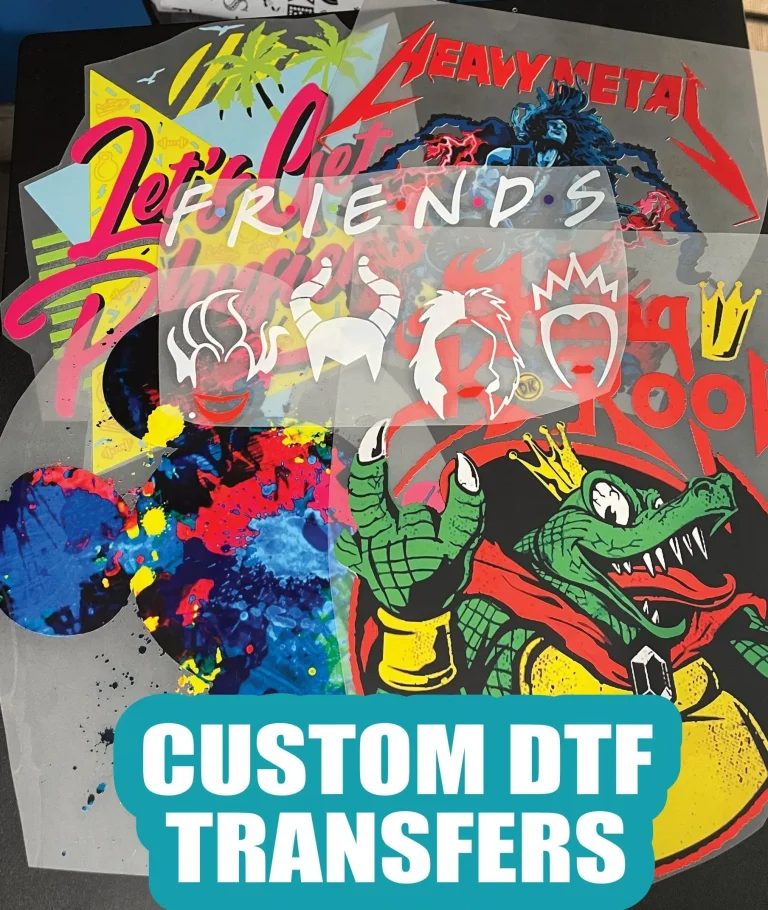

In the realm of custom apparel printing, **DTF transfers** (Direct-to-Film transfers) are revolutionizing the way designs are applied to fabrics. This innovative method allows for strikingly vibrant graphics and intricate details, but one critical element that can make or break the finish is the transfer size. Selecting the right DTF transfer sizing is essential not only for ensuring the best design clarity but also for achieving a professional look on various garments. In this guide, we will delve into how choosing the proper transfer size influences the overall quality and appeal of your printed apparel. With careful consideration of these factors, you can elevate your custom apparel projects and meet the expectations of your audience.

When it comes to applying high-quality images to fabric, techniques such as Direct-to-Film transfers have become increasingly popular among apparel manufacturers and creators. This method, often referred to as DTF printing, provides an exceptional depth of color and detail, making it a sought-after choice for producing customized clothing items. Choosing the right film transfer size is vital to maintaining the clarity of the design and ensuring a perfect application on the garment. Various printing approaches now emphasize the importance of optimal transfer dimensions to enhance the overall aesthetic and function. Understanding how to select the right size for your transfers can significantly impact the final presentation of your custom apparel.

The Impact of DTF Transfer Sizing on Design Clarity

When considering DTF transfers, one of the most critical factors is the transfer size, which has a direct impact on design clarity. Larger transfers allow for more intricate details to be visible, making the artwork vibrant and engaging, whether it’s a complex graphic or a text-heavy design. In contrast, smaller transfers can lead to a loss of detail, causing designs to appear pixelated or unclear when printed on fabric. Therefore, to enhance design clarity, it’s essential to choose a transfer size that complements the artwork itself.

In custom apparel printing, the ability to maximize design clarity is paramount. For instance, oversized graphics for t-shirts not only grab attention but also enable sophisticated designs with subtle gradients and fine details. Brands that prioritize the clarity of their prints often witness higher customer satisfaction, as vibrant and clear designs enhance the perceived value of the product. Hence, when selecting DTF transfer sizes, consider the complexity of your design to ensure it translates beautifully onto your apparel.

Choosing the Right DTF Transfer Size for Different Apparel Types

Different types of garments have varying requirements when it comes to transfer sizes. T-shirts usually provide ample space for larger designs, allowing for a standout graphic or brand logo that effectively showcases the apparel’s theme. In contrast, items like hoodies and jackets may not accommodate the same sized transfer due to their structure and fabric weight. Selecting the appropriate size not only enhances the visual appeal but also ensures the transfer adheres well without causing discomfort to the wearer.

For instance, a DTF transfer on a baseball cap would necessitate a smaller design, perhaps focusing on a logo or a small image, to fit properly and maintain the integrity of the cap’s shape. Similarly, when creating custom apparel for events, understanding the clothing’s cut and usage can influence the decision on transfer size. Thus, aligning the transfer’s dimensions with the specific garment type ensures that the finished product is not just visually appealing, but also well-fitted and functional.

Avoiding Distortion in DTF Transfers: Size Matters

When it comes to DTF transfers, size isn’t just about aesthetics; it’s also critical for preserving the integrity of your designs. Oversized transfers can lead to distortion during the heat-pressing process, which not only affects the appearance but can also diminish durability. A design that is supposed to maintain sharp edges may end up looking warped and unprofessional if the transfer size is not proportionate to the garment. Planning your design with size specifications in mind helps mitigate these risks.

Conducting sample tests can be tremendously beneficial in this regard. Testing various sizes on sample garments allows you to find the optimal footprint that preserves detail and prevents distortion. By understanding how different materials respond to varying transfer sizes, printers can achieve a better balance, ultimately resulting in high-quality output that meets customer expectations. This process reinforces the importance of proportions and careful planning in the selection of DTF transfer sizes.

Personalization Trends in DTF Transfer Sizing

The rise of personalization in custom apparel has significantly influenced DTF transfer sizing decisions. As consumers increasingly seek unique, personalized items—like shirts with custom names or numbers—size options become even more crucial. Brands must accommodate different designs and sizes, ensuring that each individual request is met with precision. This trend highlights the importance of flexibility in choosing transfer sizes that can effectively cater to diverse customer preferences.

Incorporating personalized elements into apparel not only enhances customer engagement but also drives loyalty. With DTF technology’s capability to provide vibrant and flawless prints, brands are positioned to offer tailored experiences that resonate with their audience. As such, understanding how to navigate transfer sizing in the context of personalization will be a key strategy for businesses looking to gain a competitive edge in the custom apparel market.

Staying Ahead with DTF Printing Innovations

As the DTF printing industry continues to evolve, staying ahead of trends related to transfer sizing is essential for businesses looking to thrive. Innovations in printing technology are paving the way for new materials and transfer techniques that not only improve the transfer sizes but also enhance the overall print quality. Future developments may include advances that allow for increased versatility in transfer dimensions, enabling some designs to be printed larger without compromising on clarity or durability.

Moreover, awareness of these innovations can help apparel brands anticipate shifts in consumer demand. Embracing new materials might lead to better adhesion properties, enabling the use of larger or more intricate designs that were previously unfeasible. By continually adapting to these advancements, businesses can improve their offerings and craft custom apparel that reflects current likes and preferences. Investing in knowledge about these trends is crucial for maintaining relevance in a dynamic market.

Understanding the Role of DTF Transfer Sizes in Marketing Strategies

In the competitive landscape of custom apparel, the choice of DTF transfer sizes can also play a pivotal role in marketing strategies. Large, eye-catching designs can serve more than just aesthetic purposes; they can become the focal point of marketing campaigns that capture attention on social media and in retail spaces. Effective marketing often hinges on how well products showcase their unique selling points, and print size can significantly affect this visibility.

Additionally, brands often implement sizing strategies that align with their target demographics. For vibrant, custom apparel tailored to youth culture, larger, bold designs may resonate better, while more refined, minimalist prints might appeal to mature audiences. Understanding these dynamics allows business owners to create tailored marketing messages that resonate not just in style but in substance, enhancing customer engagement and ultimately driving sales.

Frequently Asked Questions

What factors should I consider when choosing DTF transfer sizes for custom apparel printing?

When selecting DTF transfer sizes, consider your target audience and garment type. Different designs resonate better with specific demographics; for instance, children’s clothing often benefits from smaller, playful designs, while adult apparel may feature larger, more sophisticated logos. Matching the transfer size with the garment type, like using bigger designs on T-shirts and smaller ones on hoodies, is essential for maintaining design clarity and appeal.

How does DTF transfer sizing impact design clarity and visuals in custom apparel?

DTF transfer sizing significantly affects design clarity because larger transfers can showcase intricate details more effectively. When applying DTF transfers, a well-sized design maintains better visual impact and prevents distortion, which can occur with oversizing. To achieve stunning visuals, ensure that your transfer size complements the detail in your designs.

Can I customize the size of DTF transfers for different apparel styles?

Absolutely! Customizing the size of DTF transfers based on different apparel styles is a common practice in custom apparel printing. For example, use larger transfers for T-shirts to create bold statements, while smaller transfers work well for accents on sleeves or pockets. Tailoring transfer sizes allows for better design integration with various garment styles.

What are the common mistakes to avoid in DTF transfer sizing for apparel?

Common mistakes in DTF transfer sizing include choosing overly large transfers that could lead to distortion or poor fit on garments. Additionally, neglecting to test different sizes on sample fabrics can result in less desirable outcomes. Always consider proportions and the specific area of the garment where the transfer will be applied to avoid these pitfalls.

How do I determine the best transfer size for DTF printing in sports apparel?

When choosing DTF transfer sizes for sports apparel, aim for larger designs that ensure visibility during activities. Athletic wear often requires prominent logos or numbers that are easily seen from a distance. It’s essential to balance the transfer size with the garment’s structure to maintain design clarity and prevent distortion during wear.

What trends should I be aware of regarding DTF transfer sizing in custom apparel production?

Current trends in DTF transfer sizing focus on personalization and customer choice. As more brands offer customized products, providing a range of transfer sizes becomes crucial to meet diverse customer preferences. Additionally, advancements in DTF printing technology may allow for more flexible sizing options, enabling unique expressions through custom apparel designs.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers are popular for their vibrant designs in custom apparel printing. |

| Understanding DTF Transfers | DTF printing allows high customization, detailed, and durable prints. |

| Importance of Size | Transfer size affects design clarity and is crucial for different application areas. |

| Guidelines for Size Selection | Consider target audience, match size with garment type, avoid distortion. |

| Recommendations and Trends | Personalization trends and supplier insights advocate for diverse size offerings. |

| Future Developments | Expect more innovations in DTF technology to enhance size versatility. |

Summary

DTF transfers are an essential element in custom apparel printing, especially when it comes to enhancing the visual appeal of designs. Understanding the importance of transfer size can significantly impact design clarity and garment application. By thoughtfully selecting the right size based on your target audience and garment type, you can ensure that your DTF printed designs not only meet customer expectations but also stand out for their quality and durability. Adapting to emerging trends and advancements in technology will further maximize the effectiveness of your DTF transfers, setting your products apart in a competitive market.