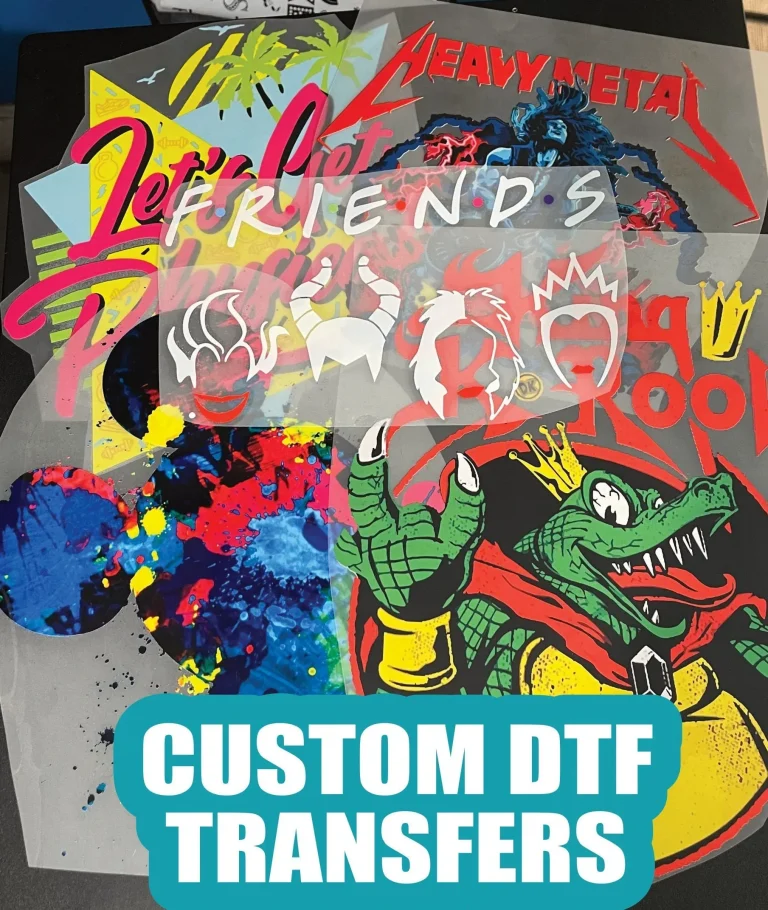

DTF transfers, or Direct-to-Film transfers, have become a game-changer in the world of textile printing, celebrated for their ability to produce stunning, high-quality designs on various fabric types. As more businesses dive into this exciting sector, mastering the best practices for DTF becomes crucial, especially when it comes to managing different DTF print sizes. This article delves into effective DTF transfer techniques, ensuring that your prints maintain their vibrancy and clarity, regardless of size. With a focus on DTF printing quality, we will explore the essential steps to achieve impeccable results, from artwork preparation to final application. Get ready to elevate your printing projects with insights that embrace both innovation and artistry!

The realm of textile printing has evolved significantly, with Direct-to-Film (DTF) applications and methods gaining traction among enthusiasts and industry professionals alike. Often regarded as an innovative printing solution, these film transfers enable vibrant and durable designs to thrive on a range of fabrics. As we explore the intricacies of DTF techniques, it is essential to consider the impact of print dimensions and artwork resolution on the final product. In this comprehensive guide, we will navigate the landscape of DTF printing, discussing optimal practices that ensure quality and satisfaction across different printing formats. Join us as we uncover the nuances that define successful transfers, from size selection to post-application care.

The Importance of Choosing the Right DTF Print Sizes

Choosing the correct size for your Direct-to-Film (DTF) transfers is essential for successful designs. The size of the print not only affects the aesthetic appeal but also influences how well the design translates to the final product. For smaller items like caps, a compact print can enhance visibility while ensuring intricate details are prominently displayed. In contrast, larger prints designed for t-shirts or hoodies must maintain vibrancy and coherence across bigger surfaces to avoid any visual disconnection that may arise from scaling.

Moreover, when determining DTF print sizes, consider the fabric type you will be using. Different fabrics may necessitate varying sizes of transfers due to their texture and physical dimensions. A design that works well on cotton may not convey the same impact on polyester or blends, making it imperative to customize accordingly. Overall, understanding the nuances of print sizes will greatly improve the quality and professionalism of your final apparel.

Enhancing DTF Printing Quality Through Artwork Resolution

The resolution of your artwork plays a critical role in the quality of DTF transfers. When producing transfers of varying sizes, it is vital to ensure that artwork is created at high resolutions—ideally 300 dpi. High-resolution images retain clarity, especially when scaled up for larger prints, providing sharpness and preventing pixelation. By utilizing vector graphics, designers can create intricate details that maintain their integrity regardless of size adjustments.

Additionally, paying close attention to the level of detail in your designs is crucial for larger prints. While finer aspects may appear beautiful at a smaller scale, they may lose definition when printed on a shirt. Simplifying complex designs without sacrificing their essence may result in better visibility and impact, which is essential for larger apparel pieces where graphics are intended to stand out.

Temperature and Pressure Settings for Optimal DTF Transfers

Correctly configuring temperature and pressure settings is fundamental to achieving durable, high-quality DTF transfers, particularly as the size of the print alters the dynamic of the application. Larger transfers generally require higher temperatures and more pressure to forge a strong bond between the film and the fabric. An incorrect setup can lead to common pitfalls such as peeling or fading—issues that can mar the integrity of larger designs.

On the other hand, smaller transfers require a more delicate touch, needing less pressure and shorter heating times. Over-application in these instances can damage the fabric or create unwanted distortions. Conducting preliminary tests with varying temperature and pressure settings aids in establishing the right balance, thus enhancing final product quality regardless of size.

Maintaining Color Consistency with DTF Inks

The choice of ink in the DTF printing process significantly influences the vibrancy and consistency of colors across different print sizes. With larger designs, maintaining color fidelity is essential; variations in ink application can lead to stark discrepancies that detract from the overall aesthetic. Using uniform ink types across all print sizes helps avoid color mismatches, ensuring that the branding remains consistent, which is a key aspect of professional presentation.

To guarantee accurate color matching, especially for larger applications, establishing a color profile is advisable. Engaging in extensive testing across various fabric types and under different lighting conditions ensures that colors remain consistent throughout the production process. Such attention to detail can enhance customer satisfaction and maintain brand reputation.

Conducting Tests on Various DTF Transfer Sizes

Conducting thorough tests on various sizes before launching a production run can save time and resources while optimizing the overall quality of DTF transfers. Assessing how different sizes affect the adherence and durability of designs allows printers to identify potential weaknesses before scaling up production. Larger transfers present unique challenges, such as the risk of cracking or improper bonding, necessitating specific techniques for successful application.

Sampling various dimensions on your chosen fabric enables an in-depth evaluation of results. Observing how each design behaves during pressing is crucial as it informs necessary adjustments that can lead to better overall product performance. Utilizing a structured testing approach ensures that all sizes meet the same high standards and quality metrics.

Implementing Effective Post-Transfer Techniques

Post-transfer techniques are pivotal in ensuring the longevity and overall quality of DTF prints, particularly for larger designs where the margin for error is reduced. After transferring the film, allowing it to cool completely before peeling is vital to prevent warping and ensure that the ink sets properly into the fabric. This careful approach can significantly extend the life of the design and its visual appeal.

In addition, handling the peeling process with care is essential. Management of large transfers requires gentle technique to avoid misalignment or damage to the design. The right post-processing methods not only enhance the aesthetic quality of the print but also solidify the bond with the fabric, leading to greater customer satisfaction and reduced returns.

Frequently Asked Questions

What are the best practices for DTF transfers to ensure high-quality results?

To achieve high-quality results with DTF transfers, it’s essential to use high-resolution artwork (at least 300 dpi), choose the appropriate film size for your design, and adjust temperature and pressure settings based on the transfer size. Testing and optimizing your techniques for different fabric types and sizes will also improve the final outcome.

How do DTF print sizes affect the final printed image?

DTF print sizes directly influence the final printed image’s appearance; smaller prints require precision and detail retention, while larger prints demand careful resolution management to avoid pixelation. Selecting the right size ensures vibrant colors and overall design integrity across various fabric types.

What DTF transfer techniques enhance the printing quality?

To enhance DTF printing quality, utilize vector graphics for scalable artwork, adjust heat press settings based on transfer size, and test different color profiles for consistency. Additionally, applying proper post-transfer techniques, such as cooling and gentle peeling, will prevent damage and maintain design quality.

Can I use the same ink type for different DTF transfer sizes?

Yes, using the same ink type across different DTF transfer sizes is crucial for achieving consistent color vibrancy and quality. This uniformity helps ensure that your branding remains intact and visually appealing, regardless of print size.

What should I consider when testing DTF transfers of various sizes?

When testing DTF transfers of various sizes, evaluate how the designs adhere during pressing and how well they hold up over time. Pay attention to any issues like cracking or uneven bonding, especially with larger prints, and make adjustments based on your observations.

How do fabric types impact DTF transfers?

Fabric types significantly impact DTF transfers; different materials react uniquely during the transfer process. For instance, stretchy fabrics may stretch during application, leading to defects in larger designs. It’s critical to research the fabric properties and adjust your techniques for optimal results.

| Key Point | Explanation |

|---|---|

| Understanding Film Dimensions | Select the appropriate film size, considering print size and detail. Larger prints may require adjustments in resolution. |

| Quality of Artwork and Resolution | Use high-resolution images (300 dpi) and vector graphics to maintain clarity during scaling. |

| Temperature and Pressure Settings | Adjust settings based on transfer size to ensure proper adhesion and avoid issues like peeling. |

| Ink Type and Color Matching | Use consistent inks across sizes to achieve uniform color, especially for larger designs. |

| Testing Different Sizes | Conduct tests on various sizes to ensure quality and appropriate application techniques. |

| Post-Transfer Techniques | Implement cooling and peeling practices to preserve design integrity, especially for larger prints. |

| Special Considerations for Fabric Types | Research fabric properties and adjust techniques to improve adhesion and durability. |

Summary

DTF transfers have become an essential technique in the textile printing industry, particularly because they allow for vibrant designs on various fabric types. When considering DTF transfers, it’s crucial to tailor practices according to the size of the transfer to achieve optimal results. From understanding film dimensions to adjusting temperature settings, each step is vital in ensuring high-quality prints. Testing different sizes and considering the type of fabric used are important to maintain the integrity and visual appeal of the designs. Following the best practices outlined above will not only improve the quality of your DTF transfers but also enhance the efficiency of your production process.