DTF transfers, or Direct-to-Film transfers, have quickly gained notoriety in the world of custom apparel printing for their impressive versatility and quality. Unlike traditional methods like screen printing and sublimation printing, DTF printing stands out by allowing intricate designs and vibrant colors to be transferred onto a variety of fabric types, including dark materials. This makes it a prime choice for entrepreneurs looking to create unique clothing items that cater to diverse customer preferences. In the following sections, we will delve deeper into how DTF transfers compare with other popular printing techniques such as Direct-to-Garment (DTG) printing and heat transfer methods. By the end of this discussion, you will be well on your way to selecting the ideal printing method for your creative projects.

When it comes to fabric decoration techniques, Direct-to-Film (DTF) transfers represent a cutting-edge approach to printing designs onto garments. This innovative method simplifies the application of colorful and complex graphics, making it a strong competitor against more established favorites, such as screen printing and sublimation. Moreover, DTF printing excels in performance across various fabric types, which positions it favorably in the realm of custom apparel printing. As we explore DTF and its counterparts further, such as DTG and screen printing, you’ll discover the unique benefits and limitations that can influence your choice for garment customization. Engaging with these diverse printing solutions can ultimately enhance your ability to create standout apparel.

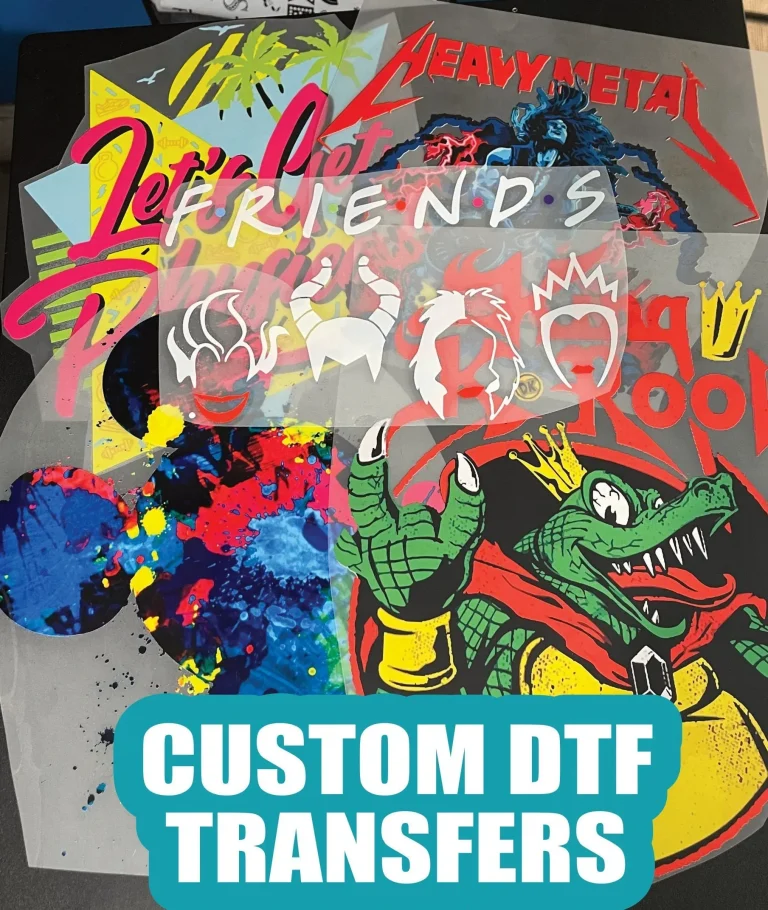

The Rise of DTF Transfers in Custom Apparel Printing

Over recent years, Direct-to-Film (DTF) transfers have gained significant traction within the custom apparel printing industry. This method streamlines the transfer process by utilizing specialized film, which allows for intricate designs to be printed with remarkable clarity. DTF excels where traditional printing methods often fall short, especially in terms of versatility across various fabric types, including both light and dark materials. As businesses look to differentiate their offerings in a competitive market, DTF provides an innovative approach that resonates with both customers and creators alike.

The popularity of DTF transfers has been further bolstered by advancements in printing technology, enabling users to achieve high-resolution images that maintain vibrancy even after multiple washes. As more entrepreneurs venture into the realm of custom apparel, adopting DTF printing can be a strategic move that caters to diverse market demands. In a landscape where customization is king, the flexibility offered by DTF serves not just small business owners but also larger scale operations looking to diversify their product lines.

Why Choose DTF Transfers Over Screen Printing?

When comparing DTF transfers to screen printing, several key advantages emerge that may influence your decision. Screen printing has long been celebrated for its durability and color richness, particularly in large batch productions. However, it often involves a lengthy setup process and can struggle with complex designs or smaller print runs. Conversely, DTF printing can easily accommodate detailed artwork with multiple colors without these constraints, making it an ideal choice for businesses that prioritize both quality and efficiency.

Another notable point is the fabric compatibility that DTF affords. While screen printing primarily excels on flat cotton surfaces, DTF adapts seamlessly to an array of fabrics, including blends and polyester, which opens the door to various creative possibilities. This means custom apparel designers can experiment with different materials and looks, giving them a competitive edge. As brands look to offer unique, eye-catching products, DTF transfers stand out as a modern solution for intricate and high-quality prints.

Understanding the Quality of DTF Printing Compared to DTG

Direct-to-Garment (DTG) printing is often praised for its ability to deliver stunning detail and an effortless user experience. However, it is largely limited to cotton fabrics and struggles with dark garments. In contrast, DTF printing shines by providing exceptional quality across a broader spectrum of materials, allowing for vibrant, high-resolution designs regardless of the fabric type. This flexibility makes DTF a superior choice for custom projects requiring diversification in materials and print quality.

Furthermore, it’s important to note that DTF prints are known for their durability, outperforming many DTG prints when it comes to longevity. DTF transfers maintain their color vibrancy and resist fading even after repeated laundering, making them particularly appealing for brands that emphasize quality in their apparel. The capacity to produce intricate designs on various fabric types without sacrificing quality sets DTF apart as a frontrunner in custom apparel printing.

Sublimation Printing vs. DTF Transfers: Key Differences

Sublimation printing has established itself as a favorite for all-over designs, particularly on polyester fabrics. However, it has limitations, mainly requiring light-colored materials to achieve vibrant results. DTF printing, on the other hand, excels in versatility, allowing artists and businesses to print on both dark and light fabrics without compromising on color depth or detail. This attribute significantly broadens the scope for creative applications, such as making unique apparel that caters to specific customer preferences.

Moreover, the application process of DTF transfers provides a more user-friendly experience when compared to sublimation, which often necessitates specialized inks and equipment. DTF can be executed efficiently with straightforward techniques, reducing both time and cost for users, especially those venturing into custom printing for the first time. As such, DTF printing not only matches but often surpasses sublimation in terms of adaptability for creative projects.

Cost-Effectiveness of DTF Transfers for Small Businesses

When evaluating the cost-effectiveness of various printing methods, DTF transfers present a compelling argument for small business owners. Unlike heavy investment-backed screen printing setups that benefit bulk orders, DTF is ideal for small to medium production runs, allowing entrepreneurs to create high-quality custom apparel without excessive upfront costs. This particular advantage enables new businesses to test various designs and markets without committing to large inventories.

Additionally, the reduction of waste is another financial benefit with DTF printing. Since this method allows for printing on demand and efficiently reduces setup times, businesses can avoid overproduction, which can be detrimental in today’s fast-paced fashion landscape. With DTF transfers, small brands can swiftly adapt to changing market trends, providing them with the agility needed to thrive in a competitive environment.

Choosing the Right Printing Method: Factors to Consider

Choosing the most suitable printing method can feel overwhelming without a clear understanding of your specific needs. Factors such as the types of fabric you wish to work with, the complexity of your designs, and the anticipated production volume all play crucial roles in determining whether DTF, screen printing, sublimation, or DTG would be the best fit. For instance, if you plan to print on a wider variety of fabrics, DTF is likely the most recommended solution due to its adaptability.

Design complexity is another critical consideration. While screen printing may offer durability for straightforward designs, it may falter with intricate artwork that DTF handles effortlessly. Moreover, businesses must factor in production variables; if smaller, custom runs are your focus, DTF offers a practical approach without the scalability issues that traditional methods may pose. Weighing these considerations will help you make a confident decision that aligns with both your creative vision and operational goals.

Frequently Asked Questions

What are DTF transfers in custom apparel printing?

Direct-to-Film (DTF) transfers are a modern printing method where designs are printed onto a special film, which is then transferred onto garments using heat and pressure. This method allows for high-quality images to be applied to a variety of fabrics, making it popular among custom apparel printing enthusiasts.

How do DTF transfers compare to Direct-to-Garment (DTG) printing?

DTF transfers have the advantage of being compatible with a wider range of fabric types, including polyester and dark materials, whereas DTG printing is primarily effective on 100% cotton. This versatility makes DTF a better choice for projects requiring various materials.

Are DTF transfers more durable than screen printing?

Yes, DTF transfers are known for their durability and can withstand multiple wash cycles without fading or cracking, often outperforming screen printing in terms of longevity, especially for garments intended for everyday wear.

What type of designs are best suited for DTF transfers versus sublimation printing?

DTF transfers excel at reproducing intricate multi-color designs, making them ideal for detailed projects. In contrast, sublimation printing is limited to lighter fabrics, which can restrict design options. DTF allows vibrant printing on dark materials without sacrificing quality.

Can DTF transfers be used for small batch orders effectively?

Absolutely! DTF transfers are well-suited for small batch orders, offering high-quality results without the economical constraints often associated with screen printing, which is better for bulk production.

What should I consider when choosing between DTF transfers and other printing methods?

Consider the types of fabrics you will use, the complexity of your designs, production volume, and the expected lifespan of your apparel. DTF transfers are versatile, support detailed designs, and offer excellent durability, making them a well-rounded option for various printing needs.

| Printing Method | Fabric Compatibility | Durability | Design Complexity | Best Use Cases |

|---|---|---|---|---|

| DTF Transfers | Polyester, blends, dark fabrics | High durability, withstands many washes | Excellent for intricate designs | Small to medium batch orders, complex designs |

| Screen Printing | Mostly cotton, limited on other fabrics | Durable but can feel heavy on fabric | Good for simple designs | Large bulk orders |

| Direct-to-Garment (DTG) | Primarily on cotton fabrics | Good, but more susceptible to fading | High-quality for simple to complex designs | Single or small runs on cotton shirts |

| Sublimation Printing | Best on polyester, limited by color of fabric | High durability on treated fabrics | Good for detailed medium designs | All-over prints on light-colored fabrics |

Summary

DTF transfers have surged to the forefront as a go-to solution in custom apparel printing. With their remarkable versatility and high-quality finish, DTF transfers deliver on a promise of durability that surpasses many traditional methods. Whether you are a business aiming for unique, durable custom designs or a hobbyist enthusiastic about bringing creative visions to life, exploring DTF transfers will undoubtedly enhance your printing capabilities. This method not only accommodates a wider variety of fabrics but also excels with intricate designs, making it an exceptional choice in today’s competitive market.