DTF Transfers by Size are becoming a pivotal element in the realm of custom apparel printing, where precision and visual appeal hold significant importance. Direct-to-Film (DTF) transfers have transformed how high-resolution images are applied to fabric, allowing for vibrant designs that capture attention. However, understanding the nuances of transfer sizes is crucial for any effective printing project, as discrepancies can lead to compromised image quality. This guide delves into the essential guidelines for utilizing DTF transfers by size, ensuring that your custom designs look stunning on any garment. Embark on this journey of mastery in DTF printing, where we empower you with insights that can elevate your apparel printing game.

In the sphere of custom garment creation, the sizing of Direct-to-Film transfers plays a crucial role in delivering superior print quality and aesthetic appeal. Often referred to as DTF printing, this advanced technique involves applying high-resolution graphic designs to various textiles through a unique transfer process. Understanding the dynamics of transfer dimensions is essential for achieving optimal results, as smaller or larger sizes can significantly influence the overall presentation of the design. This discussion will explore how the placement and proportions of transfer sizes impact not only the design’s clarity but also its durability and effectiveness on different fabric types. Join us as we navigate through essential DTF transfer guidelines, helping you to make informed decisions in your custom apparel printing endeavors.

Maximizing Quality with DTF Printing Techniques

DTF printing is at the forefront of custom apparel creation, giving businesses a distinct edge in a competitive landscape. To achieve exceptional results, understanding and applying the correct techniques is paramount. High-resolution printing is essential, especially when working with intricate designs. The process allows for vivid colors and detailed graphics, transforming basic clothing into eye-catching apparel that resonates with customers. By utilizing top-quality printers and inks, businesses can ensure that each transfer maintains its vibrancy and sharpness, providing long-lasting satisfaction for clients.

Moreover, mastering the techniques specific to DTF printing can elevate the quality of the final product. Factors such as pressure settings and temperature calibration heavily influence the outcome of the print. Ensuring that these variables align with the nature of the fabric being printed on can prevent issues related to blurriness or fading. Experimenting with different fabric types and transfer techniques can unveil optimal combinations that not only look good but also endure wear and maintaining their appearance over time.

DTF Transfers by Size: Essential Guidelines

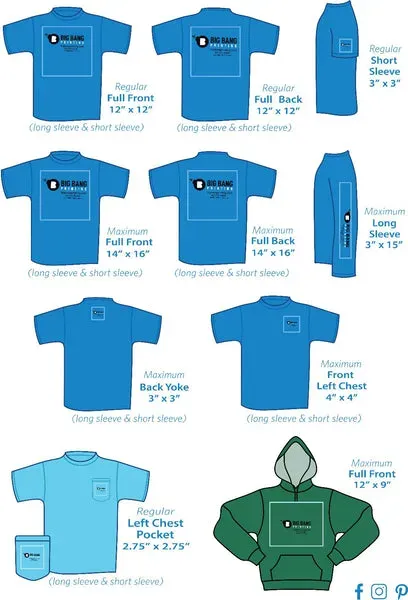

Understanding DTF transfers by size is critical for achieving optimal results in custom printing. The size of a transfer directly impacts the design’s visibility and the overall aesthetic appeal. Utilizing both standard sizes like 8×10 inches for smaller placements and 12×16 inches for visually striking designs ensures that the artwork fits well on the fabric without overpowering it. Furthermore, customized sizes can meet unique project demands, allowing businesses to tailor their offerings to meet specific customer needs.

In addition to selecting appropriate sizes, it’s vital to adhere to DTF transfer guidelines regarding design scaling. Altering a design’s dimensions can distort the visual quality, leading to unsatisfactory results. Maintaining proportions and aspect ratio is non-negotiable. When scaled correctly, images retain their integrity, presenting clear, vibrant prints on various materials. By focusing on size and proportion, printers can ensure that their DTF transfers not only look good but also function effectively on all fabric types.

The Role of Fabric in DTF Printing

The choice of fabric plays a significant role in the performance of DTF printing. Different materials pull ink in diverse ways, directly affecting the final print quality. Natural fibers like cotton may absorb ink differently than synthetic blends, requiring careful consideration of the transfer sizes and application methods. Understanding fabric properties, such as texture and absorbency, allows printers to adapt their techniques accordingly, optimizing the transfer process and achieving superior end results.

Furthermore, combining specific fabrics with DTF transfers can enhance the visual outcome. For instance, using a fabric that complements the vibrant colors produced by DTF printing can significantly amplify the appeal of the design. Additionally, being aware of how various fabric blends react can contribute to better adhesion and durability of the print. By aligning fabric choice with the intended application, printers can ensure that their products withstand the test of time, meeting the growing demands of custom apparel.

Recent Innovations in DTF Transfer Technology

The DTF printing landscape is continuously evolving, with recent innovations greatly enhancing the capabilities of custom apparel printing. Advancements in transfer film quality and ink formulation have led to improved adhesion and color vibrancy, allowing businesses to offer products that meet the increasingly sophisticated tastes of consumers. With high-resolution printing technology backing these developments, productions can cater to varying market demands efficiently.

Additionally, manufacturers are now incorporating eco-friendly materials into the DTF printing process, aligning with the growing sustainability trends. This shift not only appeals to environmentally conscious consumers but also presents an excellent opportunity for businesses to differentiate themselves in the marketplace. As technology progresses, staying informed about the latest innovations will be crucial for businesses looking to harness the full potential of DTF printing.

Navigating the E-Commerce Landscape with DTF Transfers

As e-commerce continues to boom, DTF transfers are becoming a cornerstone for businesses aiming to capitalize on the demand for customized products. The ability to offer unique, high-quality designs through DTF printing directly enhances the appeal of online shops. With consumers increasingly favoring personalized items, businesses that employ DTF transfers can meet this demand effectively, creating products that resonate with customers and encourage sales.

To navigate the e-commerce landscape successfully, businesses must focus on quality over quantity in their offerings. By utilizing high-resolution DTF printing technology and adhering to proper transfer size guidelines, companies can ensure that their printed products maintain a professional look. This commitment to quality not only builds brand loyalty but also helps in establishing a strong reputation in the custom apparel market, ultimately leading to sustained growth.

Best Practices for Effective DTF Transfer Printing

Implementing best practices is essential for businesses engaged in DTF transfer printing. From selecting the right equipment to ensuring compatibility with various fabrics, these practices are designed to foster efficiency and reliability in print quality. Investing in quality DTF printers and ink ensures that the final products are both vibrant and durable, meeting and exceeding customer expectations.

Moreover, troubleshooting and refining processes based on feedback and production outcomes can reveal invaluable insights. Regularly reviewing DTF transfer methods and adhering to manufacturer guidelines facilitates ongoing improvements. Continuous learning, experimentation with different materials, and staying updated with industry trends are key factors that will empower businesses to excel in the competitive landscape of custom apparel printing.

Frequently Asked Questions

What are the best practices for DTF transfers by size in custom apparel printing?

When optimizing DTF transfers by size, it’s essential to invest in high-quality printers and materials, maintain design resolution during scaling, and follow manufacturer guidelines for each fabric type. Experimenting with different transfer sizes can also improve outcomes.

How does transfer size impact DTF printing quality?

Transfer size directly influences print quality in DTF printing. Larger transfers may require higher resolution images to prevent blurriness, while also demanding specific techniques regarding heat and pressure settings for effective adhesion and durability.

What are the standard transfer sizes used in DTF printing?

In DTF printing, standard transfer sizes typically range from 8×10 inches for smaller designs to 12×16 inches for larger prints. Custom sizes are also available for unique printing needs, allowing for greater flexibility in design.

Why is understanding DTF transfer guidelines important when choosing sizes?

Understanding DTF transfer guidelines is crucial as they provide insight into how different sizes affect fabric type, design resolution, and printing technique. Adhering to these guidelines helps ensure successful application and high-quality results.

What recent trends influence DTF transfers by size in the printing industry?

Recent trends in DTF printing show increased integration into small and medium businesses, driven by the demand for customized products in e-commerce. Additionally, advancements in film quality and printing technology directly impact the effectiveness of various transfer sizes.

How can I maintain design proportions when scaling DTF transfers by size?

To maintain design proportions when scaling DTF transfers, ensure that the aspect ratio remains consistent during the resizing process. This practice will help keep the visual appeal and quality of the design intact across different transfer sizes.

| Aspect | Key Points |

|---|---|

| DTF Printing Overview | DTF transfers involve printing designs onto a film, which then transfers high-resolution prints onto diverse fabrics. |

| Advantages of DTF Transfers | Vibrant graphics, material versatility, and a soft finish make DTF an appealing choice for custom apparel. |

| Importance of Size | Correct sizing ensures print quality, design resolution, and fabric compatibility. |

| Sizing Guidelines | Common DTF sizes range from 8×10 to 12×16 inches, with custom sizes available. Maintain proper proportions for optimal results. |

| Current Trends | Increased DTF integration in businesses, driven by e-commerce demand and innovations in printing technology. |

| Best Practices | Invest in quality equipment, stay updated with design software, and follow manufacturer guidelines for best results. |

Summary

DTF Transfers by Size are fundamental for ensuring quality in the world of custom printing. As the custom apparel landscape evolves, understanding the nuances of DTF transfer sizing becomes essential for achieving stunning prints. From recognizing how design resolution affects size to implementing proper guidelines for layout and fabric choice, these factors are instrumental in delivering eye-catching results. By leveraging recent trends and adhering to best practices, businesses can enhance their printing capabilities, catering to the growing demand for high-quality custom apparel. Ultimately, knowledge of DTF transfers by size not only optimizes the printing process but also ensures creative designs shine on various fabrics.