In the realm of custom apparel printing, DTF transfers by size play a crucial role in the overall quality and appeal of your designs. This innovative fabric printing technique allows for vibrant, high-quality prints that can dramatically enhance the look of any garment. For beginners exploring DTF printing, understanding how to choose transfer sizes is an essential skill that can determine the success of your projects. From ensuring the design’s compatibility with various fabrics to meeting customer preferences, selecting the right size is key. Dive into this comprehensive guide to discover valuable DTF printing tips and essential considerations for maximizing the impact of your custom transfers.

Introducing the concept of DTF transfers involves understanding various expressions of this technique, commonly referred to as film-based transfer processes. This approach has gained popularity for its ability to deliver detailed, colorful designs onto textiles, making it a favorite among creative enthusiasts as well as small business owners. When discussing the selection of transfer sizes, it’s vital to grasp how this element influences not just visual aesthetics but also the practicality of the final application. Moreover, familiarizing oneself with fabric printing techniques can enhance one’s ability to tailor products effectively. By mastering the art of choosing transfer dimensions, one can refine their printing practice and cater better to diverse consumer needs.

The Basics of DTF Printing for Beginners

Direct-to-Film (DTF) printing is a revolutionary technique in the world of fabric printing, particularly for beginners looking to venture into custom apparel creation. This method involves transferring high-resolution images onto a film, which is then heat-pressed onto clothing items. Unlike traditional printing methods, DTF printing allows for vibrant and durable designs that stand out on various fabrics. For novices, understanding the basics is crucial not only to excel in this craft but also to make informed decisions about transfer sizes and suitable applications.

Beginners should familiarize themselves with the prerequisites of DTF printing, such as the types of inks used, the quality of transfer films, and the appropriate printing equipment. Acquiring a good DTF printer is essential since it determines the print quality and the maximum design dimensions possible. Additionally, knowing how to handle the heat press effectively is vital for applying the transfers correctly to achieve a professional finish.

Choosing DTF Transfers by Size: Key Considerations

When it comes to choosing DTF transfers by size, several factors play a crucial role in ensuring that the final product meets both aesthetic and functional standards. A significant consideration is the type of garment you are printing on. For instance, a larger design might overpower a fitted t-shirt, creating an unbalanced look, whereas a small design on a larger item may dilute the overall impact. Beginners should always evaluate the dimensions of their intended fabric before finalizing the size of their transfers.

Another important factor is the intended use of the item. Athletic wear, which typically requires smaller, more discreet designs due to added movement and flexibility, vastly differs from casual t-shirts that can accommodate larger, more striking graphics. Understanding these nuances will assist beginners in making selections that not only fit well but also resonate with potential customers.

Fabric Type and Transfer Size Compatibility

The fabric type plays a significant role in the choice of transfer sizes for DTF printing, impacting both the visual appeal and durability of the design. Stretchy fabrics, for instance, can distort larger prints, leading to a loss of detail and overall image quality. Conversely, on stiffer fabrics, bold designs can shine without any restrictions. Beginners must consider the elasticity and texture of the fabric when determining the appropriate size for DTF transfers.

Additionally, certain materials may respond better to specific types of inks, which can further influence the desirability of larger or smaller designs. By experimenting with various fabric styles and print sizes, beginners will gain crucial insights that help refine their approach to custom apparel creation and set them on a path to success.

Using Design Software to Optimize DTF Transfer Sizes

Harnessing the power of graphic design software is essential for beginners aiming to optimize their DTF transfer sizes effectively. Programs like Adobe Illustrator and free alternatives such as Inkscape and GIMP allow users to manipulate images, adjust dimensions, and visualize how different designs will look on various garments. By effectively utilizing these tools, beginners can ensure their prints are not only the right size but also maintain the integrity and quality associated with DTF printing.

Moreover, design software often includes features that can help simulate the appearance of prints on actual fabric, enabling users to make informed decisions before printing. Beginners should explore tutorials and resources available online to become proficient in using design software, ultimately leading to better print quality and customer satisfaction.

Current Trends in DTF Printing and Transfer Sizes

Staying updated with current trends in DTF printing can significantly enhance a beginner’s ability to choose the right transfer sizes. The shift towards personalization has led many customers to seek unique items, prompting businesses to adapt their offerings to include a variety of size options. Emphasizing current industry trends can provide insights into what customers prefer, influencing decisions about transfer sizes and design styles.

Additionally, newer DTF printers are continually coming into the market, often boasting enhanced functionalities and larger printing capabilities. Understanding these advancements allows beginners to push the boundaries of traditional designs, enabling them to experiment with sizing and create eye-catching custom apparel that aligns with market demands.

Practical Tips for Selecting Transfer Sizes

For beginners looking to choose the right transfer sizes in DTF printing, it’s crucial to follow some practical tips that can enhance decision-making and improve overall results. First, starting with test prints is essential; producing proof samples on different fabric types not only helps gauge the visual aspect of various sizes but also provides a better understanding of how materials react to transfers. This experimentation allows beginners to refine their process and avoid potential pitfalls.

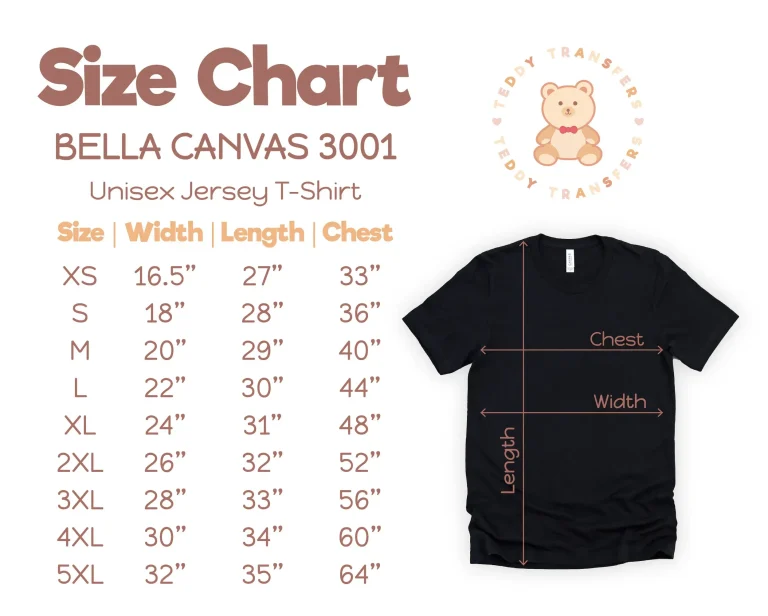

Furthermore, sticking to industry standard sizes can provide a baseline for decision-making. For instance, a width of 10-12 inches is often recommended for chest prints on t-shirts, whereas hoodies might accommodate sizes of 12-14 inches. Familiarizing oneself with these common sizes will streamline the design process and ensure that beginners create high-quality, market-ready products efficiently.

Frequently Asked Questions

What is the best way to choose DTF transfers by size for t-shirts?

When selecting DTF transfers for t-shirts, it’s recommended to choose a width of 10-12 inches for chest prints. This size generally ensures the design is prominent but not overpowering, maintaining a balance between visual appeal and garment style.

How do fabric types affect DTF transfer sizes?

Different fabric types can impact the effectiveness of DTF transfer sizes. For instance, larger designs on stretchy fabrics may distort, affecting clarity. It’s essential to choose sizes that complement the fabric’s elasticity and intended use, ensuring that designs maintain quality.

What are some common size guidelines for DTF transfers on hoodies?

For hoodies, a size range of 12-14 inches for designs is typically recommended. This larger size accommodates the dimensions of hoodies while ensuring that designs are visually striking and fit well within the garment’s layout.

How can I test DTF transfer sizes before printing large batches?

Before committing to large print runs with DTF transfers, conduct test prints on various fabric types. This practice not only helps you evaluate the ideal sizes but also familiarizes you with material behavior, ultimately preventing waste and enhancing quality.

What role do customer preferences play in choosing DTF transfer sizes?

Customer preferences are essential when choosing DTF transfer sizes. Engaging with your audience can provide insights into whether they prefer bold, large designs or smaller, minimalist prints, allowing you to tailor your offerings to meet market demands effectively.

Are there software tools that help with choosing DTF transfer sizes?

Yes, graphic design software such as Adobe Illustrator or free alternatives like GIMP can assist in adjusting and manipulating DTF transfer sizes. These tools allow you to visualize how designs fit within various garment dimensions, ensuring an optimal final product.

| Aspect | Details |

|---|---|

| Understanding DTF Transfers | DTF printing involves applying vibrant designs to textiles using a special film and heat press. |

| Importance of Size | Critical for design compatibility, fabric reactions, printing equipment limitations, and customer preferences. |

| Design Compatibility | Transfer size must suit the garment; too large or too small can affect appeal. |

| Fabric Type | Different fabrics may distort larger designs; consider casual vs. fitted apparel. |

| Equipment Limitations | Know the maximum print area of your DTF printer to avoid oversized designs. |

| Customer Preferences | Engaging customers can help determine the best size for your designs. |

| Recommendations for Beginners | Test different sizes, follow recommended sizes for garments, use design software. |

| Common Sizes | T-shirts: 10-12 inches, Hoodies: 12-14 inches, Caps: 2.5-3 inches. |

| Current Trends | Evolving equipment, increased customization, and online resources for learning. |

Summary

DTF transfers by size is a crucial aspect to consider for anyone venturing into fabric printing. The choice of transfer size directly affects design compatibility, fabric interaction, and customer satisfaction. By understanding the vital relationship between transfer sizes and the garments they adorn, you can elevate your printing projects to new heights. Remember to conduct test prints, adhere to common sizing guidelines, and tap into the vast online resources available. With this informed approach, you’ll be well-equipped to succeed in the dynamic world of DTF printing.