DTF transfers are revolutionizing the apparel printing landscape by offering a versatile and high-quality solution for designers and businesses alike. This innovative printing method utilizes a unique process that applies vivid designs onto a variety of fabrics, making it a strong alternative to traditional techniques such as Direct-to-Garment (DTG) printing and screen printing. Unlike methods like heat transfer vinyl (HTV), DTF transfers promise enhanced durability and color vibrancy, catering perfectly to the growing demand for custom printing solutions. As industries increasingly seek efficient and reliable fabric printing techniques, understanding the advantages of DTF transfers is essential for making informed choices. In this exploration, we’ll delve into how DTF compares with other popular printing methods, guiding you to the best options for your creative projects.

Referred to as Direct-to-Film printing, DTF is capturing the attention of many within the custom apparel realm thanks to its adaptability and superior output. This method shines when matched against other fabric printing techniques, including Direct-to-Garment (DTG) and traditional screen printing. By leveraging a unique process to transfer designs onto various textiles, businesses can unlock a plethora of design possibilities. Whether considering screen printing’s bulk efficiency or the simplicity of heat transfer vinyl (HTV), assessing the merits of DTF is vital for creators seeking quality and customization. This discussion will reveal why DTF stands out in a competitive market, enriching your understanding of modern printing methods.

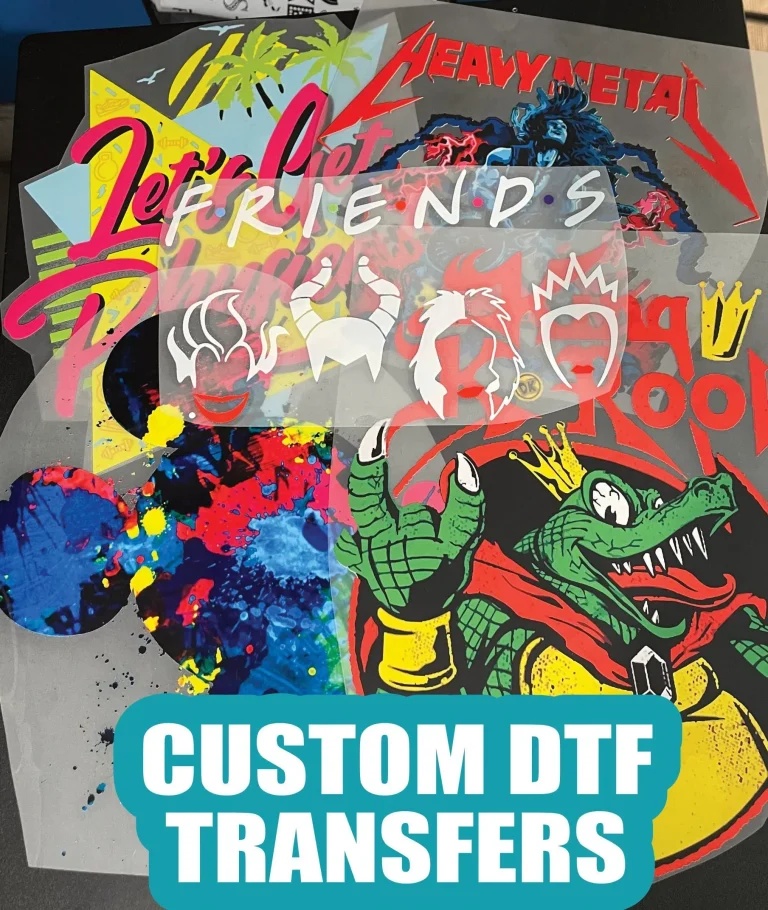

The Rise of DTF Transfers in Custom Printing

In the competitive landscape of custom printing, DTF transfers are emerging as a game changer. This innovative technology allows for vibrant, high-quality prints on a variety of fabrics, making it a go-to for apparel decorators seeking versatility. Unlike traditional methods that often require extensive setup or specialized equipment, DTF printing simplifies the process, enabling quick adaptations to changing trends in fashion and personal expression. As a result, businesses can efficiently cater to their customers’ needs, whether for personalized t-shirts, intricate designs on hoodies, or detailed graphics on sports apparel.

Moreover, the benefits of DTF transfers extend beyond just aesthetics. The method produces prints that are durable and resistant to wear over time. Unlike Direct-to-Garment (DTG) printing, which can struggle with fabric gels and fading, DTF methods bond effectively to a wider range of textiles, ensuring longevity. This characteristic is especially critical for businesses aiming for customer satisfaction and repeat business, reinforcing DTF’s position as a top choice in the realm of custom printing.

Comparative Benefits of DTF Transfers and DTG Printing

When evaluating printing methods, the comparison between DTF transfers and Direct-to-Garment (DTG) printing is particularly enlightening. While DTG is well-known for its detailed imaging capabilities directly on garments, it is often limited to natural fibers like cotton. DTF transfers, however, open up a world of possibilities by being compatible with various fabric types, including polyester and fabric blends. This adaptability is essential for businesses looking to produce diverse product lines without worrying about material constraints.

Additionally, cost-effectiveness remains a critical factor when choosing between DTF and DTG. DTF transfers eliminate the need for expensive screen setups and extensive initial investments required for DTG printing. For small to medium print runs, DTF offers a more economical solution, allowing businesses to maximize their profit margins while also being agile enough to respond to fast-paced market demands. Therefore, for companies that prioritize both quality and cost-efficiency, DTF printing stands out as the preferable option.

Exploring DTF Transfers Versus Screen Printing

Screen printing has long been the standard for producing large batches of apparel, but the emergence of DTF transfers is reshaping this landscape. One of the most significant advantages DTF printing holds over traditional screen printing is its ease of use. While screen printing requires meticulous setup and may involve labor-intensive processes, DTF simplifies production with a quicker, more efficient method. This is particularly beneficial for businesses needing on-demand services or quick turnaround times, allowing them to meet client requests with unparalleled speed.

Furthermore, DTF’s versatility in terms of material compatibility greatly surpasses that of screen printing. Although screen printing excels in large production runs, it often falls short when handling specialty fabrics or complex designs. DTF transfers, on the other hand, accommodate a variety of fabric types, from cotton and polyester to intricate blends. This flexibility enables businesses to cater to a broader customer base looking for customized designs across different apparel styles, enhancing their overall service offering.

Advantages of DTF Transfers Over Heat Transfer Vinyl (HTV)

DTF transfers provide distinct advantages when compared to Heat Transfer Vinyl (HTV), particularly regarding material compatibility and design complexity. While HTV tends to have limitations in terms of the types of fabrics it can bond with effectively, DTF transfers can be applied effortlessly across a spectrum of fabric types, thereby accommodating diverse apparel needs. This capability is paramount for businesses that wish to offer varied products to their clientele without the constraints imposed by vinyl materials.

In terms of output quality, DTF transfers often yield more vibrant and intricate designs than HTV can achieve. This is due to the unique printing process utilized in DTF production, which allows for photorealistic images and elaborate graphics that stand out on apparel. Unlike HTV options, which can feel bulky and weigh down the fabric, DTF prints maintain a soft and comfortable texture, making them more appealing to end consumers. For companies prioritizing quality and customer satisfaction, DTF presents invaluable advantages over Heat Transfer Vinyl.

Cost-Efficiency of DTF Transfers

The financial implications of choosing a printing method cannot be overstated. DTF transfers offer a cost-efficient alternative compared to traditional methods like DTG and screen printing, especially for businesses that operate on a smaller scale. With lower overhead costs and the absence of different setup fees involved in screen printing, businesses can adjust their pricing strategies to remain competitive while still profiting from their work. This ability to reduce costs without sacrificing quality is particularly vital in a market increasingly defined by personalized and custom printing.

Moreover, by embracing DTF technology, small businesses can engage in short-run printing more profitably. This technique minimizes waste associated with oversized bulk orders typical in older methods. As consumer demand shifts towards more unique, one-of-a-kind items, DTF printing allows businesses to respond flexibly without compromising financial viability, thereby solidifying its place as a preferred method amongst cost-conscious decorators.

Future Outlook for DTF Printing in the Industry

The future of DTF printing looks promising, as advancements in technology and growing market demand for customization continue to drive its adoption. As manufacturers refine their processes and develop more advanced inks and adhesives, the quality and durability of DTF prints are expected to improve even further. This constant evolution positions DTF printing not only as a viable option but also as a leading solution for custom apparel, surpassing even the well-established methods of DTG and screen printing.

Furthermore, as eco-friendly practices gain traction in the garment industry, DTF printing aligns well with these values. Its efficient use of materials minimizes waste during the production process, appealing to environmentally conscious consumers. This focus on sustainability could propel DTF printing into an even more favorable spotlight, making it the go-to method for businesses looking to combine quality, cost-effectiveness, and environmental responsibility. Ultimately, DTF technology might just redefine the standards for custom printing in the years to come.

Frequently Asked Questions

What are DTF transfers and how do they compare to traditional printing methods?

DTF transfers, or Direct-to-Film transfers, utilize a specialized printing process where designs are printed on a PET film before being transferred onto fabric using a heat press. Compared to traditional methods like Direct-to-Garment (DTG) printing and Screen printing, DTF offers greater versatility for various materials, superior durability, and lower costs for smaller runs.

Are DTF transfers more cost-effective than DTG printing for custom designs?

Yes, DTF transfers are often more cost-effective than DTG printing for custom designs, especially for small to medium-sized orders. DTF does not require expensive equipment or setup fees associated with DTG processes, making it an ideal choice for businesses looking for efficient and affordable customized prints.

How does the durability of DTF transfers measure against screen printing?

DTF transfers are recognized for their durability, often surpassing that of screen printing. Because the DTF process involves a unique adhesive and ink that bond effectively with fabrics, DTF prints can withstand more wash cycles without fading or peeling, making them a reliable choice for long-lasting apparel.

What types of fabrics are compatible with DTF transfers versus heat transfer vinyl (HTV)?

DTF transfers are compatible with a wide range of fabrics, including cotton, polyester, and blends, making them versatile for various applications. In contrast, HTV is more limited in compatibility and may struggle with delicate or complex fabric types, thereby making DTF a preferable choice for diverse fabric printing needs.

What advantages do DTF transfers offer over traditional screen printing?

DTF transfers provide several advantages over traditional screen printing, including easier setup, faster production times, and compatibility with a broader range of materials. Unlike screen printing, which can be labor-intensive and requires detailed setups, DTF printing streamlines the process, making it ideal for on-demand printing and custom designs.

Can I achieve vibrant colors with DTF transfers like I can with DTG printing?

Yes, DTF transfers can achieve vibrant colors comparable to DTG printing. The process utilizes high-quality inks and an effective transfer method that enhances color vibrancy, ensuring that the final product has the same eye-catching appearance as designs printed using Direct-to-Garment techniques.

| Printing Technique | Process Overview | Durability and Quality | Cost-Effectiveness | Versatility | Ease of Use |

|---|---|---|---|---|---|

| DTF Transfers | Design printed on PET film; applied to fabric using heat press. | Highly durable; vibrant colors; better for multiple washes compared to DTG. | More economical for small to medium runs; lower investment costs. | Works on various fabric types including cotton and polyester blends. | Easier to set up and quick for on-demand production. |

Summary

DTF Transfers are revolutionizing the printing landscape by providing superior quality, durability, and cost-effectiveness. This method stands out among traditional techniques such as DTG printing, screen printing, and heat transfer vinyl (HTV), particularly for those looking to produce vibrant, customized designs on diverse fabrics. With the growing demand for personalization in the apparel market, DTF technology offers an accessible and efficient solution for both small businesses and individual creators. As advancements continue to enhance DTF capabilities, it positions itself as a leading choice for effective fabric printing solutions.