DTF transfers, or Direct-to-Film technology, are redefining the landscape of the custom printing industry. This innovative printing method allows for high-quality and versatile design applications, making it a preferred choice for manufacturers and entrepreneurs alike. As we delve into the **benefits of DTF**, you’ll discover how its efficiency and cost-effectiveness can transform your printing business. With DTF printing, vibrant colors and intricate details become easily attainable, all while utilizing eco-friendly printing practices that resonate with today’s conscious consumers. Join us as we explore five compelling reasons why DTF transfers are not just a trend, but the future of custom printing.

Also known as Direct-to-Film (DTF) printing, this groundbreaking approach to custom apparel and promotional item creation has gained significant traction in recent years. By employing advanced direct-to-film technology, businesses can achieve vibrant designs that cater to a variety of materials and preferences. This article will highlight the numerous advantages that come with using DTF transfers, enhancing your understanding of a technique that could revolutionize your company’s printing capabilities. The seamless integration of high-quality outputs with sustainable practices offers a holistic solution for businesses looking to thrive in the modern marketplace. Discover the potential of this innovative printing method and why it’s becoming essential for brands in the custom prints sector.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology has emerged as a revolutionary method in the custom printing landscape. By utilizing a unique film, this approach allows for vibrant, high-resolution prints that can be transferred onto a variety of fabrics. Unlike traditional techniques such as screen printing, which demands extensive setups and labor, DTF printing simplifies the process, enabling manufacturers to produce intricate designs much more efficiently. This method not only enhances color fidelity but also guarantees the longevity of the prints, making it an ideal choice for businesses aiming for quality and durability.

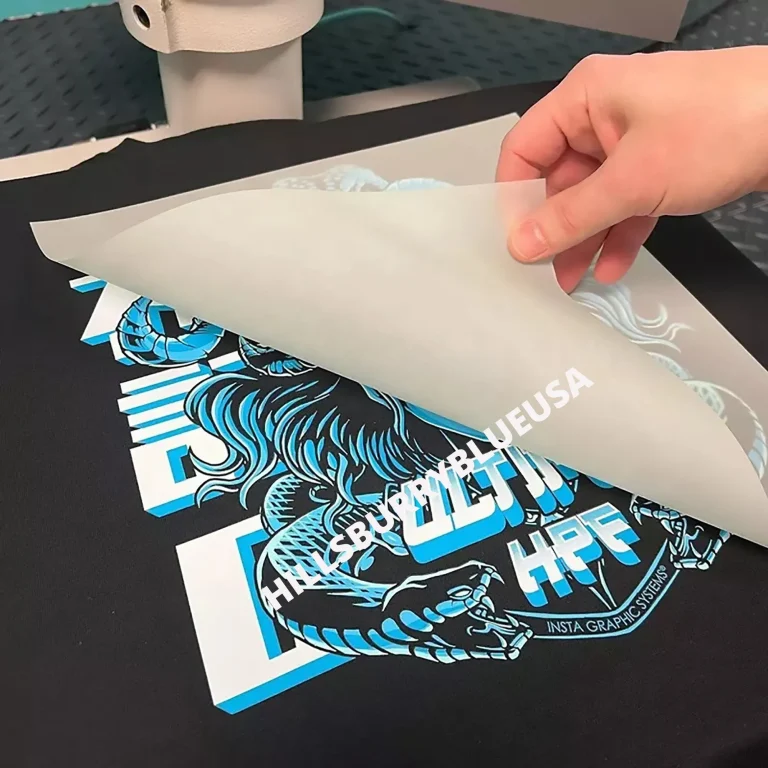

Furthermore, the mechanics of DTF printing involve printing a design onto a special film using water-based inks. This film is then applied to the fabric using heat and pressure, effectively embedding the design into the fibers. The versatility of DTF technology allows it to function seamlessly across different materials, including cotton, polyester, and blends. As such, businesses are now offered the opportunity to cater to diverse consumer preferences, whether for custom apparel, promotional items, or unique, one-off designs.

The Benefits of DTF Transfers in Custom Printing

DTF transfers offer numerous benefits that set them apart from traditional printing methods. One of the most significant advantages is their high-quality output. The printing process captures intricate details and produces vibrant colors that stand out, even on darker fabrics. This quality enables businesses to create visually appealing products that attract consumers and enhance brand identity. Additionally, DTF prints are known for their durability – they can withstand multiple washes without fading or peeling, which assures customers of long-lasting apparel.

Moreover, DTF transfers significantly reduce production times, allowing businesses to meet tight deadlines more efficiently. This capability is crucial in a market where consumers expect quick turnarounds for personalized products. The flexibility of DTF also accommodates various order sizes, ranging from bulk productions to smaller, on-demand runs, making it a practical choice for startups and established brands alike.

Versatility of DTF Transfers Across Fabric Types

One of the standout features of DTF transfers is their remarkable versatility across fabric types. Unlike some traditional printing methods that are restricted to specific materials, DTF printing can be applied to an extensive range of textiles, including cotton, polyester, and blends. This adaptability allows businesses to tap into various markets and customer preferences, thereby expanding their product offerings and enhancing customer satisfaction.

Additionally, as fashion trends evolve and consumers increasingly seek unique designs, DTF technology affords creatives the freedom to experiment with vibrant colors and complex patterns. Whether it’s for sportswear, promotional garments, or high-fashion apparel, the ability to print on diverse materials without compromising quality positions DTF transfers as a go-to solution for modern custom printing needs.

Speed and Efficiency in DTF Printing

In the fast-paced world of custom printing, speed and efficiency are paramount, and DTF transfers excel in this regard. The process involved in DTF printing allows for quick turnaround times compared to traditional methods, which often require meticulous setup and lengthy production cycles. Once a design is finalized, applying the transfer is swift and straightforward, enabling businesses to fulfill orders rapidly.

This efficiency not only meets customer demands for faster delivery but also enhances operational efficiency for companies, especially those engaged in e-commerce. With DTF printing, businesses can easily manage varying order quantities, fulfilling both large-scale and small custom requests without incurring hefty additional costs, which ultimately benefits the bottom line.

Cost-Effectiveness of DTF Transfers

Cost-effectiveness is a critical consideration for small businesses and startups in the custom printing industry, and DTF transfers provide an economically viable solution. Compared to traditional printing methods like Direct-to-Garment (DTG) printing, the initial investment in DTF technology is lower. The materials used, which often consist of affordable films and water-based inks, further contribute to reduced production costs.

This financial feasibility enables emerging brands to explore custom apparel without the heavy financial burdens typically associated with larger operations. By employing DTF technology, businesses can optimize their production strategies, facilitating sustainable growth while remaining competitive in a crowded market.

Eco-Friendly Practices in DTF Printing

As the demand for environmentally responsible practices increases, DTF printing technology has adapted to meet these consumer expectations through eco-friendly innovations. Many manufacturers embrace water-based inks in their DTF processes, significantly reducing harmful chemical usage and minimizing environmental impact. This shift not only preserves print quality but also aligns with the growing consumer base that values sustainability.

By incorporating eco-friendly methods, businesses can build a positive reputation among environmentally conscious buyers. This shift towards sustainability in DTF printing assures customers that they are making responsible purchases, ultimately contributing to a more sustainable future in the custom printing industry.

Frequently Asked Questions

What are DTF transfers and how do they work in custom printing?

DTF transfers, or Direct-to-Film transfers, are a modern technique used in custom printing that involves printing designs onto a special film, which is then transferred onto various materials using heat. This process allows for vibrant colors and high-quality prints, making it suitable for a wide range of products from apparel to promotional items.

What are the benefits of DTF printing compared to traditional printing methods?

The benefits of DTF printing over traditional methods include superior color vibrancy, the ability to print on a variety of materials, faster turnaround times, and cost-effectiveness. Furthermore, DTF technology often uses eco-friendly practices, appealing to environmentally-conscious consumers.

Can DTF printing be used on different fabric types?

Yes, DTF printing is highly versatile and can be used on various fabric types, including cotton, polyester, and blends. This versatility allows businesses to create custom designs on a wide range of products, catering to diverse customer preferences.

How does DTF transfer technology support small businesses in the custom printing industry?

DTF transfer technology supports small businesses by providing a cost-effective solution that allows for smaller production runs without sacrificing quality. This flexibility enables emerging brands to compete effectively in the custom printing market without the financial burdens typically associated with larger-scale operations.

What makes DTF transfers an eco-friendly printing option?

DTF transfers are considered eco-friendly due to the adoption of water-based inks and sustainable practices. This environmentally-conscious approach minimizes the ecological impact of the printing process, aligning with consumer preferences for greener products.

How quickly can orders be fulfilled using DTF transfers?

Orders can be fulfilled quickly using DTF transfers, as the transfer process is significantly faster than traditional printing methods. Businesses can finalize designs and produce prints rapidly, enhancing customer satisfaction and encouraging repeat business in the competitive custom printing landscape.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers are revolutionizing the custom printing industry through efficiency and versatility. |

| High Quality and Vibrancy | Produces high-resolution images with vibrant colors, ideal for detailed designs and durability after multiple washes. |

| Versatility Across Materials | Can print on various fabrics including cotton, polyester, and blends, accommodating diverse design needs. |

| Fast Turnaround Time | Quick application process allows faster fulfillment of orders, essential for e-commerce and on-demand printing. |

| Cost-Effectiveness | Less expensive than other methods, suitable for small businesses with limited budgets and small quantities. |

| Environmentally Friendly Options | Utilizes water-based inks reducing environmental impact, aligning with consumer demands for sustainable practices. |

Summary

DTF transfers are quickly becoming the leading choice for businesses in the custom printing industry. With their ability to deliver high-quality outputs, versatility across a range of materials, and rapid production times, DTF technology stands out as a favorable solution. Furthermore, the cost-effectiveness and dedication to sustainable practices make DTF printing an appealing option for environmentally conscious consumers. As more companies embrace DTF transfers, it is evident that this method is not only shaping the present landscape of custom printing but also paving the way for future innovations, ensuring businesses remain competitive and responsive to market trends.