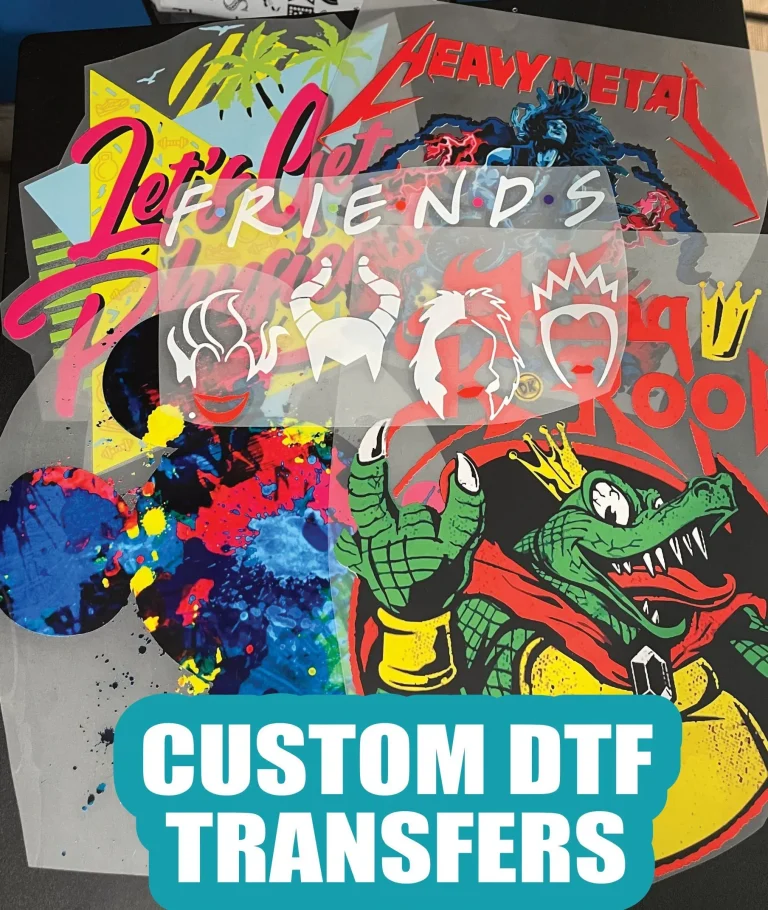

DTF Transfers have revolutionized the world of custom apparel printing, offering a seamless way to transfer high-quality designs onto various fabric types. This innovative technique, known as Direct-to-Film (DTF) printing, allows for intricate artwork to be printed onto a special film and easily heat-transferred to garments. Entrepreneurs and hobbyists alike are drawn to its versatility and the potential to produce stunning prints that stand out. However, understanding transfer size guidelines is crucial for maximizing print quality and ensuring that designs translate perfectly onto fabrics. In this guide, we will explore essential tips and techniques for achieving print perfection with DTF transfers.

Referring to Direct-to-Film prints, or DTF techniques, offers a dynamic approach to custom garment decoration. By utilizing innovative printing methods, designers can create personalized apparel, from t-shirts to hoodies, with striking visuals that capture attention. In the realm of this imprinting technique, determining the correct transfer dimensions is vital; it influences not only the aesthetic of the piece but also its overall quality. This article delves into effective strategies for optimizing transfer sizes and enhancing print fidelity, providing crucial insights for those engaged in the artistic fabric printing industry.

The Basics of DTF Printing Technology

Direct-to-Film (DTF) printing technology has revolutionized the custom apparel industry, allowing for high-resolution designs to be printed on a film and subsequently transferred onto various fabric types. The process involves printing the desired artwork on a specialized film that has been coated to accept the ink, providing a solid foundation for vibrant colors and intricate details in the final product. As a result, DTF transfers have become a go-to solution for both small businesses and hobbyists who seek to bring their unique designs to life.

The versatility of DTF printing transcends the limitations of traditional screen printing, as it enables printing on a range of materials including cotton, polyester, and blends. This flexibility is especially advantageous for custom apparel, where the ability to adapt designs to different fabric types opens up a multitude of creative possibilities. Understanding the core mechanics of DTF technology is crucial for maximizing print quality and ensuring successful transfers.

Optimizing DTF Transfer Sizes for Better Results

When it comes to DTF transfers, the size of your graphic significantly impacts print quality. Larger transfers not only enhance visual appeal but also showcase intricate design elements that smaller prints might obscure. However, choosing the right transfer size requires a keen consideration of the garment type, as well as the intended use of the finished product. Standardizing sizes—such as small, medium, and large—can streamline production and ensure consistency across different printing runs.

Moreover, adhering to optimal transfer size guidelines bolsters the likelihood of achieving a professional finish. A transfer that is too large may overwhelm certain fabric types and distort design features, while a transfer that is too small might fail to convey the intended artistic message. Thus, aligning transfer dimensions with garment specifications is vital for maintaining design integrity and enhancing overall product quality.

For best results, it’s also essential to factor in print width versus actual transfer size. While your printer may accommodate larger film widths, adjusting the design scale for the specific garment type enhances the overall cohesion of the printed image. This forms an integral part of the pre-press preparation process that ultimately influences print success.

Essential Print Quality Tips for DTF Transfers

Achieving optimum print quality with DTF transfers hinges on several key practices that can greatly enhance the final outcome. One of the most crucial steps involves ensuring that your artwork is set at a minimum resolution of 300 DPI. High-resolution designs guard against pixelation and achieve crisp, vibrant outputs that attract customers. Additionally, maintaining this standard opens pathways for expanding your offerings, allowing you to cater to more intricate designs without compromising on quality.

Another important print quality tip is to conduct thorough tests on scrap fabric before moving to final production. Test printing not only allows for adjustments in design size and placement but also provides an opportunity to verify color accuracy, ensuring that what appears on screen translates well onto fabric. By investing time in testing, you can mitigate the risk of costly production errors and refine your techniques to achieve more consistent results.

Pre-Press Techniques to Enhance DTF Transfer Success

Preparation is key to a successful DTF transfer, and the pre-press stage holds significant influence over the final product quality. One effective method is to apply a pre-treatment solution to garments prior to printing, which enhances ink adhesion and promotes a vibrant finish. This preparatory step can be a game changer in achieving adherence that guarantees longevity, even after multiple washes.

Furthermore, closely examining the fabric type prior to printing is crucial. Different materials respond uniquely to DTF transfers, and understanding these variances ensures that your prints will appear as intended. By experimenting with various fabric types during the pre-press process, printers can adapt their techniques to yield the best results, ultimately expanding their repertoire of printing capabilities.

Innovative DTF Printing Techniques for Modern Applications

The DTF printing landscape is continuously evolving, with innovative techniques being adopted to enhance production efficiency and print quality. One notable advancement is the adoption of eco-friendly and high-quality inks, which create long-lasting, vibrant images while being more environmentally responsible. These advancements cater to a market increasingly focused on sustainability, allowing custom apparel businesses to align themselves with ethical practices.

Additionally, experiments with curing techniques and temperature control have emerged as essential parts of the DTF printing process. Findings reveal that the combination of proper curing temperature and duration significantly affects the adhesion and longevity of the print. Keeping abreast of these modern techniques not only helps producers enhance their product offerings but also provides opportunities for differentiation in a competitive market.

Emerging Trends in Custom Apparel Printing

The custom apparel printing marketplace is rapidly evolving, with DTF printing at the forefront of this transformation. Small business owners and entrepreneurs have recognized the increasing demand for personalized apparel, driving innovation in printing technology and practice. By leveraging DTF, they can produce high-quality, custom pieces that cater to niche markets, paving the way for a new wave of creativity in fashion.

Moreover, as consumer preferences shift toward unique, personalized clothing, printers are embracing flexible print models that adapt to evolving trends. Incorporating seasonal designs, limited editions, and on-demand printing are some strategies that businesses are employing to meet customer expectations. Staying attuned to these trends and adopting innovative practices can profoundly influence the viability and success of custom apparel ventures.

Frequently Asked Questions

What is the process of DTF transfers in custom apparel printing?

DTF transfers involve printing designs onto a specially coated film, which are then transferred to fabric using heat and pressure. This method allows for detailed and vibrant designs, making DTF printing a popular choice in custom apparel printing.

How does transfer size impact the print quality of DTF transfers?

Transfer size is crucial; larger DTF transfers can enhance detail and visibility. However, larger sizes require high-resolution files to maintain sharpness and prevent pixelation, ensuring high-quality prints.

What are optimal size guidelines for DTF transfers on apparel?

Most DTF printers can handle widths up to 13 inches, suitable for t-shirts and hoodies. It’s advisable to maintain standard sizes like small, medium, and large for consistency across garment types.

What design considerations should I keep in mind for DTF printing?

Ensure your artwork fits the garment and maintain a minimum resolution of 300 DPI for intricate designs. This helps achieve sharp and clear prints, crucial for quality DTF transfers.

What are some print quality tips for successful DTF transfers?

Pre-treat fabrics before printing to enhance ink adhesion, conduct test prints on scrap material for adjustments, and experiment with various fabric types to optimize DTF print quality.

How do emerging technologies impact DTF printing techniques?

Advancements in adhesive technology and eco-friendly inks are enhancing the quality and durability of DTF transfers, allowing manufacturers to cater to environmentally conscious consumers and improve print longevity.

| Key Point | Details |

|---|---|

| Understanding DTF Transfers | DTF printing involves printing designs onto a coated film, then transferring onto fabric using heat and pressure. |

| Size Matters | Larger transfers can provide richer detail but require higher resolution files to avoid pixelation. |

| Optimal Size Guidelines | Most DTF printers can handle film widths up to 13 inches, suitable for t-shirts and hoodies. |

| Design Considerations | Artwork should maintain a minimum of 300 DPI to ensure clarity and sharpness in prints. |

| Print Width vs. Transfer Size | Adapt design size to garment type to avoid overwhelming the fabric. |

| Pre-Press Preparation | Pre-treating garments enhances adhesion and print quality. |

| Test Samples | Conducting test prints allows for adjustments to size, positioning, and color before final production. |

| Experimentation with Fabric Types | Different fabrics require unique printing techniques for optimal results. |

| Emerging Technologies | Advancements in adhesives and eco-friendly inks are enhancing print longevity and market appeal. |

| Market Trends | The rise in demand for custom apparel is driving growth and efficiency in DTF printing technology. |

Summary

DTF Transfers are revolutionizing the custom apparel printing sector by allowing for high-quality, detailed designs to be printed on various fabrics. Understanding their significance in sizing is crucial for achieving print perfection. By implementing optimal size guidelines and pre-press techniques, individuals and businesses alike can improve their results in custom printing. As the DTF market evolves, staying abreast of emerging technologies and trends will enable entrepreneurs to produce top-notch products that meet consumer demands.