DTF transfers by size play a pivotal role in achieving stunning and effective designs in the realm of custom printing and apparel design. As you embark on the journey of utilizing DTF (Direct-to-Film) transfers, understanding the significance of transfer sizes becomes vital. This knowledge ensures that your designs not only appear visually striking but also fit harmoniously on the chosen garments, whether it’s t-shirts, hoodies, or tote bags. With a focus on DTF transfer sizes, this article delves into the nuances essential for maximizing the aesthetic quality and application of your custom DTF transfers. By mastering the art of sizing and placement, you can elevate your apparel designs to new heights, ensuring they resonate with your audience.

When it comes to custom printing, grasping the concept of DTF transfer sizes is crucial for designers and businesses alike. DTF printing, or Direct-to-Film printing, offers a vibrant canvas to showcase intricate designs on a variety of apparel and merchandise. Understanding the intricacies of transfer sizes not only enhances the visual appeal but also optimizes the overall effectiveness of the printed graphics. In this exploration, we will cover essential DTF design tips that emphasize the importance of matching the correct transfer dimensions to your chosen garment, ensuring that your personalized creations maintain their intended impact and quality.

The Advantages of DTF Transfers in Custom Printing

DTF transfers have revolutionized the custom printing industry with their ability to produce vibrant and detailed designs suitable for a variety of applications. Unlike traditional screen printing or heat transfer methods, DTF printing allows for an impressive color range and complexity, making it the preferred choice for designers who wish to create unique apparel pieces. The flexibility of DTF transfer sizes accommodates diverse garment types, allowing businesses to expand their offerings without compromising on design quality.

Beyond their versatility, DTF transfers stand out due to their durability and resilience. High-quality DTF materials adhere exceptionally well to various fabrics, which enhances the longevity of the designs. As more customers seek personalized items, DTF transfers provide a solution that meets both aesthetic and functional needs, positioning themselves as an essential tool for custom printing services.

Choosing the Right DTF Transfer Size for Your Garments

When selecting DTF transfers, size is a critical factor that can significantly impact the final product. The ideal DTF transfer size depends on multiple factors such as the garment type, design complexity, and placement on the fabric. For instance, large and intricate designs can benefit from larger transfer sizes, ensuring the details are visible and impactful. On the other hand, smaller garments like onesies may require more compact transfers to avoid overwhelming the design.

Understanding DTF transfer sizes also means appreciating the blank canvas your garment provides. Different clothing items have varying areas available for design application. For example, a graphic t-shirt may effectively showcase a large transfer, while the same size might be overwhelming on a smaller accessory like hats or socks. Careful consideration of the dimensions helps in making informed decisions that enhance the total appeal of the product.

Market Trends Driving DTF Transfer Customization

As the demand for personalized apparel continues to rise, so does the popularity of DTF transfers. More and more brands are seeking to differentiate themselves by offering customized products that reflect their clients’ individuality. This shift has paved the way for trends emphasizing the importance of bespoke DTF transfer sizes that cater to a variety of designs and preferences, underscoring the industry’s adaptability.

Recent market analyses suggest that businesses embracing DTF technology are reaping the rewards. Companies that invest in custom DTF transfers not only elevate their product offerings but also enhance customer satisfaction, leading to stronger brand loyalty. This trend indicates that suppliers must keep pace by offering a wider range of transfer sizes to meet the evolving needs of designers and consumers alike.

Maximizing Quality in DTF Transfers

Achieving the best results with DTF transfers is not solely about size; it is also about quality. Utilizing high-grade materials ensures that the printed designs are both vibrant and resistant to wear and tear. DTF transfer quality can be enhanced by selecting compatible inks and films that are specifically engineered for this printing method. By opting for superior quality, designers can elevate their projects, ensuring lasting impressions on their audience.

Additionally, it’s vital to conduct trials with different transfer sizes to identify which best fits the intended garment and design. Print testing allows designers to visualize how various sizes interact with the fabric, influencing both aesthetics and durability. Adhering to recommended guidelines from DTF manufacturers is another way to optimize printing efforts, leading to refined outcomes.

Essential Tools for DTF Transfer Sizing

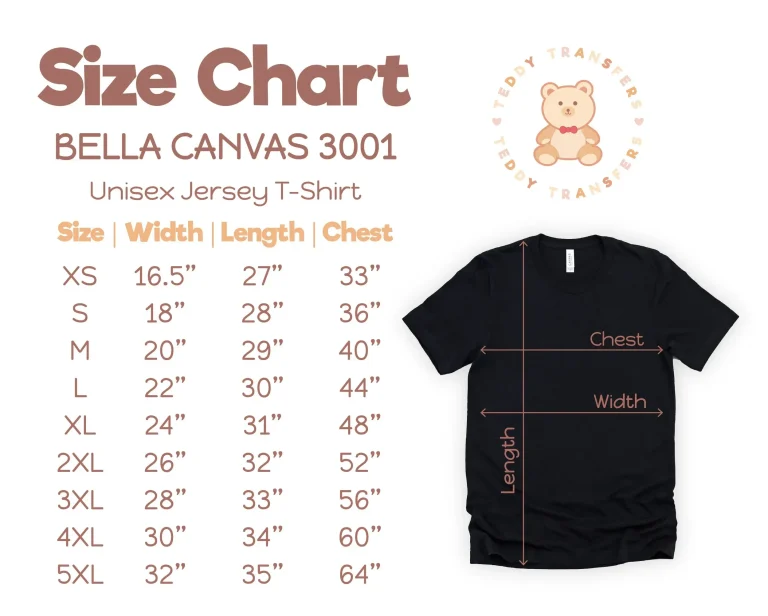

Navigating the complexities of DTF transfer sizes is made significantly easier with the right tools at your disposal. Various online resources and design software are available to assist designers in selecting the optimal transfer size for their projects. These tools often include size charts and templates that allow creatives to visualize how designs will look on garments before committing to an order.

Moreover, engaging with online communities and professional forums can provide additional insights and recommendations on best practices concerning DTF sizing and design. Tutorials, case studies, and user experiences share valuable information about utilizing tools effectively, enhancing overall efficiency in the design process.

Tips for Effective DTF Design Application

Implementing effective DTF design techniques directly contributes to the overall notion of creating successful products. Understanding design dimensions and garment placement is paramount to ensure that the transfer not only fits well but also enhances the visual appeal of the final item. By carefully planning out the application strategy, designers can prevent common issues like misalignment or excessive resizing.

In addition to planning, seeking continuous improvement through feedback and testing is crucial for mastering DTF applications. Iterating on designs based on previous outcomes can lead to refined approaches and ultimately elevate the quality of future DTF projects. This commitment to excellence ensures that designers remain competitive in a rapidly evolving market.

Frequently Asked Questions

What factors should I consider when choosing DTF transfer sizes for my designs?

When selecting DTF transfer sizes, consider the type of garment you’re using, the dimensions and intricacy of your design, and the desired placement on the garment. Each of these factors plays a crucial role in ensuring your custom DTF transfers look great and maintain design integrity.

How does garment type influence DTF transfer sizes?

The type of garment significantly influences DTF transfer sizes. For example, larger designs may work well on t-shirts or hoodies, while smaller designs are more suitable for baby onesies or accessories. Ensuring the right fit enhances the overall appeal of your custom DTF creations.

Can I customize DTF transfer sizes for different projects?

Yes! One of the advantages of DTF printing is the ability to customize transfer sizes to meet the specific needs of your project. This flexibility allows you to accommodate various design dimensions and garment types effectively.

What are the best design tips for ensuring quality DTF transfers?

To achieve high-quality DTF transfers, focus on using quality materials, testing various sizes for your designs, and following printer guidelines for optimal sizing. These practices help preserve the vibrancy and durability of your DTF designs.

How can I find the right size for my DTF transfers?

Many DTF printing companies provide size charts and customization tools online to help you determine the best sizes for your transfers. Additionally, utilizing design software and instructional resources can guide you in visualizing your designs on different substrates.

What is the significance of correct DTF transfer sizes in apparel design?

Choosing the correct DTF transfer sizes is crucial for ensuring that your designs not only look aesthetically pleasing but also fit well on the garments. Proper sizing enhances the visual impact and functionality of your custom DTF designs, ultimately contributing to customer satisfaction.

| Key Points | Details |

|---|---|

| Definition of DTF Transfers | DTF (Direct-to-Film) transfers allow for detailed designs printed on film and transferred onto various fabrics. |

| Importance of Size | Choosing the right transfer size ensures designs fit well and maintain visual integrity on garments. |

| Factors Influencing Size Choice | Garment type, design dimensions, and placement all influence the optimal size for DTF transfers. |

| Market Trends | Growing demand for personalized apparel increases the need for customizable DTF transfer sizes. |

| Techniques for Quality Transfer | Using quality materials and testing sizes before finalizing designs can enhance DTF transfer quality. |

| Resources for DTF Sizing | Various online tools and size charts help determine the best sizes for DTF transfers. |

Summary

DTF transfers by size play a crucial role in achieving visually compelling and functional designs in the custom printing landscape. Understanding the various sizes available enables designers to tailor transfers that not only merge seamlessly with chosen garments but also amplify the overall aesthetic appeal. As the custom apparel market continues to evolve, staying informed about DTF transfer sizing and utilizing available resources becomes essential for any designer aiming to thrive in this dynamic industry. By making informed choices regarding transfer sizes, creators can ensure their designs stand out, resonate with their audience, and fulfill the growing demand for personalized apparel.