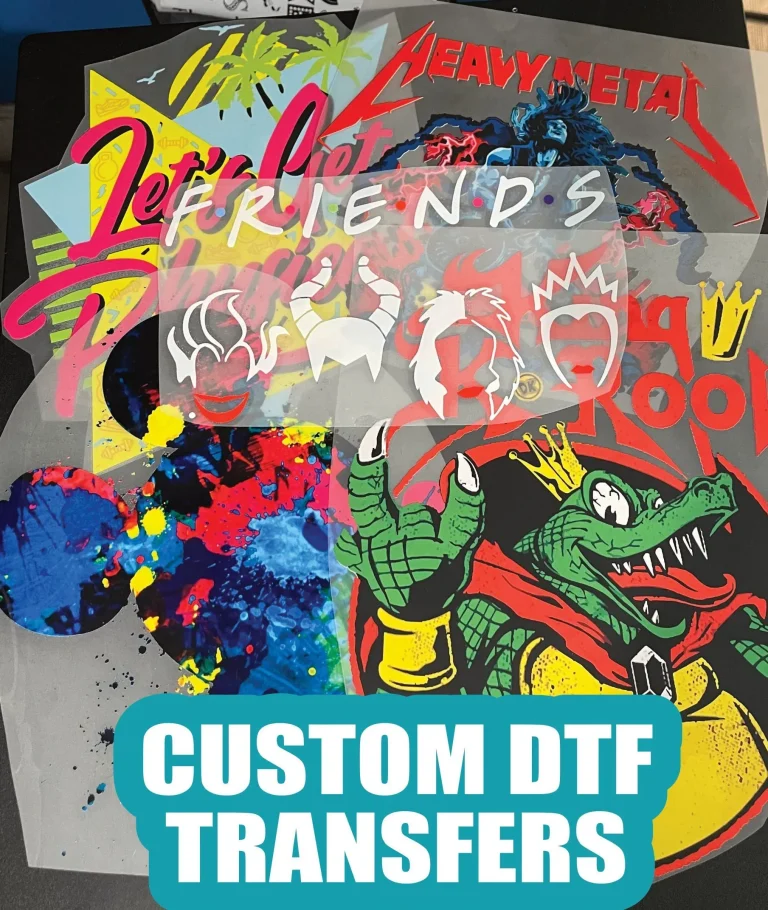

DTF transfers, or Direct-to-Film transfers, represent a groundbreaking advancement in garment printing, combining quality and versatility to create stunning apparel designs. Unlike traditional printing methods, DTF printing utilizes a unique film application that enables vibrant imagery and intricate detailing on various fabric types. This guide will delve into size considerations for DTF transfers, helping you optimize your projects by understanding the available transfer sizes and their applications in custom apparel printing. As the demand for personalized clothing continues to grow, mastering techniques such as DTF will empower you to elevate your design game. Let’s explore how to make the most of DTF transfer sizes to achieve outstanding results in your garment printing endeavors.

The innovative world of DTF transfer technology, also known as Direct-to-Film printing, has transformed the fabric printing landscape. This method empowers designers and businesses to produce custom clothing with exceptional detail and color vibrancy that was previously hard to achieve with conventional techniques. Understanding the implications of transfer dimensions not only enhances design effectiveness but also ensures that prints fit perfectly on diverse apparel items. As you explore various garment printing techniques, it’s essential to consider the optimal DTF transfer sizes to maximize visual impact. Join us on this journey to discover how to harness the full potential of DTF printing in your custom apparel projects.

Understanding DTF Printing Technology

DTF (Direct-To-Film) printing technology represents a significant breakthrough in the realm of garment decoration. By transferring designs directly onto a specially coated film, this method allows for the production of detailed and vibrant prints that were previously difficult to achieve with traditional techniques. The versatility of DTF printing means that it can be utilized across various fabric types, making it ideal for custom apparel printing ventures.

One of the key advantages of DTF printing lies in its ability to deliver high-quality results regardless of the fabric’s composition. Unlike other printing techniques, DTF does not suffer from limitations related to the type of material, as it works effectively on cotton, polyester, and even blends. This opens up opportunities for businesses in the custom apparel sector to cater to diverse customer needs, offering prints that stand out for their clarity and color vibrancy.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, utilize a specialized film to print vibrant designs that are then heat transferred onto garments. This innovative method enables intricate designs and a vast color palette, making it a popular choice for custom apparel printing.

What size considerations should I keep in mind for DTF transfers on different garments?

When using DTF transfers, size consideration is crucial. Standard transfer sizes vary; for example, T-shirts typically use 10 to 12 inches designs, while hoodies may require 12 to 14 inches. It’s important to select the right size to ensure the design fits well and maintains visual appeal.

How does film size affect the quality of DTF printing?

The standard film size for DTF transfers is often 13 inches by 19 inches. Choosing the appropriate film size is vital, as it must align with your printer’s capabilities to ensure high-quality output. Larger prints require higher resolution to avoid pixelation, thus impacting overall print quality.

What resolution should I consider for DTF transfer designs to ensure clarity?

For DTF transfers, maintaining a high resolution is essential, especially for larger designs. Aim for designs with at least 300 DPI, as higher resolution images ensure that details are crisp and prevent pixelation during the transfer process.

How can I test DTF transfer designs before final production?

To ensure quality and accuracy, conduct test prints of your DTF transfers before final production. By printing samples at various sizes, you can verify color fidelity and design integrity, ensuring the final product meets your expectations.

What are the benefits of DTF printing over traditional garment printing techniques?

DTF printing offers several advantages over traditional garment printing techniques, such as lower setup costs, flexibility in sizing options, and a broader color range. Additionally, newer eco-friendly inks in DTF processes cater to sustainability trends in the fashion industry.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A revolutionary printing method that transfers vibrant designs onto garments using a film and heat application. |

| Film Size | Commonly 13 inches by 19 inches, allowing a wide range of design sizes. Equipment must support this size for quality output. |

| Design Scaling | Maintaining aspect ratio is essential; use software like Adobe Illustrator to ensure clarity and prevent pixelation. |

| Choosing the Right Size | Transfer size depends on garment type; larger for hoodies, smaller for t-shirts and caps based on visible area. |

| Example Sizes | T-shirts: 10-12 inches, Hoodies: 12-14 inches, Caps: 3-5 inches. |

| Output Quality and Size | Higher resolution is key to avoid pixelation, especially for larger prints; ensure design details are maintained. |

| Quality Tips | Use high-quality images and perform test prints for color and design integrity verification. |

| Recent Developments | Advances in technology have improved DTF printing efficiency and quality, with eco-friendly inks being a growing trend. |

| Market Trends | Cost-effective and flexible sizing options make DTF appealing for small businesses; eco-friendly solutions are becoming popular. |

Summary

DTF transfers have revolutionized the printing industry by providing a method that combines flexibility and quality. By understanding DTF transfers and how size factors into the process, businesses can optimize their garment printing results. This guide emphasizes the importance of selecting the right film size, ensuring design integrity through scaling, and tailoring transfer sizes to various garments, leading to high-quality outputs. As technology continues to advance, those utilizing DTF transfers can enhance their apparel offerings, keeping pace with market trends that favor cost-effectiveness and sustainable practices.