garment, ensuring it is aligned perfectly before pressing. Using a protective sheet, cover the transfer to prevent any damage during the application of heat. The use of a heat press machine set to the manufacturer’s recommended temperature and pressure is crucial—this specificity ensures the best adherence and finish for your designs.

After applying the heat for the specified time, allow the transfer to cool before peeling the film away. This cooling period is essential, giving the design time to bond firmly with the fabric. Adequate attention to these details not only leads to successful transfers but also helps maintain the longevity and vibrancy of the designs, making them stand out for years to come.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves printing your design onto a special transfer film using DTF inks. Once printed, an adhesive powder is applied to the wet ink, which bonds with the design. The transfer is then heat applied to the fabric, allowing the design to adhere securely, resulting in vibrant and detailed prints.

How to create DTF transfers using design software?

To create DTF transfers, first select appropriate design software such as Adobe Illustrator or Inkscape. Create your design at a high resolution (300 DPI), use the CMYK color mode for accurate printing colors, and ensure your file format is compatible for printing. Finally, export your design to send it to the printer.

What are the best DTF materials to use for effective transfers?

The best DTF materials include DTF-specific transfer films that ensure optimal adhesion, and DTF printing inks that resist fading and maintain their color vibrancy after washing. Choose high-quality films and inks to guarantee successful and durable transfers on your garments.

Can I do DIY DTF printing at home?

Yes, DIY DTF printing at home is possible! You’ll need a DTF-compatible printer, special transfer films, DTF inks, and a heat press. Follow the DTF printing process closely, ensuring proper settings and materials to create professional-quality transfers from the comfort of your home.

What are the key considerations when designing transfers for DTF printing?

When designing transfers for DTF printing, focus on high-resolution images (at least 300 DPI), use the CMYK color mode for color accuracy, and ensure the sizing and placement are suitable for the fabric. Attention to these details can significantly enhance the quality of your final product.

How can I ensure the durability of my DTF transfers?

To ensure the durability of DTF transfers, use high-quality materials, including the correct transfer films and inks. Follow proper application techniques with adequate heat and pressure during the transfer process, and adhere to washing instructions to maintain the quality and longevity of your design.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A process of printing designs onto a special film and transferring it to fabric, suitable for intricate and vibrant designs. |

| Choosing Design Software | Use programs like Adobe Illustrator or CorelDRAW, ensuring user-friendliness and file compatibility. |

| Selecting Materials | Opt for DTF-specific films and inks to ensure durability and vibrant results in your designs. |

| Preparing Artwork | High-resolution images (300 DPI) in CMYK color mode are essential for accurate printing and design placement. |

| The Printing Process | Steps include printer setup, printing the design, applying adhesive, and curing it correctly for adhesion. |

| Heat Transfer Application | Proper positioning, covering, and pressing with exact temperature and pressure settings are crucial for success. |

| Post-Processing Care | Careful peeling of the transfer and following washing instructions to maintain design integrity is important. |

Summary

DTF transfer is a transformative method of fabric printing that allows users to bring their creative visions to life. By mastering the steps from selecting the right software to preparing artwork and applying transfers, you can achieve stunning results that showcase detailed designs on various fabrics. Understanding each phase, including the importance of high-quality materials and proper heat application techniques, is vital to ensuring that your DTF transfer not only looks great but lasts over time. As you dive into this exciting printing technique, remember that attention to detail and practice will elevate your craft, making your DTF transfer projects stand out.