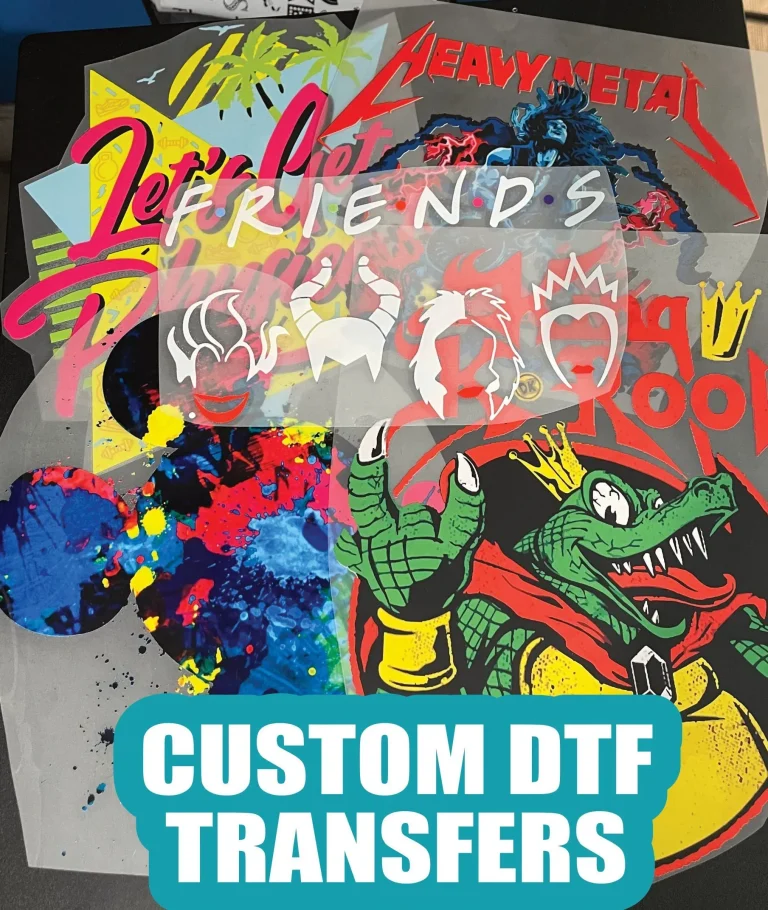

DTF transfers, short for Direct to Film transfers, are revolutionizing the custom apparel and fabric printing landscape. This cutting-edge print technology provides a reliable and efficient way to create stunning designs that can be transferred effortlessly onto various fabric types. As more businesses and creatives seek unique customization options, DTF printing has emerged as a preferred method, offering vibrant colors and impressive durability. The simplicity of the DTF transfer process, combined with its ability to cater to both large-scale productions and one-off custom pieces, makes it an attractive choice for anyone involved in textile decoration. In this article, we delve deeper into DTF transfers, addressing common queries that surround this innovative printing technique.

Also referred to as Direct to Film printing, this advanced method represents a significant leap in fabric decoration technologies. Often discussed alongside other techniques such as heat transfer printing and direct-to-garment applications, DTF transfers stand out due to their versatility across different surfaces. The process involves applying prints onto a film which, when heated and pressed, transfers into the fabric, allowing for custom apparel creation that meets modern demands. By exploring the advantages of this print technology, including its capacity for brilliant designs and durability across various material blends, it becomes clear why DTF is gaining traction among both professional and aspiring designers.

Understanding the DTF Printing Process

The DTF printing process is an innovative method that has revolutionized the custom apparel industry. It begins with creating a design on specialized DTF film using a printer specifically engineered for this purpose. The film is coated with a unique adhesive that bonds with textile materials once heat is applied. This process not only ensures that vibrant colors are captured accurately but also allows for detailed designs to be printed, making DTF a preferred choice over traditional printing methods.

Following the initial printing stage, a powdered adhesive is sprinkled onto the wet ink. After this, the film undergoes curing, which sets the adhesive and prepares the design for transfer. The culmination of this process is the transfer itself, where the film is pressed onto the fabric using a heat press. This pressure and heat activate the adhesive, binding the ink to the fabric firmly. The versatility of DTF printing allows for its application on various fabric types, including cotton and polyester, accommodating a range of custom apparel needs.

Benefits of Choosing DTF Transfers for Custom Apparel

DTF transfers offer numerous advantages that make them appealing for custom apparel projects. One of the most notable benefits is the versatility of the method; DTF can be applied to multiple fabric types, providing decorators with the freedom to experiment with different materials. This adaptability makes DTF an excellent option for businesses that wish to diversify their product offerings beyond just cotton garments. Furthermore, the high-quality prints produced through DTF exhibit vivid colors and sharp details, enhancing the overall aesthetic of custom designs.

Additionally, DTF prints are recognized for their durability. Unlike some other printing techniques, DTF transfers can withstand multiple washes without fading or degrading in quality. This aspect significantly contributes to consumer satisfaction, as customers are inclined to choose apparel that maintains its quality over time. Lastly, the cost-effectiveness of DTF printing stands out, especially when producing small runs or individualized orders, making it a smart choice for both businesses and hobbyists looking to deliver quality products without excessive costs.

Common Queries About DTF Transfers

Many potential users often express curiosity about whether DTF transfers are practical for everyday wear, especially concerning washing and drying. Thankfully, when DTF prints are correctly applied and cured, they are designed to withstand regular laundering. It’s recommended that garments featuring DTF prints be washed inside out on gentle cycles to extend their lifespan. This durability has encouraged businesses to adopt DTF methods, ensuring that their products maintain a fresh appearance even after repeated use.

Another common question revolves around the equipment necessary for executing DTF transfers effectively. The primary requirements include a dedicated DTF printer, a heat press, and the appropriate films and powders. Investing in DTF printer technology tailored for this process can dramatically improve results and efficiency. For beginners, many suppliers now offer comprehensive starter kits that include everything needed to embark on their DTF printing journey, simplifying the initial setup and enabling more individuals to explore this exciting print technology.

Environmental Considerations in DTF Printing

As sustainability becomes increasingly vital in manufacturing, many are curious about the environmental impact of DTF transfers compared to traditional printing methods. Generally, DTF printing generates less waste due to its streamlined process, as it allows for precise printing directly onto the film. This efficiency can reduce the amount of ink and materials that typically go to waste in other methods like screen printing. However, the eco-friendliness of DTF printing heavily relies on the inks and adhesives used.

To mitigate environmental concerns, it is crucial to seek out suppliers that focus on sustainable materials for DTF printing. Many companies are striving to develop inks and powders that are less harmful to the environment, signaling progress in the industry. Adopting eco-friendly practices in your DTF printing endeavors not only aids in reducing waste but can also enhance your brand’s appeal to conscious consumers, making it a win-win in the competitive custom apparel market.

Keeping Up with DTF Printing Trends

The landscape of DTF printing is continually evolving, with ongoing advancements in ink formulations and film technologies. These innovations have led to enhanced print performance, allowing for even greater detail and color vibrancy. As DTF printing gains traction in the custom apparel sector, keeping abreast of the latest trends and developments is crucial for anyone looking to capitalize on this technology. Engaging with industry news sources and participating in related online forums can provide valuable insights into emerging best practices and tools.

Moreover, the rise of e-commerce has been a game-changer for DTF printing businesses, enabling greater customization in order fulfillment. This shift means that sellers can now offer an even more personalized experience, tapping into the growing consumer demand for unique and tailored products. Thus, staying informed about e-commerce integration with DTF technology can help businesses not only improve their operational efficiency but also expand their market reach within the competitive industry.

Begin Your DTF Printing Journey Today

For those looking to dive into DTF printing, there are abundant resources to guide you through the starting process. One of the first steps is to research and choose suppliers that offer equipment bundles specifically designed for DTF printing. These kits often contain printers, heat presses, and the necessary materials, making it simpler for newcomers to get set up. Platforms such as Printful and ProWorld provide comprehensive guides and tutorials to help users understand the nuances of DTF printing.

Additionally, engaging with community forums and social media groups can provide additional support for beginners. Users share their experiences, tips, and creative ideas, fostering an environment of learning and collaboration. Online video tutorials, particularly on platforms like YouTube, further enhance this learning experience, allowing visual learners to see the DTF process in action. By leveraging these resources, aspiring DTF printers can equip themselves with the knowledge and tools needed to excel in their creative projects.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is an innovative fabric printing technique that allows users to print designs on a special film coated with an adhesive, which is then transferred onto fabric using heat and pressure. This process is versatile, enabling printing on a variety of materials such as cotton and polyester, ideal for custom apparel.

What equipment do I need for DTF transfers?

To start with DTF transfers, you’ll need a DTF printer that uses specialized inks, a heat press for applying heat and pressure for transfers, and DTF transfer film and powder. Many suppliers offer complete kits to simplify the setup for beginners.

Are DTF transfers suitable for all fabric types?

Yes, DTF transfers are highly versatile and can be applied to a wide range of fabric types including cotton, polyester, and blends. This flexibility makes DTF printing an excellent choice for diverse custom apparel projects.

How durable are DTF prints after washing?

DTF prints are designed to be durable and withstand regular washing when properly cured. It’s recommended to wash printed fabrics inside out and use gentle cycles to maintain the quality and longevity of your designs.

Is DTF printing more cost-effective than traditional screen printing?

Yes, DTF printing is often more cost-effective for smaller runs or custom orders, unlike screen printing which requires a larger quantity to offset setup costs. DTF allows for economical small batch production without compromising on quality.

What are the environmental impacts of DTF transfers?

The environmental impact of DTF transfers varies based on the inks and powders used. While DTF printing can produce less waste compared to traditional methods, it’s important to research and select eco-friendly materials and practices to minimize your environmental footprint.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing a design onto a special film, applying a powdered adhesive, curing it, and transferring to fabric using a heat press. |

| Advantages of DTF Transfers | 1. Versatility: Can be used on multiple fabric types. 2. Quality: High resolution and vibrant colors. 3. Durability: Wash-resistant and flexible prints. 4. Cost-Effectiveness: Economical for small production runs. |

| Common Questions | 1. Can DTF transfers be washed and dried normally? – Yes, they withstand regular washing and should be washed inside out. 2. What equipment is needed? – A specialized DTF printer, heat press, transfer film, and powder. 3. Are DTF transfers environmentally friendly? – Impact varies; research eco-friendly materials. |

| Recent Developments | Innovations in ink formulations and film technology are improving performance, and integration with e-commerce platforms is on the rise. |

| Getting Started with DTF Printing | Research suppliers for equipment bundles, utilize online forums, and watch tutorials for best practices. |

Summary

DTF transfers represent a revolutionary printing option that combines versatility with innovation, making it a standout choice for creators in the custom apparel industry. With a unique process that involves printing on film and transferring designs with heat, DTF transfers allow for vibrant and durable applications on various fabric types. This method not only meets the needs of both large-scale production and personal projects but also offers substantial advantages in quality and cost-effectiveness. As DTF printing technology continues to evolve, it promises an exciting future for custom apparel decoration.