DTF transfers by size are a pivotal aspect of the Direct to Film (DTF) printing process, significantly influencing the quality and clarity of your textile prints. As the demand for personalizable and vibrant designs increases, understanding DTF transfer sizes helps both novices and seasoned professionals optimize their printing projects. This comprehensive DTF printing guide will walk you through essential information regarding transfer sizes, offering beginner tips for DTF and advanced techniques for professional DTF printing. From selecting the right transfer dimensions to enhancing your textile printing techniques, mastering DTF transfers is crucial in achieving stunning and durable results. Join us as we explore everything you need to know to elevate your DTF printing skills!

Understanding the dimensions of DTF transfers is essential for anyone eager to dive into the realm of textile printing. By exploring different DTF transfer sizes, you can tailor your designs to suit various fabric types and project requirements. This discussion not only caters to beginners looking for foundational knowledge but also provides intricate details for professionals aiming to refine their techniques. With a focus on transfer dimensions, this guide serves as an invaluable resource for enhancing your printing capabilities, ensuring that both simple and complex designs come out looking exceptional. Whether you refer to them as DTF print sizes or transfer dimensions, grasping these concepts is key to mastering the art of DTF printing.

Understanding DTF Printing Techniques

Direct to Film (DTF) printing has emerged as one of the most innovative and efficient textile printing techniques in recent years. This method allows printers to create vibrant, eye-catching designs that can be seamlessly transferred onto various fabric types. Unlike traditional screen printing, which may require multiple screens and complex setups, DTF simplifies the process, cutting down on both time and materials needed for production. As you familiarize yourself with the DTF printing process, it’s essential to grasp the different techniques involved for achieving the best outcomes.

The fundamental element of DTF printing is the direct transfer from film to fabric. This method utilizes specialized inks that bond with the polyester film, capturing intricate details and colors with remarkable precision. Key considerations include selecting the appropriate ink types and transfer films that suit your specific fabric choices. By mastering these techniques, printers can ensure high-quality results while still maintaining the flexibility to adapt to various project requirements.

DTF Transfers by Size: Choosing the Right Dimensions

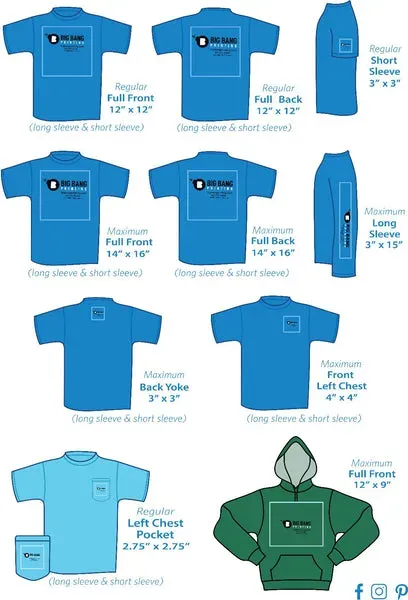

When diving into DTF printing, understanding the importance of transfer sizes cannot be overstated. DTF transfers by size play a crucial role in determining the effectiveness of the final product. For beginners, sticking to standard sizes like 11″ x 14″ is recommended as they accommodate most small to medium design concepts with ease. It is important for new users to take note of these sizes, as the wrong dimensions can lead to subpar prints, affecting both quality and customer satisfaction.

For professionals, however, the world of custom sizes opens up new horizons for creativity. Adjusting transfer sizes based on individual garment dimensions can enhance the fit and aesthetic appeal significantly. For example, creating oversized prints for hoodies or custom shapes for unique apparel can set your work apart in a competitive market. Thus, adapting your techniques to include both standard and custom transfer sizes is advantageous for maximizing print quality and customer appeal.

Essential Tips for DTF Beginners

Starting your journey in DTF printing can be intimidating, but following some beginner tips can set you on the right track. First, it’s vital to familiarize yourself with the equipment and settings. Using standard sizes for initial projects will help you comfortably navigate both the printing process and the application of heat, minimizing error margins as you learn. Begin with small designs to practice heat application and print management, which will build your confidence as you progress.

Another crucial tip is to maintain a strong focus on quality control. Ensure that the images you use for your transfers are high resolution; this detail significantly impacts the print’s clarity and vibrancy. The beauty of DTF printing lies in its ability to reproduce bright, lifelike designs, which will enhance the appeal of your finished products. Always remember, detail matters in DTF — making sure to get it right from the start will save you a lot of time and resources later.

Pro Tips for Advanced DTF Printing

As you transition into advanced DTF printing techniques, there are several pro tips that can elevate your work. Custom sizing is one of the most beneficial strategies for experienced users; by adjusting your DPI settings, you can increase the resolution and complexity of your designs. This capability allows you to produce intricate, high-quality prints that stand out, particularly important in the competitive field of fashion and custom apparel.

Moreover, exploring a variety of materials and transfer films can significantly enhance your results. Different fabric types respond uniquely to various inks and films; therefore, understanding the compatibility of your supplies is key to achieving optimal results. Experimentation becomes crucial in this phase—as you learn how different factors impact the durability and appearance of your prints, you can refine your process to better meet varied customer demands.

Innovations in DTF Printing: Upcoming Trends

The world of DTF printing is consistently evolving, with exciting trends emerging that enhance both the quality and environmental friendliness of transfers. One significant development is the rise of biodegradable films and eco-friendly inks. These innovations make it possible for printers to create products that appeal to sustainability-conscious consumers while maintaining high printing standards. Staying updated on these trends will not only benefit your business’s ecological footprint but can also attract a new clientele.

Moreover, advancements in printing technology further streamline the process, allowing for better precision and faster production speeds. New printing machines and software tools enable designers to tackle larger, complex projects with ease. As you improve your skills and adapt to these innovations, you can capitalize on the increasing demand for high-quality, customized textile products in a competitive market.

Resources for Mastering DTF Printing

For enthusiasts looking to deepen their expertise in DTF printing, utilizing online resources can provide invaluable knowledge and practical tips. Websites such as Printful offer comprehensive guides that cover DTF printing essentials, making them suitable for both beginners and seasoned professionals looking to refine their skills. These resources are perfect for gaining insights into best practices that can enhance your printing techniques.

Additionally, platforms like ColDesi specialize in equipment and advanced printing techniques, offering in-depth discussions tailored for those engaging in professional-level DTF printing. Engaging with such resource-rich sites allows users to expand their understanding of the technology, discover new tools, and stay informed about current trends in the industry, which can ultimately improve the quality of their output.

Frequently Asked Questions

What are the standard DTF transfer sizes recommended for beginners?

For beginners, it’s advisable to start with the standard DTF transfer size of **11″ x 14″**. This size is manageable and suitable for most design concepts, making it easier to learn the printing and heat application processes without overwhelming complexity.

How can I determine the right DTF transfer size for my garment?

To determine the right DTF transfer size for your garment, consider the garment dimensions and the design’s complexity. Standard sizes like **11″ x 14″** work well for shirts, while custom sizes might be necessary for larger items like hoodies or banners to ensure a perfect fit.

What DPI settings should I use when creating custom DTF transfers?

When creating custom DTF transfers, using a DPI setting of at least **300** is recommended for high-resolution images. This ensures that your designs remain vibrant and detailed, especially when adjusted to fit larger transfer sizes.

What are some essential tips for applying DTF transfers of different sizes?

Regardless of transfer size, it’s crucial to maintain appropriate temperature and pressure settings during application. A common recommendation is to heat press at **320°F for 15 seconds**, but adjustments may be needed based on the fabric type and transfer size.

How can professionals optimize their workflow for DTF transfers by size?

Professionals can optimize their workflow by calculating the most efficient DTF transfer sizes based on order volume. This minimizes waste and saves time, allowing for streamlined production processes, especially when working with larger transfer sizes.

Are there any upcoming trends related to DTF transfer sizes in the printing industry?

Yes, upcoming trends in DTF printing include the development of larger transfer sizes and eco-friendly options, such as biodegradable films and sustainable inks. These advancements cater to market demands while enhancing the versatility and efficiency of DTF transfers.

| Aspect | Description |

|---|---|

| DTF Transfers | A method of directly printing images onto a special film for transfer onto fabrics. |

| Standard Sizes | Commonly used size of 11″ x 14″ for shirts; easier for beginners. |

| Custom Sizing | Allows for unique dimensions and improved resolution, especially for experienced users. |

| Tips for Beginners | Start small, ensure quality control, and manage heat settings for best results. |

| Tips for Professionals | Experiment with sizes, materials, and optimize production efficiency. |

| Upcoming Trends | Innovations include biodegradable films and technology for larger transfers. |

Summary

DTF transfers by size are pivotal for optimizing your textile printing outcomes. Understanding the impact of transfer dimensions is essential, whether you are a beginner or an experienced professional. By choosing the right size for your projects, you can enhance the creativity of your designs and ensure high-quality prints. As DTF printing gains momentum, embracing these insights will empower you to take full advantage of this innovative technology, allowing for more stunning and effective textile applications.