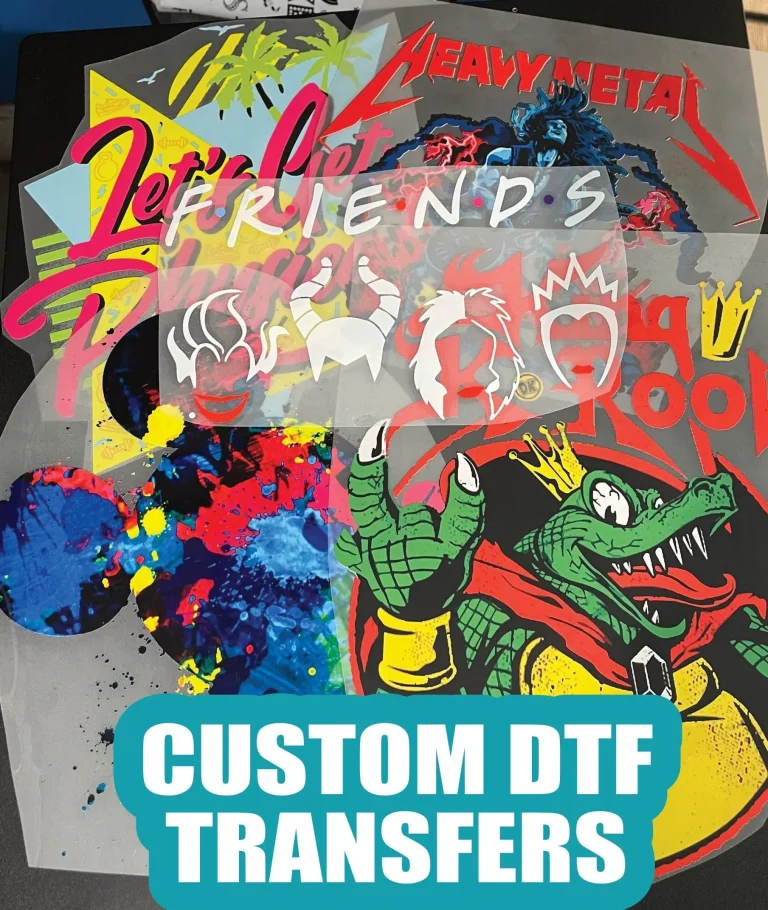

DTF Transfers, or Direct to Film transfers, have revolutionized the world of custom apparel printing by offering exceptional vibrancy and detail in designs. This innovative printing technique allows for intricate patterns to be applied seamlessly onto a variety of fabrics, ensuring that your creations stand out with unmatched quality. One crucial aspect that can significantly impact the overall success of DTF transfers is size optimization; understanding the ideal measurements can enhance print resolution and ensure no loss of detail occurs. From playful graphics on t-shirts to sophisticated logos on professional attire, the versatility of DTF transfers positions them as a top choice among artists and businesses alike. This article explores the critical relationship between DTF transfer size and print quality, providing you with essential information to enhance your printing projects.

Direct to Film printing, often referred to as DTF or film transfer printing, is an emerging technique in the custom apparel sector that captivates designers and consumers alike. This method enables high-resolution prints that can replicate complex designs in stunning detail, making it a formidable choice for various fabric materials. Optimizing DTF transfer sizes not only influences the visual impact of the final product but also enhances durability and quality across different printing applications. As we delve into the nuances of this dynamic printing approach, we will highlight best practices for achieving the highest DTF transfer quality and adapting designs to meet the ever-evolving trends in the apparel industry. Whether you’re an entrepreneur in custom garment production or a creator looking to expand your design portfolio, understanding the intricacies of DTF will undoubtedly enhance your artistry and craftsmanship.

Understanding the Direct to Film Printing Technique

The Direct to Film (DTF) printing technique is revolutionizing the way custom apparel is decorated. This innovative method allows for high-quality transfers that showcase vibrant colors and intricate designs. By printing designs onto a special transfer film, the artwork can be applied to fabrics using heat and pressure, making DTF transfers a versatile solution for various materials, including cotton, polyester, and blends. The ability to create complex imagery in high resolution is a significant advantage, setting DTF apart from traditional methods.

One of the key features of DTF printing is its adaptability to different fabric types. Whether you’re working with lightweight cotton or stretchy polyester blends, DTF transfers can retain their quality without cracking or fading. The process also allows for the production of small quantities, making it an attractive option for custom apparel businesses looking to offer personalized products without the constraints of minimum order quantities.

Frequently Asked Questions

What is the importance of DTF transfer size optimization in custom apparel printing?

DTF transfer size optimization is crucial in custom apparel printing as it directly influences the clarity, detail, and visibility of designs. Properly sized transfers ensure that intricate designs maintain their visual impact, preventing loss of detail on larger prints or looking insignificant on oversized garments.

How does the print resolution affect the quality of DTF transfers?

The print resolution is vital for DTF transfers, with a recommended minimum of 300 DPI for high-quality results. Higher resolutions retain image clarity and prevent pixelation, which is essential for achieving vibrant colors and intricate details in the final printed apparel.

Can DTF transfers be used on any fabric, and how does size play a role?

DTF transfers can be used on a variety of fabrics, including cotton, polyester, and blends. However, the size of the transfer must be adapted according to the fabric type; for example, stretchy materials may require smaller designs to maintain their integrity during movement.

What factors should be considered when determining the best size for DTF transfers?

When determining the best size for DTF transfers, consider factors such as the garment size, the detail level of your design, and the fabric type. Balancing these elements helps in optimizing visibility and maintaining quality across different printing applications.

How do advancements in DTF printing technology impact transfer size adaptability?

Advancements in DTF printing technology allow for greater flexibility in transfer size adaptability. As consumers demand more customized apparel, technology developments enable shorter production runs without compromising quality, accommodating various sizes effectively.

What role does color management play in achieving high-quality DTF transfer results?

Color management is essential in DTF transfers to ensure consistency across different sizes and materials. Implementing accurate color profiles during design helps maintain color fidelity and visual appeal, particularly when adjusting the size of the artwork.

| Key Points | Details |

|---|---|

| What Are DTF Transfers? | DTF transfers involve printing designs on a special film which are then heat-transferred to fabrics, allowing for high-resolution and vibrant colors. |

| Importance of Size in DTF Transfers | The size affects clarity and detail, with larger designs risking loss of intricacy and smaller transfers potentially lacking visual impact. |

| Best Practices for Quality | Use high-resolution images (around 300 DPI) and accurate color management to ensure quality and consistency. |

| Material Considerations | Film and adhesive quality matter; not all films work equally on different fabrics. |

| Market Trends | Customization demand and sustainability trends are shaping the DTF transfer landscape, influencing size and material choices. |

Summary

DTF Transfers are revolutionizing the custom apparel industry by seamlessly combining artistic expression with innovative printing technology. Understanding how size affects the quality and detail of these transfers is crucial in achieving flawless results. As the market evolves, staying abreast of best practices, material choices, and trends not only enhances printing quality but also aligns with consumer expectations for customization and sustainability. By embracing these insights, businesses can elevate their DTF transfer processes, ensuring exceptional product offerings in an increasingly competitive landscape.