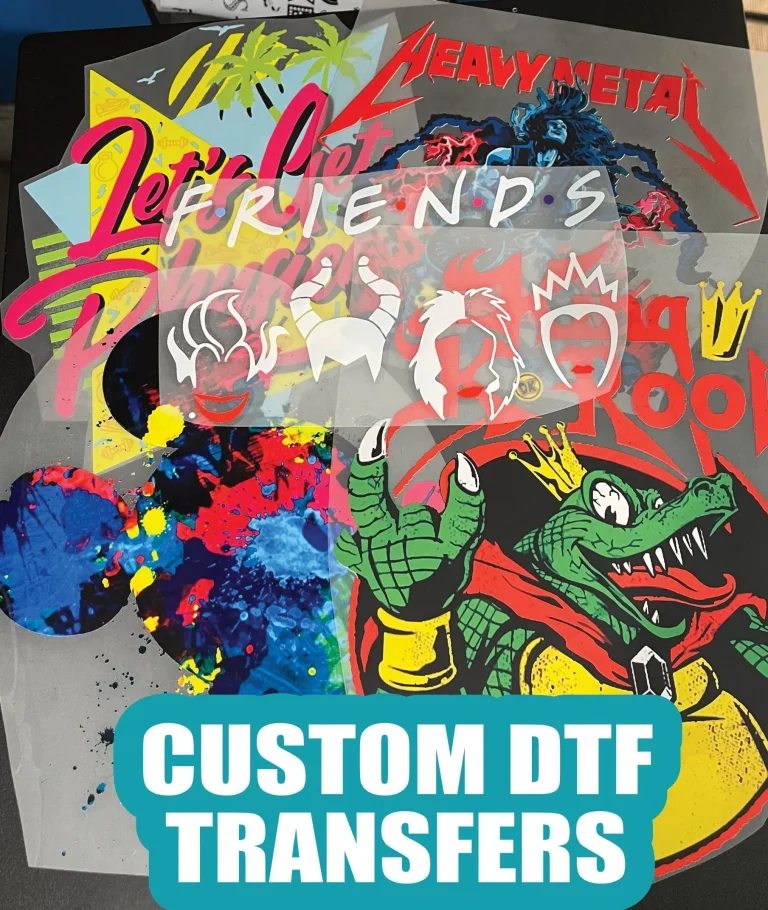

**DTF Transfers** are taking the printing industry by storm, particularly among small businesses seeking innovative solutions for custom apparel. Direct-to-Film printing provides a perfect blend of vibrant colors and high-quality designs, enabling businesses to create stunning prints on various fabrics. With the benefits of DTF transfers becoming increasingly apparent, many small enterprises are transitioning from traditional methods like screen printing to this more efficient, cost-effective alternative. As the demand for personalization grows, DTF’s ability to meet these needs positions it as one of the most preferred small business printing solutions. This introductory exploration highlights how DTF transfers can empower entrepreneurs to elevate their product offerings and appeal to a broader customer base.

Known also as Direct-to-Film or DTF print technology, this innovative custom printing method harnesses advanced printing techniques to produce high-quality transfers ideal for apparel and various fabric types. By applying ink onto a specific film that can be heat-pressed onto textiles, DTF offers flexibility that caters to the evolving demands of modern consumers. Small business owners are increasingly recognizing the advantages of these custom printing methods, especially when comparing DTF vs screen printing. This shift not only enhances the speed and efficiency of production but also opens up avenues for creativity in design and personalization. As we delve deeper into the benefits of DTF, it’s clear that this technology is a game-changer in the small business sector.

Understanding DTF Transfers and Their Mechanism

Direct-to-Film (DTF) Transfers is a cutting-edge printing technology that intricately blends the simplicity of direct-to-garment processes with the robustness of traditional screen printing. By printing designs onto a specialized film, businesses can create vibrant, high-quality images that can be transferred onto a variety of fabric types. This adaptability makes DTF printing particularly appealing for small businesses looking to diversify their product offerings while maintaining a commitment to quality.

The mechanism of DTF printing is relatively straightforward: after printing onto the film, a heat transfer process applies the design to the fabric surface using heat and pressure. This method not only ensures high fidelity in colors and details but also accommodates numerous fabric types, including cotton and polyester blends. As such, small enterprises can leverage DTF technology to cater to different market demands without needing expensive machinery or extensive training.

The Cost Benefits of DTF Transfers for Small Enterprises

One of the primary advantages of Direct-to-Film transfers is their cost-effectiveness compared to other printing methods such as screen printing or embroidery. DTF printing minimizes initial setup costs, enabling small businesses to start producing custom apparel without the hefty financial barrier often associated with traditional methods. This financial accessibility makes DTF transfers an attractive solution for entrepreneurs eager to enter the custom printing market.

Moreover, the low cost per print ensures that even small orders can be profitable. Since DTF transfers allow for printing on demand, businesses can avoid excess inventory, further cutting costs. The savings can then be funneled back into the business for marketing or enhancing product lines, establishing a sustainable growth model that is particularly crucial for small businesses.

Customization Options with DTF Transfers

In today’s consumer market, personalization is king. Direct-to-Film transfers empower small businesses to provide highly customizable options to their customers. Whether it’s unique designs for events, personalized gifts, or bespoke fashion items, DTF technology makes it feasible to cater to individual preferences efficiently. This personalization capability not only boosts customer satisfaction but also fosters loyalty—an essential aspect for small enterprises operating in competitive landscapes.

Additionally, the speed at which DTF transfers can produce customized items contributes to a responsive business model. This quick turnaround allows businesses to meet consumer demands for unique products, such as one-off designs that resonate with specific audiences. Thus, utilizing DTF technology ensures that small businesses remain relevant and appealing to modern consumers who crave individuality in their purchases.

Environmental Considerations in DTF Printing

As sustainability becomes increasingly important to consumers, Direct-to-Film printing positions itself as an eco-friendly option in the apparel printing industry. Many DTF inks are water-based, significantly reducing the ecological impact when compared to solvent-based inks commonly used in conventional screen printing. By adopting DTF transfers, small businesses can minimize their environmental footprint, which is an attractive factor for eco-conscious customers.

The ability to reduce waste is another environmental benefit associated with DTF transfers. The printing process allows for precision in design, which can substantially decrease the amount of material waste that occurs compared to other printing methods. This sustainable approach not only aligns with consumer values but can also enhance the brand image of small enterprises, making them more appealing to a demographic that values ethical considerations in their purchasing decisions.

DTF vs Screen Printing: Making the Right Choice for Your Business

When it comes to choosing a printing method, many small business owners often weigh the pros and cons of Direct-to-Film transfers versus screen printing. Screen printing, while renowned for its durability and vibrant colors, often requires larger quantities to be economical, resulting in high upfront costs and potential inventory issues. In contrast, DTF printing offers a more flexible, cost-effective solution that enables businesses to print smaller batches without sacrificing quality.

Furthermore, the learning curve associated with DTF technology is significantly less steep than that of screen printing. Small business owners without extensive printing experience can quickly familiarize themselves with the DTF process, minimizing operational downtime. For those seeking a balance between quality and practicality, DTF transfers present a modern alternative that aligns with the dynamic needs of today’s small enterprises.

Adopting DTF Transfers in Your Small Business Strategy

To remain competitive in a rapidly evolving market, it’s crucial for small businesses to integrate innovative technologies like Direct-to-Film transfers into their operational strategies. The versatility, affordability, and quality associated with DTF printing make it an excellent investment for those looking to expand their services. Business owners can utilize DTF technology not only to satisfy existing customer bases but also to attract new clientele looking for unique and affordable custom printing solutions.

Moreover, as technology continues to evolve, the capabilities of DTF printing are set to improve further. Business owners should stay informed about the latest advancements and consider how these innovations can enhance their product offerings. By embracing technologies like DTF transfers, small enterprises can not only keep pace with industry trends but also carve out a unique niche that appeals to modern consumers seeking personalized and efficient printing solutions.

Frequently Asked Questions

What are the key benefits of DTF Transfers for small businesses?

DTF Transfers, or Direct-to-Film printing, offer several key benefits for small businesses, including high-quality prints with vibrant colors, cost-effectiveness due to low overhead, simplicity in the printing process, and eco-friendliness with water-based inks. These advantages allow small enterprises to efficiently create customized products while appealing to a wider customer base.

How does DTF Transfers compare to traditional screen printing?

DTF Transfers differ from traditional screen printing in several ways. While screen printing often requires extensive setup and can be costly for small batch production, DTF offers a more cost-effective solution with quicker production times and the ability to print intricate designs on a variety of fabrics.

Are DTF Transfers a good solution for custom printing methods?

Yes, DTF Transfers are an excellent custom printing method for small businesses. They enable easy personalization and customization, allowing businesses to cater to individual customer preferences and niche markets effectively, all while maintaining high print quality and efficiency.

Can DTF Transfers be used on different fabric types?

Absolutely! One of the significant advantages of DTF Transfers is their versatility. This method allows for high-quality prints on various fabrics, including cotton, polyester, and blends, making it a perfect choice for diverse product offerings in the apparel industry.

What makes DTF Transfers a sustainable printing option?

DTF Transfers are considered a more sustainable printing option because many of the inks used are water-based, reducing environmental impact compared to traditional printing methods like screen printing, which often use solvents. This eco-friendly approach resonates with today’s consumers who favor sustainable practices.

How quickly can small businesses produce prints with DTF Transfers?

DTF Transfers excel in short production times, making them ideal for small businesses that need to meet tight deadlines or urgent customer requests. The efficiency of the DTF printing process allows for rapid turnaround on orders, helping businesses maintain strong customer relationships.

| Benefit | Description |

|---|---|

| Quality and Versatility | Delivers high-quality prints with vibrant colors on various materials, allowing for diverse product offerings. |

| Cost-Effectiveness | Eliminates high initial overhead, enabling small businesses to customize affordably, improving competitive edge. |

| Simplicity and Efficiency | Straightforward process with no steep learning curve, enhancing production efficiency and turnaround times. |

| Eco-Friendliness | Utilizes water-based inks, reducing ecological impact compared to traditional methods; appealing to eco-conscious consumers. |

| Short Production Times | Enables rapid printing to meet tight deadlines and urgent requests, improving customer satisfaction and operations scalability. |

| Customization and Personalization | Easily allows tailored products to enhance customer satisfaction and loyalty, catering to niche markets effectively. |

Summary

DTF Transfers are redefining the landscape for small businesses, especially in the printing and apparel industries. This innovative method offers unparalleled benefits, such as high-quality outputs, cost-effectiveness, and eco-friendliness, catering to the modern consumer’s demand for customization and rapid service. Embracing DTF Transfers not only positions small enterprises competitively but also enables them to adapt to the evolving landscape of consumer needs. As this technology continues to advance, small businesses adopting DTF will enhance their service offerings and operational efficiency, setting a new standard in the printing industry.