DTF transfers, or Direct to Film transfers, have emerged as a game-changer in the garment customization scene, offering a unique and innovative method for transferring vibrant designs onto fabric. This cutting-edge process enables anyone, from hobbyists to small business owners, to apply DTF transfers with ease, delivering high-quality, detailed graphics that stand out. In our comprehensive guide, we explore the intricacies of the DTF transfer printing process, providing clear instructions on how to use DTF transfers effectively, even if you’re just starting out. You’ll discover the best practices for preparing your designs and fabric, ensuring that you achieve stunning results every time. Whether you’re looking to personalize clothing or create branded merchandise, this beginner’s guide to DTF transfers is here to set you on the right path.

The art of transferring designs onto garments using innovative methods like Direct to Film printing is becoming increasingly popular in the crafting community. Known for its remarkable ability to produce intricate and eye-catching prints, this technique allows users to effectively transfer their creativity onto various materials. With this beginner’s guide to the DTF transfer process, we will introduce you to the essentials of applying this modern printing technology. By following our detailed steps, you will learn how to prepare your designs, select the right fabric, and benefit from the vibrant outcome DTF transfers can achieve. If you’re new to the world of custom printing, understanding how to utilize these advanced techniques can elevate your projects and help you stand out in a competitive market.

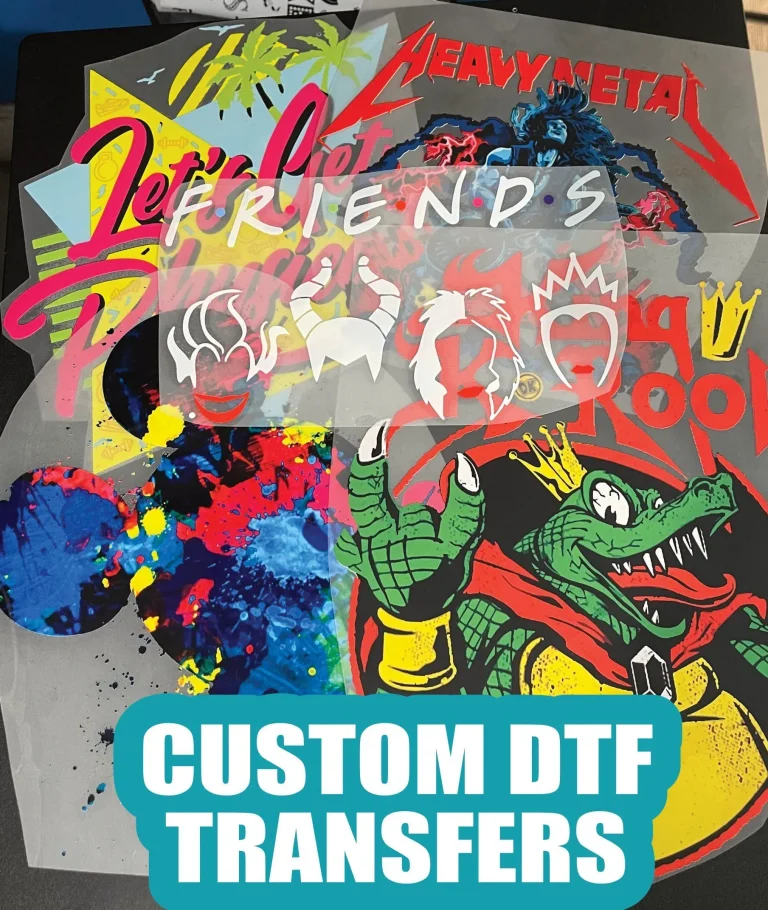

Understanding the Basics of DTF Transfer Printing

DTF transfer printing is a unique method that allows users to create intricate, high-quality designs directly onto fabric. In this technique, the designs are first printed onto a transparent film, which is then heat-pressed onto the selected fabric. This process enables vibrant colors and intricate details to be transferred, opening up a myriad of possibilities for custom clothing and merchandise.

In contrast to traditional methods like screen printing, DTF printing is often more economical for small orders and offers flexibility in terms of fabric choice. Users can apply DTF transfers not just to cotton but a wide range of materials, including blends and synthetic fabrics. Understanding these basics sets the foundation for successfully utilizing DTF technology in your projects.

The Step-by-Step Guide to Applying DTF Transfers

Applying DTF transfers involves multiple steps, including preparing your design, printing, and finally transferring it onto your chosen fabric. Start by ensuring that your graphic design is tailored for DTF printing, maintaining high resolution and suitable color profiles. Once the design is ready, use a dedicated DTF printer to print it onto the transfer film.

After printing, the critical next step is applying a powdered adhesive over the wet ink. This adhesive is what binds the ink to the fabric during the heat application stage. Completing this process correctly will set you on the right path to achieving beautiful, durable prints.

Special Considerations for Beginners in DTF Transfers

For beginners, understanding material compatibility is crucial. Not every fabric reacts the same way to DTF transfers, so test a variety of materials to identify what works best for your designs. Commonly used fabrics like cotton and polyester blends typically yield the best results with DTF transfers.

Additionally, be mindful of the quality of your inks and adhesive powders. Investing in good quality materials not only enhances the vibrancy and durability of your final product but also ensures a smoother application process overall.

Optimizing the DTF Transfer Process for Best Results

Optimization of the DTF transfer process includes ensuring that conditions like humidity and temperature are ideal before printing. Conduct your printing in a climate-controlled area to avoid unexpected issues during application. Pre-heating your fabric also helps eliminate moisture, creating a better surface for the transfer.

The curing process is another area that requires attention. Achieving the correct temperatures and times for curing the adhesive after printing is vital for making sure that the design adheres properly. This step can significantly affect both the durability and the look of your final print.

Recent Trends in DTF Transfer Printing

DTF transfer printing is experiencing exciting trends, notably the move towards sustainability. Many companies are looking to provide eco-friendly inks and materials, ensuring that the environmental impact of garment printing is minimized. This has gained traction among conscious consumers and businesses.

Technological advancements in DTF printers and heat presses are also noteworthy. New devices are being designed to simplify the printing process even further for beginners, with features that enhance usability while maintaining high-quality output. Staying updated with these trends can help businesses stay competitive.

Common Mistakes to Avoid with DTF Transfers

One of the most common mistakes in the DTF transfer process is improperly preparing the fabric. Skipping the crucial step of pre-heating can lead to inconsistent adhesion and a lower quality print. Always ensure that the surface is smooth and moisture-free before applying your transfers.

Additionally, many beginners overlook the importance of peeling the transfer at the right moment. Whether you opt for a hot or cold peel depends on the adhesive used; failing to follow guidelines can result in damaging your design. Paying attention to these details helps in achieving professional-quality results.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing intricate designs on a specialized film that is then transferred to fabric using heat. This method is popular for its ability to produce vibrant prints suitable for various textiles, making it ideal for custom apparel.

How do I apply DTF transfers to my clothing?

To apply DTF transfers, first prepare your design in graphic software, then print the design using a DTF printer. Next, apply powdered adhesive, cure it with heat, prepare your fabric, and press the transfer onto the material. Finally, peel the film and perform a final curing for durability.

What is the beginner’s guide to DTF transfer printing?

A beginner’s guide to DTF transfer printing includes understanding the design preparation, correct printing methods, ensuring proper adhesive curing, and knowing the fabric types suitable for DTF transfers. Following a step-by-step process will help streamline your first attempts.

What are the important steps in the DTF transfer process?

The key steps in the DTF transfer process are: preparing your design, printing with a DTF printer, applying adhesive powder, curing the adhesive, preparing the fabric, pressing the transfer, and performing a final peel and cure to ensure the print adheres securely.

Can I use DTF transfers on any fabric?

Not all fabrics are compatible with DTF transfers. It’s best to test your chosen material first; cotton and polyester blends often work best, while other fabrics may not bond well with the transfer, affecting the print’s quality and durability.

What trends should I know about DTF transfer printing?

Current trends in DTF transfer printing include a push for sustainability with eco-friendly materials and inks, along with advancements in printer technology that make the process easier and more accessible for beginners.

| Step | Description |

|---|---|

| 1. Prepare the Design | Create or select artwork using graphic design software, ensuring optimal resolution and colors for DTF printing. |

| 2. Print the Design | Print using a DTF printer and apply powdered adhesive on wet ink for a strong bond. |

| 3. Cure the Adhesive | Use a heat source to melt the adhesive powder, key for bond strength. Optimal curing temperature: 160-180°C (320-356°F). |

| 4. Prepare the Fabric | Eliminate moisture and wrinkles by pre-heating, and choose suitable fabric types like cotton or polyester blends. |

| 5. Press the Transfer | Position the transfer film on the fabric, cover with a protective sheet, and apply heat and pressure (150-160°C for 10-15 sec). |

| 6. Peel the Transfer | Allow the transfer to cool before carefully peeling off the film, checking adhesion quality. |

| 7. Final Curing | Press with a protective sheet again to enhance durability and adhesion for longevity of the design. |

Summary

DTF transfers are changing the game in garment customization, making it accessible to anyone eager to express their creativity through fabric designs. This step-by-step guide serves as a comprehensive resource for beginners wishing to explore the world of DTF transfers. By meticulously following each step—from preparing your design to the final curing process—you can achieve stunning and durable prints that showcase your unique style. With important tips and recent trends in mind, you can confidently navigate this exciting technology and produce high-quality custom apparel.