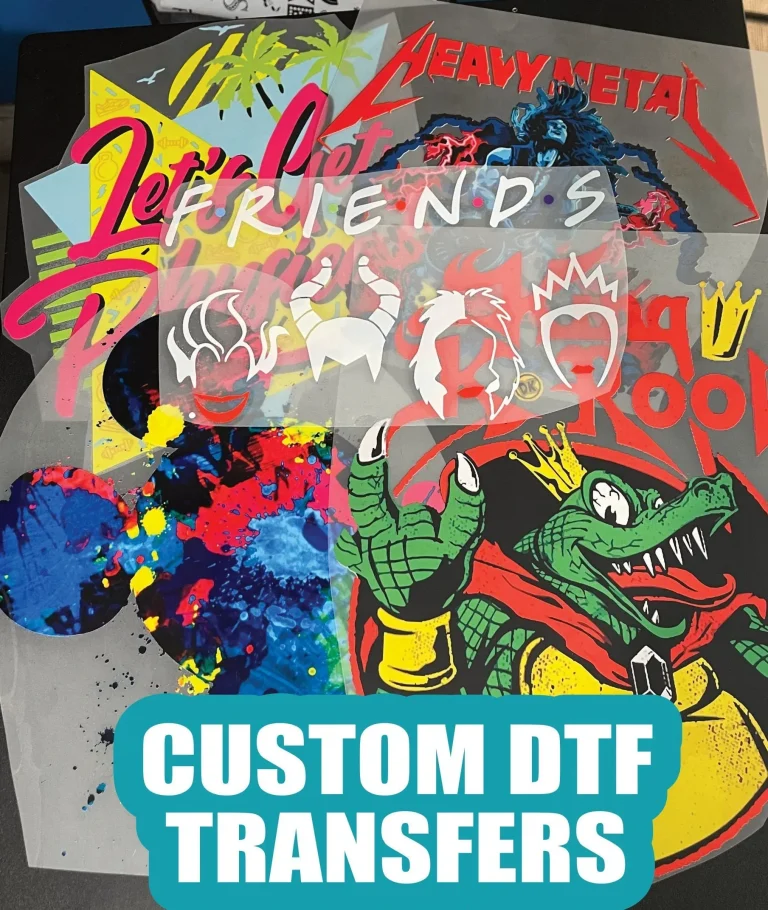

DTF transfers, or Direct to Film transfers, have emerged as a revolutionary method in the garment printing industry, ranked highly for their ease of use and impressive output quality. Whether you’re a seasoned printing expert or a newcomer exploring beginner DTF printing, this technique offers a seamless way to create vibrant and durable designs on a variety of fabrics. The advantages of DTF transfers include versatility in fabric choice and cost-effective setup, making it an attractive option for all skill levels. If you’re eager to learn how to master DTF transfers, understanding the fundamental DTF printing techniques can pave the way for your creative endeavors. Plus, with the rise of eco-friendly DTF printing methods, manufacturers are increasingly embracing sustainable practices without compromising on quality.

In the realm of garment decoration, various techniques have gained popularity, and one such innovative method is known as transfer printing directly onto film. This approach simplifies the complex process typically associated with traditional fabric printing, offering a user-friendly option for those just starting. The remarkable benefits of this technique include its adaptability to numerous materials and the ability to produce eye-catching, long-lasting prints. As you delve into the world of print transfers, you’ll also discover resources on beginner-friendly guides, making it easier to engage with the latest trends and eco-conscious practices in the industry. Exploring these creative avenues can inspire both hobbyists and budding entrepreneurs to dive into this exciting landscape.

What is DTF Printing?

Direct to Film (DTF) printing is an innovative method that has transformed the landscape of garment printing. At its core, DTF printing utilizes specialized films to create vibrant designs that are transferred onto various fabrics through heat and pressure application. This technique stands out for its simplicity and effectiveness, positioning it as an appealing option even for those just starting in the world of garment decoration. By understanding the foundational elements of DTF printing, newcomers can effectively leverage this technique for their creative projects.

Additionally, the flexibility inherent in DTF printing makes it well-suited for diverse applications. Unlike traditional methods, such as screen printing, DTF allows for intricate designs and detailed artwork to be applied on a variety of fabric types including cotton, polyester, and blended materials. This versatility opens up opportunities for printers to experiment with different substrates and create unique fashion items or promotional apparel. As more enthusiasts seek to master DTF transfers, adopting this method can lead to exciting creative possibilities.

Advantages of DTF Transfers

DTF transfers offer numerous advantages that make them a favored choice among garment printing methods. One significant benefit is the ability to produce vivid, high-quality prints that remain bright and durable over time, even after multiple washes. This quality is particularly important for businesses requiring a professional appearance for their merchandise. The bright colors and fine details achievable with DTF printing ensure that designs stand out, which is essential for creating eye-catching apparel.

Moreover, DTF transfers are a cost-effective solution for those looking to start a printing venture. The initial investment required for a DTF printing setup is relatively low when compared to other methods, such as screen printing, which often involves steep equipment costs and lengthy setup times. For beginners, this means they can dive into DTF printing with less financial risk while still achieving high-quality output. Combining affordability with high-quality results makes DTF a strong contender for anyone considering entering the custom garment market.

Essential Equipment for DTF Printing

Before embarking on the DTF printing journey, it’s crucial to familiarize oneself with the essential equipment required to achieve optimal results. At the core of any DTF printing operation is the DTF printer, which is specialized to handle particular inks and films. Investing in a reliable DTF printer often determines the quality of the final product, making it a critical choice for both beginners and seasoned professionals alike.

In addition to the printer, other equipment such as transfer films and powder adhesives are vital components of the DTF ecosystem. The transfer film acts as the medium for the design, while powder adhesive is necessary for ensuring that the print adheres properly during the transfer process. Furthermore, a high-quality heat press is indispensable for applying the correct amount of heat and pressure, which influences the final adhesion and appearance of the print. Understanding these components and investing wisely in them creates a solid foundation for successful DTF printing.

Step-by-Step Process of DTF Transfers

Mastering DTF transfers involves a systematic step-by-step process that ensures successful transfer of designs onto fabrics. First, it begins with creating a design using graphic design software. Whether the design is intricate or simplistic, the digital artwork sets the tone for the entire print. Following this, printing the design onto DTF transfer film is crucial. It’s essential to utilize high-quality settings on the printer to guarantee the best possible results, as poor print quality can lead to unsatisfactory outcomes.

After printing, the application of powder adhesive is the next critical step that cannot be overlooked. This powder serves as the binding agent that helps the design firmly adhere to the fabric during pressing. Once the powder is applied, it must be heat cured to bond it effectively. The final stages of positioning the film on the fabric and pressing it using a heat press are what eventually reveal the vivid design through the careful peeling of the film after cooling. Following these steps meticulously allows beginners to achieve professional-looking results right from the outset.

Common Challenges Faced by Beginners in DTF Printing

While DTF printing is designed to be accessible, beginners may face a range of challenges that can hinder their initial successes. One common issue is achieving clarity in prints. Newcomers may struggle with settings not being optimized for their specific printer or film, which can lead to unclear or inconsistent results. Adjusting printer settings, experimenting with different films, and ensuring high standards of cleanliness during the printing process can mitigate these challenges and significantly improve print quality.

Another prevalent issue is related to heat settings during the transfer process. If the temperature or pressure applied during pressing is not accurate, it can affect how well the ink adheres to the garment, leading to peeling or fading designs. Therefore, not only is it essential to follow recommended guidelines, but also to test various settings on different materials to find the ideal combinations for successful transfers. By being mindful of these potential hurdles, beginners can navigate DTF printing with confidence and improve their overall craft skills.

Sustainable Practices in DTF Printing

As the printing industry evolves, sustainability has become a significant focus, and DTF printing is no exception. The rise of eco-friendly DTF inks is a notable trend, as manufacturers begin to prioritize water-based inks that reduce harmful emissions compared to solvent-based alternatives. This shift not only aligns DTF printing with contemporary environmental standards but also appeals to conscious consumers who are increasingly looking for sustainable apparel options.

This trend towards sustainability extends further with advancements in printing technology, which aim to enhance the efficiency and reduce waste associated with DTF printing processes. Utilizing more efficient waste recycling methods and adopting better fabric printing techniques directly contribute to a lower carbon footprint. For beginners looking to make an impact, embracing sustainable practices within their DTF printing can set them apart in a crowded market, attracting an audience that values environmentally responsible choices.

Frequently Asked Questions

What are the advantages of DTF transfers for beginners?

DTF transfers offer numerous advantages, especially for beginners in the printing industry. They are versatile, allowing you to print on various fabrics such as cotton and polyester. DTF printing also produces vibrant colors that remain bright even after multiple washes. Furthermore, the cost-effective setup makes it an accessible option for newcomers looking to explore garment printing.

How do I start beginner DTF printing?

To begin your journey in DTF printing, you’ll need the right equipment, including a DTF printer, specialized transfer film, and a heat press. Start by creating a design using graphic design software, print it on the transfer film, apply powder adhesive, and then use the heat press to transfer the image onto your fabric. Following these steps ensures a smooth introduction to beginner DTF printing.

What are some essential DTF printing techniques to master?

Key DTF printing techniques include optimizing printer settings for clarity, properly applying powder adhesive to ensure strong ink adhesion, and mastering the heat press application for effective transfers. Each of these techniques is crucial to achieving high-quality results in your DTF transfers.

Why should I choose eco-friendly DTF printing options?

Choosing eco-friendly DTF printing options, such as water-based inks, aligns your printing practice with environmentally responsible principles. Eco-friendly DTF printing reduces harmful chemical waste and supports sustainable practices while still delivering high-quality outputs.

How can I improve print clarity in DTF transfers?

To enhance print clarity in DTF transfers, adjust your printer settings to high-quality modes, ensure you’re using the right type of transfer film, and perform regular maintenance on your printer. Testing with different fabric types can also help identify the best combinations for achieving clear prints.

What resources can help me learn how to master DTF transfers?

To master DTF transfers, utilize online tutorials on platforms like YouTube, enroll in specialized courses that focus on different DTF printing aspects, and engage with community forums where you can share experiences and gather tips from fellow DTF enthusiasts.

| Key Point | Description |

|---|---|

| Overview of DTF Transfers | DTF transfers allow vibrant designs to be printed onto fabrics, making them popular for both beginners and professionals. |

| Understanding DTF Printing | This method involves printing designs on a film and transferring them to fabrics using heat and pressure, streamlining the printing process. |

| Equipment Needed | Essential equipment includes a DTF printer, transfer film, powder adhesive, and a heat press. |

| Step-by-Step Process | Create a design, print it, apply adhesive, transfer, and finally peel off the film to reveal the final design. |

| Advantages of DTF Transfers | The versatility to print on various fabrics and the cost-effective setup are major benefits of this technique. |

| Common Challenges | New users may face clarity issues, improper pressing temperatures, and ink adhesion problems. |

| Resources for Learning | Online tutorials, courses, and community forums are available for beginners to master DTF printing. |

| Recent Trends | There is a growing trend towards eco-friendly inks and new technologies that improve quality and efficiency. |

| Community Support | Engaging with online forums and social media groups can enhance the learning experience for DTF printing. |

Summary

DTF Transfers are revolutionizing the garment printing industry by allowing individuals to create stunning designs with ease. This innovative printing method stands out not only for its efficiency and high-quality results but also for its versatility across different fabric types. Whether you’re a seasoned professional or a curious beginner, DTF Transfers offer a gateway to unleash your creativity with just a minimal initial investment in equipment. The landscape of DTF printing is expansive, expanding further through advancements in technology and a supportive community, making it more accessible than ever. If you’re looking to embark on a new creative journey or start a business, mastering DTF Transfers could be your perfect avenue.