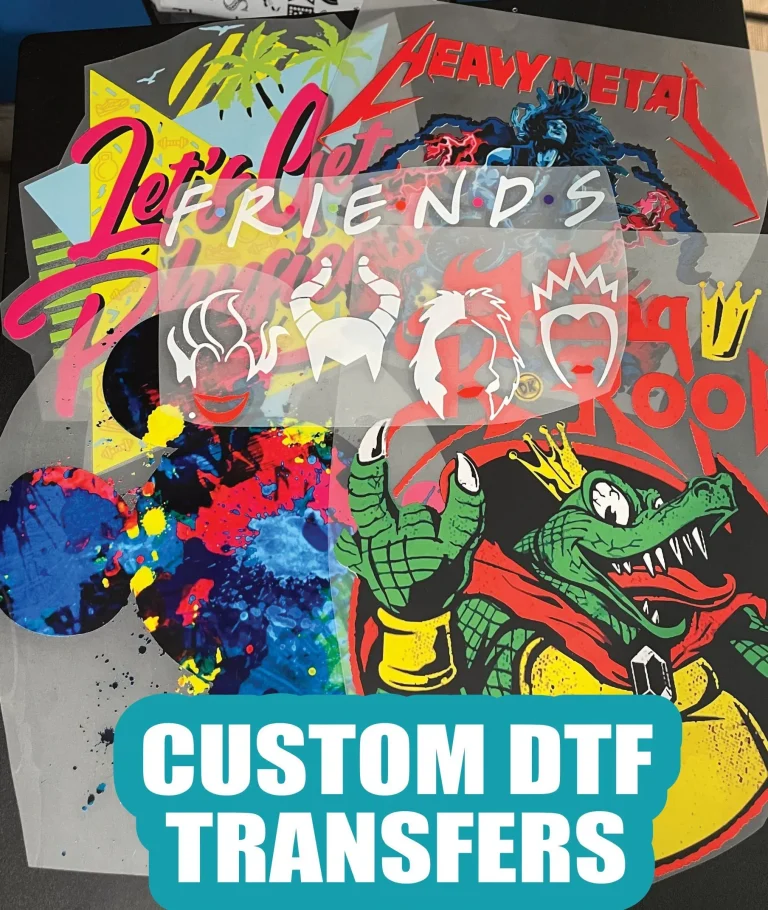

DTF Transfers, or Direct to Film transfers, represent a revolutionary approach to garment decoration, blending vibrant color output with efficiency. This innovative method not only enhances the quality of prints but also serves as a smarter alternative to traditional screen printing techniques. As this technology gains popularity, newcomers often encounter common pitfalls that can jeopardize the integrity of their prints. This guide aims to unravel those common DTF transfer mistakes, laying out essential strategies for achieving optimal results. By adhering to best practices in artwork preparation and application processes, you can elevate your DTF printing outcomes to the next level.

Direct to Film printing, commonly referred to as DTF transfers, is quickly becoming a staple in the world of textile design and fashion. This method allows for the detailed reproduction of artwork onto various fabric materials, producing eye-catching results that cater to diverse style preferences. However, as creatives delve into this exciting new technique, understanding the critical aspects associated with DTF printing can make a significant difference. From ensuring proper artwork preparation to mastering application tips, knowing how to navigate potential challenges is crucial for anyone looking to excel in the realm of textile prints. By exploring these nuances, professionals can avoid common DTF transfer mistakes and achieve stunning, long-lasting results.

Understanding Direct to Film Printing: The Basics

Direct to Film (DTF) printing is an innovative method that has revolutionized garment decoration. This process involves printing designs onto a special film, which is then transferred onto fabrics using heat and pressure. The appeal of DTF printing lies in its ability to produce vibrant colors and intricate designs, making it particularly popular among custom apparel creators. By leveraging the right tools and techniques, you can produce prints that not only stand out but also withstand the test of time.

What distinguishes DTF from traditional printing methods is its versatility. DTF transfers can be applied to a multitude of fabric types, including cotton, polyester, and blended materials. With the correct setup and knowledge, even intricate graphics can be transferred flawlessly. This process also eliminates many of the limitations posed by older methods, such as screen printing, which can struggle with detailed images or varying fabric blends.

Common DTF Transfer Mistakes and How to Avoid Them

Starting with DTF transfers can be exciting, but it’s crucial to be aware of common mistakes that may hinder your results. One frequent error is using low-quality images or inappropriate file formats, which can lead to pixelation and poor print quality. Always ensure your artwork is prepared correctly, utilizing high-resolution images and accepted formats like PNG or TIFF. This small step sets the foundation for achieving the best possible transfer outcomes.

Another universal mistake many new printers make is neglecting to adjust printer settings tailored for DTF transfers. Default printer settings may not yield the desired brightness or detail, which can lead to disappointing results. It’s imperative to familiarize yourself with your printer’s specifications and modify settings according to the media type and ink saturation. Paying attention to these details helps ensure that your final prints are vibrant and professional.

Importance of Testing Transfers on Various Fabrics

One often overlooked step in the DTF process is the necessity of testing transfers on different fabrics, which can significantly influence the outcome. Fabrics react differently to heat, adhesive application, and ink saturation, making preliminary tests essential. By testing on various materials, you can ascertain the best fabrics for your designs and avoid unexpected failures when applying the transfer to the final garment.

Conducting fabric tests also allows you to understand how well the colors hold up and how the transfers perform after washing. This knowledge is invaluable, as it informs future projects, helping you choose the right fabric right away. This proactive approach can enhance the quality of your DTF printing endeavors and lead to greater client satisfaction.

Mastering Curing Techniques for DTF Transfers

Curing is a critical yet often overlooked aspect of the DTF printing process that directly impacts the longevity and appearance of your transfers. Insufficient curing can lead to issues such as peeling, cracking, or fading of the prints, which are detrimental to any garment. Following the manufacturer’s guidelines for curing time and temperature is essential to ensure a strong bond between the transfer and the fabric, guaranteeing durability.

Implementing precise curing practices not only enhances the resilience of your prints but also promotes vibrant, stunning colors. Using temperature gauges and timers can assist in achieving consistent results. Mastering this step guarantees that you maximize the effectiveness of your DTF transfers while minimizing potential errors and material waste.

Post-Transfer Care: Ensuring Longevity of DTF Transfers

Once your DTF transfers are complete, it’s vital to provide your clients with clear guidance on post-transfer care. Neglecting this essential step can lead to rapid deterioration of the prints, ultimately resulting in dissatisfied customers. Crafting easy-to-follow care instructions—such as recommending cold washes and avoiding harsh chemicals—can significantly enhance the lifespan of the prints.

Informing customers about proper care practices ensures that they understand how to maintain their garments effectively. By taking the time to educate them on washing and drying methods, you contribute to preserving the integrity of DTF transfers while fostering customer satisfaction and trust in your printing services.

Best Practices for Successful DTF Printing

To achieve impressive results with DTF printing, adhering to best practices is crucial. Selecting high-quality films and inks ensures vibrant and lasting results. Additionally, maintaining proper printer maintenance and calibration helps avoid common errors that detract from print quality. Investing time to understand your equipment and materials can greatly enhance your printing capabilities.

Moreover, continuous learning and keeping abreast of industry trends and innovations can empower you to refine your DTF printing techniques. Engaging with online communities or forums allows you to share experiences and gather insights from other DTF enthusiasts, ultimately helping you to grow your skills and achieve excellence in your printing endeavors.

Frequently Asked Questions

What are common DTF transfer mistakes to avoid?

Common DTF transfer mistakes include inadequate artwork preparation, ignoring printer settings, and overlooking curing processes. These issues can lead to blurred prints, improper color transfer, and reduced durability. To avoid these pitfalls, ensure high-quality image resolutions, adjust printer settings for optimal performance, and follow proper curing guidelines.

How can I prepare artwork for DTF transfers effectively?

Effective artwork preparation for DTF transfers requires using high-resolution images (at least 300 DPI) and appropriate file formats like PNG or TIFF. This ensures that your designs are crisp and maintain quality throughout the printing process, leading to better results in Direct to Film printing.

What are the best practices for DTF printing?

The best practices for DTF printing include preparing high-quality artwork, familiarizing yourself with printer settings, performing test prints on various fabrics, ensuring proper curing temperatures and times, and providing customers with post-transfer care instructions to preserve the longevity of the DTF transfers.

Why is testing DTF transfers on different fabrics important?

Testing DTF transfers on different fabrics is crucial because each material can react differently to heat and adhesives. Conducting tests helps determine the best fabric for your designs, ensuring vibrant color transfer and durability, which are key aspects in successful DTF applications.

What tips can improve DTF application results?

To improve DTF application results, make sure to customize printer settings, thoroughly cure the prints as per manufacturer specifications, and avoid rushing the application process. Additionally, always perform tests to refine the technique and monitor how the transfer interacts with different textiles.

How should I care for garments after applying DTF transfers?

After applying DTF transfers, provide clear care instructions to your customers, emphasizing washing in cold water, avoiding bleach, and air-drying if possible. Such post-transfer care is essential to maintain the integrity and appearance of the DTF transfers, prolonging their lifespan.

| Common Mistakes | Description | Tips |

|---|---|---|

| Inadequate Preparation of Artwork | Failing to prepare artwork can lead to blurry prints. | Use high-resolution images (at least 300 DPI) and file formats like PNG or TIFF. |

| Ignoring the Correct Printer Settings | Default settings may not yield best results for DTF transfers. | Tailor printer settings for DTF including adjusting ink saturation and resolution. |

| Not Testing Transfers on Different Fabrics | Skipping testing can result in poor transfer application on garments. | Conduct tests on various fabric types to see how they react to DTF. |

| Overlooking the Importance of Curing | Insufficient curing can cause peeling or cracking of designs. | Follow manufacturer specifications for curing times and temperatures. |

| Neglecting Post-Transfer Care | Not providing care instructions can lead to rapid wear and tear. | Create clear care instructions focusing on wash and dry details. |

Summary

DTF Transfers are revolutionizing the world of garment decoration by providing vibrant and versatile printing options. However, to achieve the best results, it is crucial to avoid common mistakes that can compromise print quality. Attention to detail in artwork preparation, printer settings, testing fabrics, curing processes, and post-transfer care can significantly enhance the durability and appearance of your prints. By following best practices, anyone can successfully navigate the DTF printing landscape and produce stunning, lasting designs.