DTF transfers, or Direct to Film transfers, have taken the custom apparel industry by storm, redefining how designs are applied to garments. This revolutionary printing technology is known for its ability to produce striking and vibrant graphics that seamlessly adhere to various fabrics, making it an ideal choice for creating high-quality prints. As more businesses seek cost-effective printing solutions that don’t compromise on quality, DTF transfers emerge as a frontrunner, providing versatility and efficiency. With an increasing demand for eco-friendly printing practices, DTF stands out by using water-based inks that are gentler on the environment. In this article, we will explore five compelling reasons why DTF transfers are transforming the landscape of custom apparel, offering businesses innovative ways to meet consumer needs.

Direct to Film transfers—often referred to as DTF printing—have become a preferred method for businesses looking to add personalized designs to clothing and accessories. This advanced printing process harnesses cutting-edge technology to create custom designs that are not only vibrant but also durable across various materials. With its combination of flexibility and rapid production capabilities, businesses can easily navigate small orders while maintaining high standards in print quality. The eco-conscious approach to DTF printing further enhances its appeal, making it a sustainable choice for brands aiming to attract environmentally aware consumers. As we examine the benefits of this transformative printing process, it’s clear that DTF printing is a game-changer in the modern apparel market.

The Rise of Direct to Film (DTF) Transfers

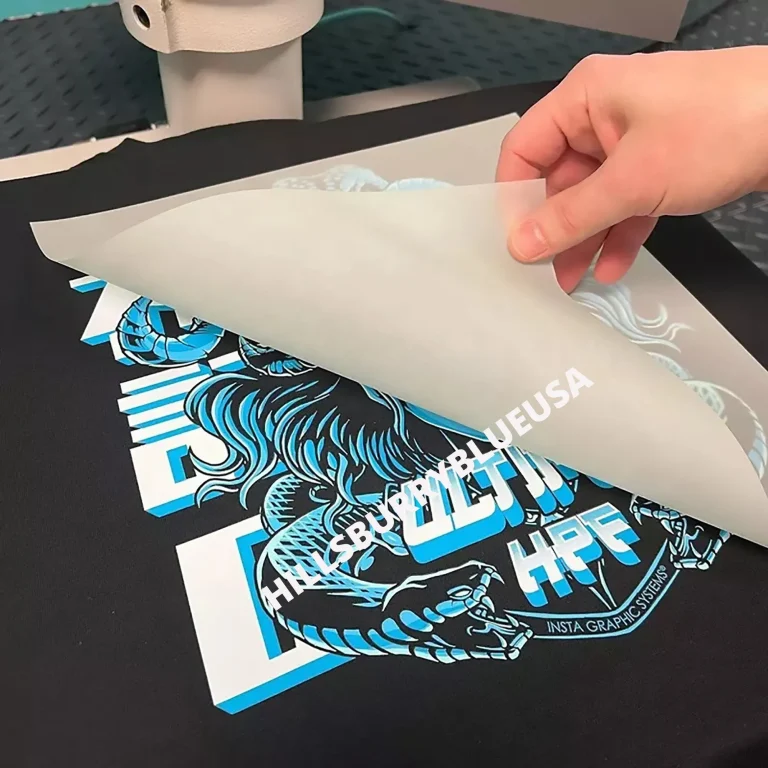

Direct to Film (DTF) transfers are rapidly gaining traction in the custom apparel industry as a revolutionary printing technique that simplifies the process of creating vibrant designs on fabrics. By utilizing unique film technology, DTF allows for highly detailed images to be transferred onto clothing with ease,, which is a significant advantage compared to traditional methods like screen printing. The shift towards DTF is driven by demand for high-quality prints that maintain sharpness and color integrity on various types of textiles, thereby meeting the standards of both businesses and consumers alike.

This printing method not only caters to the aesthetic needs of custom apparel but also addresses the practical side of production. With DTF transfers, businesses can swiftly produce items that resonate with their target market, ensuring they stay ahead of trends. The technology used in DTF transfers ensures consistency and allows for flexibility in design, making them ideal for limited runs or custom orders. As the industry continues to evolve, DTF is set to play a pivotal role in how custom designs are brought to life.

High-Quality Prints That Impress

A defining characteristic of DTF transfers is their capability to deliver superior quality prints. The innovative technology involved in DTF printing allows for a high level of detail and vibrant color that is often unmatched by conventional printing techniques. Unlike direct-to-garment (DTG) printing, DTF transfers can maintain integrity and vibrance across various materials, giving businesses the ability to cater to a wide range of customer preferences. Whether it’s intricate logos, photographs, or colorful patterns, the vividness achieved through DTF transfers sets a high standard for custom apparel.

Moreover, this printing method supports a vast range of color palettes, allowing designers to work creatively without worrying about practical limitations. High-quality prints achieved through DTF methods ensure that every shirt, hoodie, or bag coming off the production line is a testament to the craftsmanship and artistic intention behind it. This level of quality is essential for brands that aim to establish a strong market presence and foster customer loyalty through visually appealing apparel.

Versatility of DTF Transfers Across Fabrics

One of the most compelling features of DTF transfers is their incredible versatility, which allows them to be applied seamlessly to an extensive array of fabrics. From cotton to polyester and everything in between, DTF technology accommodates various materials without compromising print quality. This adaptability means that businesses can diversify their product offerings, creating custom apparel that meets different consumer needs and preferences, whether for fashion, workwear, or special events.

Additionally, the versatility of DTF transfers means that they can be used for both light and dark fabrics, expanding the potential applications even further. This capability eliminates the need for different ink types or complicated setups for varying textiles, thus simplifying the printing process and reducing costs. With DTF transfers, companies can confidently explore new markets and trends, knowing that they have the technology to deliver high-quality results across different fabric types.

Cost-Effective Printing Solutions for Small Businesses

For small businesses, the cost of production can often determine their growth and sustainability. DTF transfers present a cost-effective solution that allows for small runs without the high initial expenses typically associated with traditional printing methods. Unlike screen printing, which usually necessitates substantial setup fees and minimum order sizes, DTF technology offers reprieve from these constraints, giving entrepreneurs the flexibility to produce custom apparel on demand.

This flexibility is particularly advantageous for businesses that thrive on personalized merchandise and short-run orders. DTF enables creators and designers to offer their customers customized products while maintaining profitability. As the demand for unique and personalized items grows, adopting DTF transfers can provide the financial viability and competitive edge businesses need in today’s market.

Rapid Turnaround Times with DTF Printing

In today’s fast-paced retail environment, the ability to deliver products quickly can be the difference between success and failure. DTF transfers excel in providing rapid turnaround times, enabling businesses to fulfill customer orders without delay. The efficient nature of the DTF printing process not only streamlines production but also helps meet the growing demand for quick service, particularly in the custom apparel sector where trends can shift swiftly.

Moreover, the quick production capability associated with DTF technology allows businesses to manage their workflow efficiently, responding adaptively to customer requests. Whether fulfilling large orders for events or addressing urgent last-minute requests, DTF transfers equip businesses with the agility required to remain competitive in a saturated market. This rapid response ultimately contributes to customer satisfaction, fostering long-lasting loyalty.

Eco-Friendly Practices in Apparel Printing

As consumers become increasingly aware of environmental issues, the demand for sustainable manufacturing practices has risen. DTF printing offers an eco-friendly alternative to traditional printing methods due to its use of water-based inks, which have a significantly lower environmental impact than solvent-based options. By incorporating DTF transfers into their production processes, businesses can minimize their carbon footprint while still delivering high-quality apparel.

Adopting eco-friendly practices not only enhances a company’s reputation but also positions it favorably in the eyes of consumers who prioritize sustainability. Companies that embrace DTF transfers signal their commitment to environmental responsibility, which can be a powerful selling point in a market that increasingly values sustainability. Therefore, integrating DTF printing into business operations aligns with broader trends in consumer behavior, promoting a greener future for the apparel industry.

Frequently Asked Questions

What are DTF transfers and how do they compare to other printing methods?

DTF transfers, or Direct to Film transfers, are a revolutionary method for printing custom apparel. They utilize advanced techniques to produce high-quality prints with vibrant colors, surpassing traditional methods like screen printing and DTG. DTF offers intricate design capabilities, making it ideal for detailed artwork on various fabrics.

What types of materials can DTF transfers be used on?

One of the significant advantages of DTF transfers is their versatility. They can be applied to a wide range of materials, including cotton, polyester, and mixed fabric blends. This compatibility means businesses can create custom apparel that meets diverse customer needs, whether on light or dark fabrics.

How are DTF transfers cost-effective for small businesses?

DTF transfers provide a cost-effective solution for small businesses by eliminating expensive setup costs and minimum order quantities associated with traditional printing methods. This allows for affordable small-batch production, making DTF an attractive option for personalized custom apparel orders.

What is the turnaround time like for DTF transfers?

DTF transfers are known for their rapid turnaround times. The efficient printing process enables businesses to quickly fulfill orders while maintaining high print quality. This speed is essential in meeting customer demands, especially for last-minute custom apparel requests.

Are DTF transfers an eco-friendly printing option?

Yes, DTF transfers are considered more eco-friendly than traditional printing techniques. They primarily use water-based inks, which reduce environmental impact compared to solvent-based inks. Businesses adopting DTF can enhance their sustainability efforts while providing high-quality custom apparel.

Why should businesses consider DTF transfers for custom apparel production?

Businesses should consider DTF transfers for their ability to produce high-quality prints, versatility in material compatibility, cost-effectiveness for small runs, rapid turnaround times, and eco-friendly practices. These factors combined make DTF a modern solution to meet the diverse demands of the custom apparel market.

| Key Features of DTF Transfers | Description | Benefits | |

|---|---|---|---|

| High-Quality Prints | Produces vibrant, sharp designs that can outperform traditional methods. | ||

| Versatility and Material Compatibility | Works on a variety of fabrics, including cotton and polyester, without quality loss. | ||

| Cost-Effectiveness for Small Runs | Ideal for small businesses with low setup costs and flexibility for custom orders. | ||

| Rapid Turnaround Times | Allows for quick fulfillment of orders while maintaining high-quality standards. | ||

| Eco-Friendly Practices | Utilizes water-based inks, reducing environmental impact and appealing to eco-conscious consumers. | ||

Summary

DTF transfers are redefining the landscape of custom apparel printing. These high-quality prints offer exceptional versatility, making them suitable for various fabric types. Moreover, DTF transfers provide cost-effective solutions for small production runs, enabling businesses to cater to personalized orders efficiently. With rapid turnaround times, companies can meet tight deadlines without compromising quality. Finally, the eco-friendly nature of DTF printing aligns with the rising demand for sustainable practices in the fashion industry. Overall, embracing DTF transfers not only elevates product offerings but also positions businesses as leaders in sustainable custom apparel.