DTF transfers, or Direct-to-Film transfers, are reshaping the landscape of custom apparel printing, providing a versatile and efficient solution for high-quality prints on a variety of fabrics. This innovative printing method not only delivers vibrant designs but also caters to diverse needs, making it a popular choice among both small businesses and established brands. To maximize the impact of your printed designs, understanding the different DTF transfer sizes is essential, as the appropriate size selection ensures that every detail of your graphic is showcased beautifully. Moreover, the benefits of DTF printing include its ability to produce intricate designs with excellent durability, which is particularly appealing for fashion-forward creators. As we explore DTF transfers in detail, we’ll uncover how choosing the right size can elevate your projects and help you stand out in the competitive market of custom apparel.

When it comes to advanced textile printing techniques, the term Direct-to-Film (DTF) encompasses a cutting-edge approach that is rapidly gaining traction for producing bespoke clothing designs. This method allows for high-resolution images to be transferred directly onto various fabric surfaces, enhancing the scope for creativity in fashion design. From personalized t-shirts to unique hoodies, employing DTF printing brings significant advantages, including durability and impressive color vibrancy. Understanding options like sizing and application area is crucial for designers who wish to leverage DTF technology effectively. Whether it’s for commercial ventures or personal projects, mastering the art of DTF transfers can lead to stunning and personalized apparel that captures the essence of individual style.

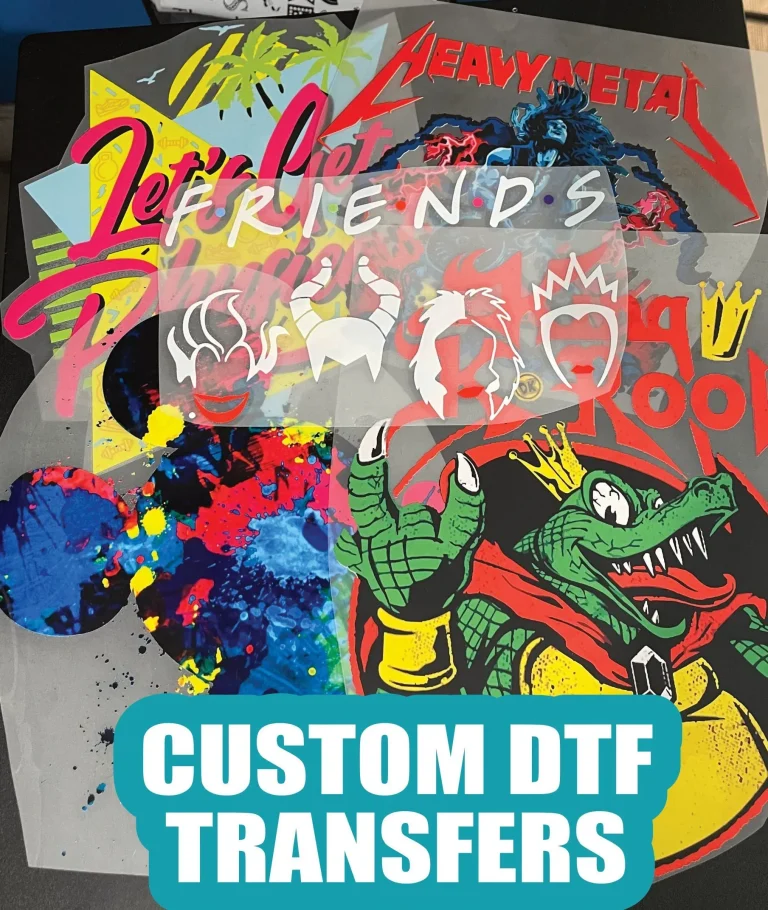

The Versatility of DTF Transfer Sizes

When it comes to custom apparel printing, DTF transfer sizes play a critical role in enhancing the overall aesthetics of your designs. Available in small, medium, and large options, DTF transfers allow for flexibility across a wide range of fabric types and clothing styles. For instance, small sizes are perfect for embroidery-like applications on caps or shirts, while medium and large sizes can accommodate full-spectrum designs that resonate with your target audience’s preferences.

The adaptability of DTF transfer sizes means that whether you are creating personalized promotional items or bespoke fashion pieces, you can find a size that perfectly complements your design. Understanding the specific nuances of each size will help you determine what best suits your project, enabling you to maximize the appeal of your printed products. This versatility is one of the primary reasons why more businesses are turning to DTF for their custom garment needs.

Understanding DTF Printing Benefits

DTF printing offers numerous benefits that distinguish it from traditional printing methods. High-quality prints with vibrant colors and intricate details are possible due to the innovative technology used in DTF transfers. The process involves printing designs directly onto a film, which is then transferred onto garments, resulting in long-lasting and durable outputs that withstand washing and wear.

The ability to create stunning visual effects with DTF printing attracts many creators and brands looking to stand out in competitive markets. Furthermore, DTF transfers allow for a great deal of customization, enabling businesses to offer unique products tailored to specific customer demands. With these advantages, it’s no surprise that many organizations are embracing DTF technology as a core component of their printing strategies.

How to Choose DTF Transfer Sizes Effectively

Choosing the right DTF transfer size is not just about aesthetics; it also requires careful consideration of the garment’s dimensions and style. The application area plays a significant role in this decision. For example, a large transfer on a small shirt can look overwhelming, while a small design on a larger garment may lose impact and visibility. Hence, assessing the proportions of your garment in relation to the transfer size is essential for achieving a balanced look.

Additionally, consider the design complexity when selecting DTF transfer sizes. More intricate designs benefit from being larger to capture all the details effectively, whereas simple designs might be enhanced when kept to a smaller scale. By testing your designs on fabric samples and analyzing how different sizes work with various materials, you can arrive at the best possible configuration that complements both your design and the intended application.

Trends in DTF Transfers for Custom Apparel

The rise of e-commerce and social media has significantly influenced market trends in custom apparel, with DTF transfers becoming increasingly popular. As fashion enthusiasts seek unique products, vendors are capitalizing on this trend by utilizing DTF technology to deliver personalized options that cater to diverse tastes. This shift emphasizes the importance of understanding transfer sizes, as creators aim to differentiate themselves in a saturated marketplace.

Moreover, the accessibility of DTF printing resources has allowed small businesses and independent creators to enter the market with unique designs. Trends indicate a preference for customization over mass production; hence, the ability to choose and utilize various DTF transfer sizes effectively positions brands to cater to consumer demands. This growing focus on personalized apparel highlights the importance of mastering DTF techniques to stay relevant and competitive.

Quality and Consistency in DTF Transfers

Quality control is paramount in DTF printing, particularly regarding transfer sizes. High-quality prints emerge from not only the precision of the printing technology but also the consistency in the size and application of transfers. Investing in quality materials for DTF transfers ensures that your final products meet the standards expected by customers, fostering trust and credibility in your brand.

It’s also crucial to maintain a uniform approach to DTF transfer sizes across different projects to achieve a cohesive look. When customers recognize a brand’s distinct style and quality, they are more likely to return for future purchases. Thus, managing quality while experimenting with sizes is a delicate balance that can significantly enhance customer satisfaction and loyalty.”}]} ,{

Maximizing DTF Printing Through Testing

Testing different DTF transfer sizes on various fabric types is a strategic approach that can lead to improved outcomes in custom apparel printing. By conducting tests, creators and manufacturers can determine which sizes work best for their specific designs and fabrics, ultimately saving time and resources in production. This practice allows for fine-tuning designs to ensure that they not only look great but also feel right when worn.

Incorporating feedback from sample testing can provide valuable insights into consumer preferences regarding DTF transfer sizes. This iterative process of prototyping leads to better decision-making in future projects, ensuring that sizes enhance the overall design rather than detract from it. By maximizing the effectiveness of DTF transfers through systematic testing, brands can elevate their product offerings to meet market demands.

Frequently Asked Questions

What are the benefits of using DTF transfers in custom apparel printing?

DTF transfers provide vibrant colors, durability, and versatility for custom apparel printing. They can be applied to various fabric types, ensuring high-quality prints that do not crack or fade with washing. Additionally, DTF printing allows for intricate designs and personalization, making it a top choice for both creators and businesses.

How do I choose the right size DTF transfer for my project?

When choosing the right size for your DTF transfer, consider the garment type and placement area. Smaller transfers (2″ to 4″) are ideal for logos on caps or sleeves, while medium sizes (5″ to 10″) suit t-shirts or hoodies. Large transfers (over 10″) are perfect for full-back designs. Always ensure your images have high resolution for the best quality prints.

What sizes are available for DTF transfers and how should I select them?

DTF transfers are available in small (2″ to 4″), medium (5″ to 10″), and large (over 10″) sizes. Choosing the right size depends on the design’s complexity and where it will be placed on the garment. Testing different sizes on fabric samples can help determine the best fit for your specific project.

What should I consider when designing with DTF transfers for custom apparel?

When designing for DTF transfers, consider the application area, image resolution (at least 300 DPI), and the intricacy of your design. Larger designs can showcase more details effectively, while simpler designs benefit from smaller sizes to enhance readability. Testing your designs on various sizes helps ensure optimal results.

Why are high-quality prints important in DTF transfers?

High-quality prints are crucial in DTF transfers because they ensure vivid colors and intricate details are maintained during application. Using high-resolution images prevents blurriness and loss of detail, thereby improving the overall aesthetic of your custom apparel. Investing in quality prints elevates your brand’s image and customer satisfaction.

How has the demand for DTF transfers changed in the custom apparel market?

The demand for DTF transfers in the custom apparel market has surged, especially among small businesses and independent designers. This printing method offers affordability and customization opportunities, allowing creators to cater to niche markets effectively. Brands can leverage DTF technology to produce unique designs that attract a specific audience.

| Size Range | Ideal Uses | Key Considerations |

|---|---|---|

| Small (2″ to 4″) | Logos, taglines on chest or sleeves, embellishments on hats | Best for simple and clear designs with high readability. |

| Medium (5″ to 10″) | Back designs on t-shirts, front graphics on hoodies | Maintaining high image resolution is crucial for quality. |

| Large (over 10″) | Full-back designs or big statement pieces on jackets | Allows for intricate details but requires careful placement assessment. |

Summary

DTF transfers are a game-changer in the world of textile printing, providing vibrant and high-quality solutions that cater to diverse projects. Understanding the significance of selecting the right sizes for your DTF transfers is crucial for achieving impactful designs. By choosing the appropriate size—whether small, medium, or large—you ensure that your graphics align perfectly with the intended application area and garment type, enhancing both aesthetics and readability. With the growing trend and demand for custom apparel, mastering DTF transfers not only enhances your creative projects but also positions you strategically within the competitive fashion industry.