DTF transfers are revolutionizing the way designs are printed onto fabrics, providing a vibrant and durable alternative to traditional methods. As the popularity of Direct-to-Film (DTF) printing continues to rise, it’s essential for users, especially beginners, to be aware of common pitfalls that can hinder the quality of their prints. Many novice printers often fall victim to DTF printing mistakes that could easily be avoided with a little knowledge and practice. This blog post will highlight five crucial DTF application techniques and tips to ensure you achieve the best results with your projects. By understanding factors like fabric compatibility for DTF, printer maintenance, and post-printing care, you’ll not only enhance your prints but also enjoy a more fulfilling printing journey.

Direct-to-Film (DTF) transfers, often regarded as a game-changer in the fabric printing arena, allow for intricate designs to be effortlessly transferred onto a variety of textiles. This innovative printing method opens the door to vibrant, long-lasting graphics that can elevate any fabric product. However, many individuals new to the DTF process might encounter challenges that can affect their outcomes. Techniques for applying DTF transfers, ensuring the right fabric combination, and maintaining your printing equipment are key elements for success. By embracing these concepts, you can navigate the world of DTF printing with confidence, creating stunning, durable designs.

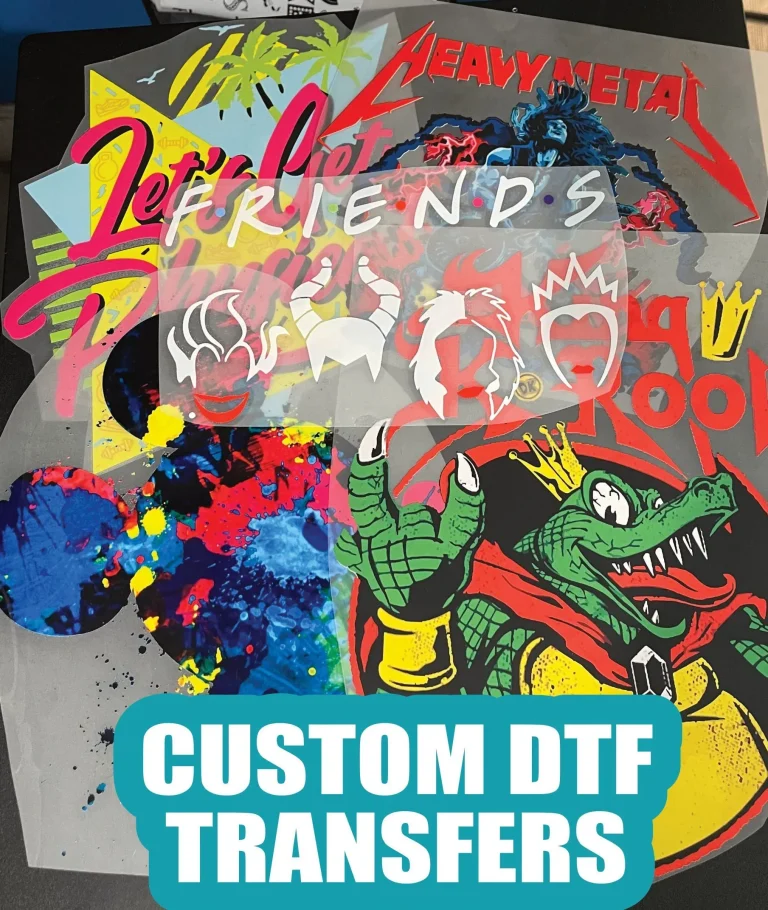

Avoiding DTF Printing Mistakes

DTF printing mistakes can significantly affect the outcome of your projects if not addressed properly. Common pitfalls such as using low-resolution images or failing to convert color formats can result in disappointing prints. To ensure that your designs turn out beautifully, always make sure your images are at least 300 DPI and converted to CMYK color format. This will allow your prints to be vibrant and true to the original design, significantly reducing the likelihood of errors due to poor file quality.

Additionally, many novice printers forget to check their file dimensions against the print area on the transfer film. Discrepancies in size can lead to unwanted cropping or distortion in the final print. By focusing on proper file preparation, including resolution and color settings, you can avoid these critical mistakes and achieve an impressive print quality.

Frequently Asked Questions

What are the common DTF printing mistakes to avoid?

Common DTF printing mistakes include neglecting proper file preparation, using incompatible fabrics, incorrect application techniques, overlooking post-printing care, and inadequate equipment maintenance. Addressing these issues can significantly improve the quality and durability of your DTF transfers.

How should I prepare my files for DTF transfers?

When preparing files for DTF transfers, ensure they are at least 300 DPI for sharpness and in CMYK color mode for accurate printing. Double-check dimensions to match the fabric size. Proper file preparation is crucial for achieving high-quality DTF prints.

What is the best fabric compatibility for DTF transfers?

The best fabric compatibility for DTF transfers generally includes those with a higher polyester content, as they provide better adhesion. It’s important to avoid high cotton fabrics and textured surfaces, which may lead to poor transfer results.

What are the essential DTF application techniques I should follow?

Essential DTF application techniques include using a heat press at the correct temperature and pressure, and adhering to the recommended timing for the transfer. Following these techniques helps prevent issues such as peeling and fading of DTF prints.

How should I care for DTF prints after printing?

To maintain DTF prints, allow them to cure fully before washing. Follow washing instructions by laundering inside out in cold water, avoiding bleach and fabric softeners. Air drying is preferred to extend the life of your DTF designs.

What maintenance should I perform on my DTF printer?

Regular maintenance for your DTF printer includes cleaning the nozzles to prevent clogs, and ensuring that the printing software is updated. Consistent maintenance helps achieve reliable print quality and prevents dissatisfaction with your DTF transfers.

| Mistake | Consequences | Tips for Avoidance |

|---|---|---|

| Neglecting Proper File Preparation | Blurry or pixelated prints | Ensure images are 300 DPI and converted to CMYK. |

| Using Incompatible Fabrics | Poor adhesion and damaged designs | Choose fabrics with higher polyester content and smooth surfaces. |

| Improper Application Techniques | Peeling or fading transfers | Follow temperature, pressure, and timing guidelines accurately. |

| Overlooking Post-Printing Care | Damaged prints after washing | Allow prints to cure fully and wash inside out. |

| Inadequate Equipment Maintenance | Inconsistent print quality | Regularly clean nozzles and update software. |

Summary

DTF Transfers have revolutionized the printing landscape, providing vibrant and durable designs on a variety of fabrics. By understanding and avoiding common mistakes, such as neglecting proper file preparation, using incompatible materials, and failing to maintain equipment, users can significantly enhance the quality and longevity of their printed designs. Emphasizing careful preparation, meticulous application, and diligent post-care ensures that creations not only look stunning but also stand the test of time in wear and tear. With the right practices in place, DTF transfers can lead to a gratifying printing experience and impressive end results.