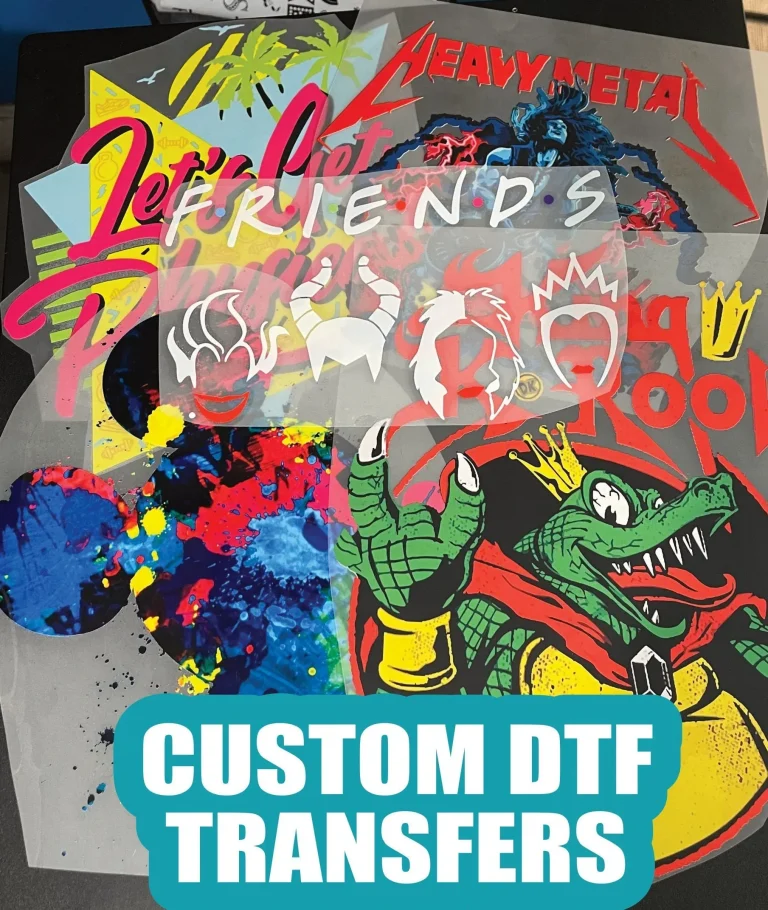

DTF transfers, short for Direct-to-Film transfers, have revolutionized the landscape of custom apparel printing, making it easier than ever to produce stunning designs on fabric. This innovative DTF printing process utilizes advanced technology to create vibrant and durable prints that can be applied to a wide variety of materials including cotton and polyester. One of the standout DTF transfer advantages is the ability to achieve intricate details and bright colors, which cater to both small businesses and DIY enthusiasts alike. As more individuals venture into this exciting domain, the methodology behind DTF transfers offers an accessible way for beginners to make their mark in the custom printing industry. Stay tuned as we explore the nuances of this method and what newcomers need to know to get started with DTF.

In the realm of contemporary printing techniques, Direct-to-Film transfers have emerged as a cutting-edge solution for anyone looking to engage in custom fabric printing. Often referred to as DTF printing, this innovative approach allows users to apply high-quality, detailed designs onto various surfaces with remarkable ease. The DTF transfer method stands out not only for its vibrant visuals but also for its efficacy in creating durable prints that withstand the test of time. Combined with its user-friendly process, DTF has become a go-to option for those eager to explore the world of custom design. As we delve deeper into the intricacies of this printing technique, you will discover essential tips and insights that will empower your DTF printing journey.

Understanding the DTF Printing Process

The DTF printing process stands out for its innovative use of specialized films and distinct adhesives, setting it apart from traditional printing methods. Initially, high-resolution designs are printed onto a specially formulated film in reverse with a DTF printer. This unique technique allows creators to achieve vibrant colors and intricate details that are essential for custom designs. The application of adhesive powder while the ink is wet ensures optimal bonding during the heat transfer stage, a key step that guarantees the longevity of the print. This meticulous process unlocks the potential for stunning visuals, making DTF transfers a popular choice for fashion designers and hobbyists alike.

Once the print is completed, the film undergoes a curing process where heat solidifies the adhesive, preparing it for application. The subsequent transfer stage employs a heat press to bond the design securely to the chosen substrate, which can range from cotton to polyester. Understanding this detailed workflow is crucial for beginners, as each step contributes significantly to the overall quality of the final product. Mastering the DTF printing process opens up a world of creative possibilities in the custom apparel market, allowing for personalized creations that resonate with consumers.

Key Advantages of Using DTF Transfers

DTF transfers offer numerous advantages that appeal to both small business owners and DIY enthusiasts looking to enter the market of custom apparel printing. One of the standout benefits is the high detail that DTF prints can achieve. This technology produces bright, vibrant colors and intricate designs that hold well on various fabric types. This level of quality is vital for brands seeking to make an impact with their apparel, as customers are increasingly drawn to unique, high-quality designs that stand out in a crowded marketplace.

Moreover, the versatility of DTF transfers cannot be overlooked. This method is compatible with numerous fabric types, including cotton blends and synthetic materials, making it a suitable choice for an array of projects. The durability of DTF prints is another significant benefit; they withstand multiple washes and maintain their appearance over time. This makes DTF printing a reliable choice for creating long-lasting apparel items that do not fade or deteriorate quickly, thus enhancing customer satisfaction and long-term relationships.

Essential Equipment for DTF Printing

The right equipment is crucial when venturing into DTF printing, especially if you aim for high-quality results. A DTF printer specifically designed for this process is fundamental; these printers utilize modified inkjet technology and specialized inks tailored for vibrant and long-lasting prints. Investing in an appropriately calibrated DTF printer can significantly enhance your output, providing clarity and color depth that may not be achievable with standard printers.

Beyond the printer, you will need DTF inks that guarantee durability and vibrancy, along with high-quality transfer films that facilitate successful designs. The proper heat press is equally important—it is essential for applying consistent and even heat to ensure that the design adheres properly to the fabric. Collectively, assembling the right tools can make or break your endeavors in DTF printing, paving the way for successful projects and satisfied customers.

Tips for Successful DTF Transfers

Achieving remarkable results in DTF printing requires knowledge and practice. One of the most effective tips for success is conducting test prints before finalizing any project. Testing allows you to experiment with different fabrics and adjust settings on your heat press to achieve optimal results. Additionally, calibrating the temperature settings is crucial; improper heat levels can lead to poor adhesion or damage to the fabric, ruining the design.

Furthermore, don’t hesitate to learn from the community. There are numerous online resources and forums dedicated to DTF printing where you can gain valuable insights from experienced printers. Engaging with these platforms can help you stay updated on best practices and troubleshooting techniques—ideal for beginners wanting to refine their skills and enhance their craft.

Getting Started with DTF for Beginners

Starting out in DTF printing as a beginner may seem daunting, but the process can be simplified with the right preparation and mindset. It is advisable to invest time in familiarizing yourself with the equipment needed, which includes understanding how to operate your DTF printer and the optimal settings for your designs. Additionally, learning about the types of fabrics suitable for DTF transfers will enable you to select the best materials for your projects.

Moreover, consider joining beginner courses or workshops that focus specifically on DTF printing. These programs can provide you with hands-on experience and the necessary knowledge to navigate the learning curve efficiently. By actively seeking out opportunities to learn and experiment, you will quickly gain confidence in producing stunning custom designs.

Recent Trends in DTF Printing Technology

The landscape of DTF printing is constantly evolving, with recent developments bringing exciting innovations to the forefront. As more individuals and businesses recognize the advantages of DTF technology, the demand for cost-effective printing solutions continues to rise. This growth has led to the introduction of more user-friendly equipment and software solutions, making DTF printing accessible to a broader audience.

Additionally, advancements in ink formulations and transfer films have significantly improved print quality and durability. These developments mean that new users can achieve professional-grade results right from the beginning of their journey, further popularizing DTF printing. Keeping an eye on industry trends and advancements is essential for anyone looking to establish themselves in the custom apparel market.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves several steps to create high-quality DTF transfers. First, a design is printed in reverse on a specialized film using a DTF printer. Next, a hot adhesive powder is applied while the ink is wet. The design is then cured with heat to solidify the adhesive, and finally, it is transferred to the fabric using a heat press, ensuring a vibrant and durable print.

What are the advantages of using DTF transfers for custom apparel printing?

DTF transfers offer numerous advantages for custom apparel printing, including high detail with vibrant colors, versatility across various fabric types, and excellent durability that withstands washing and wear. They also provide a straightforward printing process, making them ideal for beginners and small businesses entering the custom printing market.

What equipment is required to start DTF printing?

To start DTF printing, you need specific equipment including a DTF printer, specialized DTF inks, transfer films for printing designs, and a heat press to apply the transfers to fabrics. Investing in quality equipment is crucial for achieving the best results in your DTF transfers.

How can beginners learn about DTF printing and improve their skills?

Beginners can learn about DTF printing by utilizing online resources such as tutorial videos on platforms like YouTube, joining DTF printing forums, and accessing blogs that provide insights and tips. Experimenting with different fabrics and conducting test prints can also enhance your skills in creating effective DTF transfers.

What types of fabrics can DTF transfers be applied to?

DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and various blends. This versatility makes DTF printing a popular choice for creating custom apparel and merchandise across different material types.

How do DTF transfer prints compare to other printing methods?

Compared to other printing methods, DTF transfers excel in quality and durability. They provide brighter colors and finer details than traditional screen prints and can adhere well to multiple fabric types. Additionally, DTF printing is often more affordable and easier to use, making it a favored choice among custom apparel printers.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Direct-to-Film (DTF) transfers are a custom printing method that prints designs onto a specialized film for application on fabrics. |

| DTF Transfer Process | 1. Design Printing: Print design on film in reverse. 2. Adhesive Application: Apply powder adhesive on wet ink. 3. Curing Process: Heat to solidify adhesive. 4. Transfer Application: Heat press to apply design. |

| Advantages of DTF Transfers | High detail, versatility for various fabrics, durability against washing, and simplicity in process. |

| Equipment Needed for DTF Printing | DTF printer, DTF inks, transfer films, heat press. |

| DIY Setup Recommendations | Invest in quality equipment, source high-quality materials, and utilize online learning resources. |

| Tips for Effective DTF Transfers | Conduct test prints, control heat press temperature, and practice on different fabrics. |

Summary

DTF transfers have revolutionized the custom printing industry, providing a versatile and effective solution for creating stunning designs on various fabrics. With their ability to deliver high-quality images that withstand the test of time, DTF transfers are an ideal choice for both beginners and seasoned professionals in the printing field. By understanding the DTF transfer process, investing in the right equipment, and employing best practices, anyone can harness the power of DTF technology to achieve vibrant, impactful results in custom apparel. Whether you’re starting a small business or simply exploring a creative hobby, DTF transfers can open a world of possibilities for your projects.