In the ever-evolving landscape of textile printing, DTF transfers have emerged as a revolutionary technique that combines efficiency with exceptional quality. With the rise of the digital age, DTF printing has captured the attention of small business owners and fashion designers alike. One of the main advantages of DTF is its ability to produce high-quality textile prints that showcase intricate designs and vibrant colors, making it a top choice for custom merchandise. Furthermore, it caters to the growing demand for eco-friendly printing solutions, utilizing water-based inks that lessen environmental impact. Whether for personalized apparel or promotional items, DTF transfers serve as a cost-effective printing solution, bridging the gap between creativity and sustainability.

Direct-to-Film printing technology, often referred to as DTF, represents a significant advancement in the realm of garment printing. This method allows for the transfer of printed images onto various textiles, resulting in eye-catching designs that are both durable and precise. As awareness of sustainable printing practices grows, the eco-friendly components associated with this process, such as water-based inks, have gained traction among consumers. Transitioning to DTF methods can prove to be a cost-effective alternative to traditional printing techniques, facilitating swift production times while maintaining high standards. Embracing DTF transfers opens up a world of possibilities for both creators and businesses in the competitive apparel market.

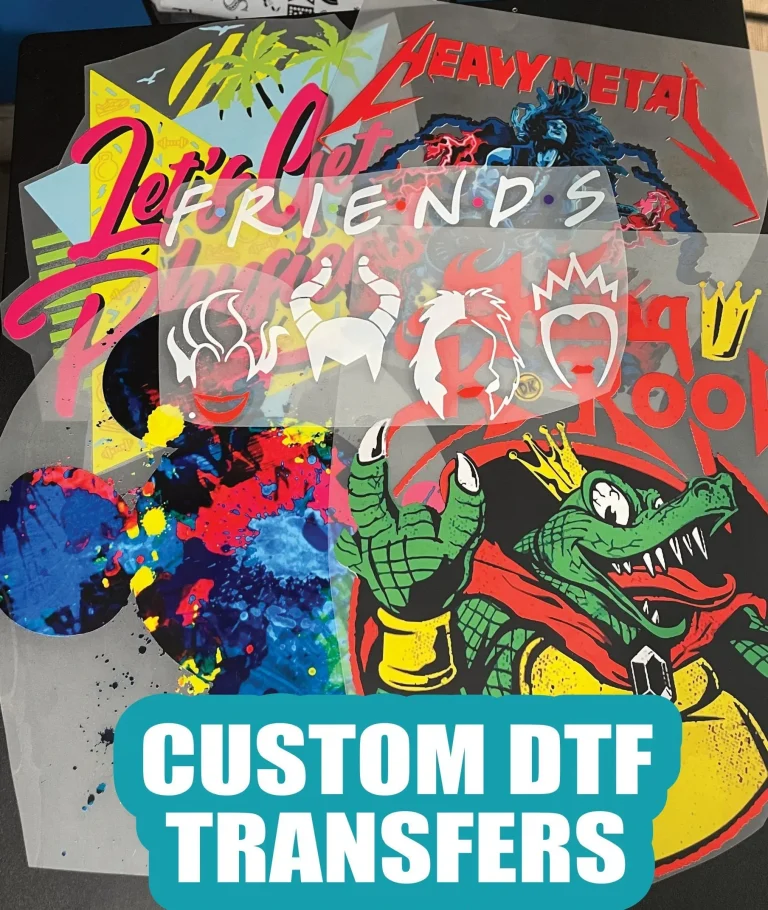

Understanding DTF Printing: A Comprehensive Overview

Direct-to-Film (DTF) printing has revolutionized how designs are transferred onto fabrics, providing a seamless solution suitable for all types of textiles. This printing method allows for stunning visuals with precise detail, making it ideal for intricate designs that other techniques, such as screen printing, may struggle to deliver. DTF printers utilize specialized inks that bond well with a variety of fabric types, including cotton, polyester, and blends, ensuring high-quality results regardless of the material. Such capability enhances the designer’s scope for creativity, enabling the development of unique products tailored to market demands.

Moreover, DTF printing’s ease of use cannot be overstated. The process involves printing onto a film, which is then applied to the garment using heat and pressure. This workflow is not only straightforward but also minimizes the risk of errors common in traditional methods, further affirming DTF printing as a preferred choice among textile printers. In an industry increasingly driven by innovation, understanding the mechanics and potential of DTF printing sets the foundation for more informed decision-making.

Advantages of DTF Transfers: Unlocking New Possibilities

The advantages of DTF transfers extend far beyond exceptional print quality; they revolutionize the way businesses approach textile printing. One of the standout benefits is their versatility—DTF transfers can effortlessly be applied to various fabric types, offering an expansive canvas for creative expression. Whether it’s for t-shirts, sportswear, or home textiles, DTF technology provides consistent, vibrant results that speak volumes about the quality of craftsmanship. This characteristic allows brands to maintain a diverse product range, appealing to different consumer preferences in today’s fashion landscape.

Furthermore, DTF transfers enable businesses to respond quickly to market trends due to their quick turnaround times. Orders that require custom prints can be fulfilled rapidly, thereby enhancing customer satisfaction and loyalty. For businesses that thrive on just-in-time manufacturing, the adaptability and efficiency of DTF printing offer a significant competitive edge, allowing them to pivot swiftly in response to consumer demand.

The Eco-Friendly Edge of DTF Printing

Today’s consumers are increasingly mindful of environmental sustainability, pushing businesses to adopt eco-friendly practices. DTF printing stands out in this regard, as many DTF processes utilize water-based inks and environmentally conscious materials. This shift not only aligns with global sustainability goals but also resonates well with eco-conscious consumers seeking brands that prioritize the planet. By choosing DTF transfers, companies can appeal to this growing demographic, enhancing their brand’s reputation and loyalty.

Moreover, the reduction of waste associated with the DTF printing process contributes to its eco-friendly profile. Traditional printing methods can often lead to significant material waste during setup and production. In contrast, DTF printing minimizes ink and material usage, aligning profitability with ecological responsibility. This dual advantage allows businesses to thrive financially while also playing their part in conserving the environment.

High-Quality Textile Printing: DTF’s Performance Standards

When it comes to high-quality textile printing, DTF transfers deliver unmatched precision and detail. The printing process ensures vibrant, true-to-design colors that consistently produce outputs that meet or exceed industry standards. This high fidelity reflects positively on brands, presenting a polished image that captivates consumers and builds confidence in product quality. Additionally, DTF printed designs showcase excellent durability, remaining vibrant even after numerous washes, making them an attractive option for apparel manufacturers.

The ability of DTF transfers to print intricately detailed images allows designers to unleash their creativity without compromising on quality. From fine lines to bold graphics, DTF technology guarantees a rich visual experience that can set any apparel apart in a crowded marketplace. This quality assurance encourages repeat business and fosters brand loyalty, as customers become advocates for products that are beautifully made and notably durable.

Cost-Effective Printing Solutions with DTF Technology

Cost-effectiveness is a pressing concern for many businesses, and DTF transfers provide a compelling solution. The lower setup costs associated with DTF printing compared to traditional methods make it a viable option for small businesses and entrepreneurs looking to manage their budgets effectively. Furthermore, the reduction in ink and material waste translates into significant cost savings, allowing businesses to increase profit margins while still delivering high-quality products to their customers.

In addition, the scalability of DTF printing operations allows businesses to manage their production levels efficiently. Whether it is a small batch for a specific event or large orders for retail distribution, DTF technology adapts effortlessly. This flexibility is essential for companies looking to balance finances while also meeting consumer demands, making DTF printing a smart, strategic choice in today’s dynamic market.

Recent Innovations in DTF Printing Technology

The landscape of DTF printing is continuously evolving, with several recent innovations pushing the technology’s capabilities further. New advancements in printer technology and ink formulation have significantly enhanced both productivity and reliability, enabling printers to produce complex designs faster and with greater fidelity. Such improvements keep DTF printing at the forefront of modern textile solutions, supporting a robust market growth driven by demand for custom apparel.

Furthermore, collaborations among industry players have led to the development of improved adhesion technologies, enhancing the durability and wash resistance of DTF prints. These innovations ensure that businesses can confidently offer their products to customers, knowing they will withstand the test of time. As the DTF printing market continues to expand, staying updated with these advancements is critical for businesses aiming to leverage this powerful printing method effectively.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then heat-pressed onto fabric. This technique allows for vibrant and high-quality prints suitable for various materials, making it an excellent choice for custom apparel and textiles.

What are the advantages of DTF printing over traditional methods?

The advantages of DTF printing include high print quality, cost-effectiveness, and versatility across materials. DTF transfers produce intricate designs with stunning color accuracy, require less setup and materials compared to traditional methods, and can be applied to a wide range of fabrics.

Is DTF printing an eco-friendly option?

Yes, DTF printing can be an eco-friendly printing solution. Many DTF processes utilize water-based, eco-friendly inks, significantly reducing environmental impact. This aligns with the growing consumer demand for sustainable practices in the textile industry.

Can DTF transfers be used on all types of fabrics?

DTF transfers are versatile and can be applied to various types of fabrics, including cotton, polyester, and specialty blends. This adaptability allows designers to experiment with different materials without compatibility concerns.

How does DTF printing ensure high-quality textile printing?

DTF printing provides high-quality textile printing by producing detailed images with vibrant colors. The technology is specifically designed to deliver durability, ensuring that prints remain intact and visually appealing even after multiple washes.

What makes DTF transfers a cost-effective printing solution?

DTF transfers are considered cost-effective due to lower setup costs and reduced ink and material use compared to traditional screen printing. This is especially beneficial for small runs and custom orders, maximizing creativity while minimizing production costs.

| Key Benefit | Description |

|---|---|

| High Print Quality | Produces vibrant, detailed images with excellent color accuracy and durability, ideal for intricate designs. |

| Versatility Across Materials | Can be applied to various fabrics including cotton and polyester, enhancing creative possibilities. |

| Cost-Effectiveness | Lower setup costs and reduced waste make DTF a smart choice for small production runs. |

| Simplicity of Use | Streamlined workflow reduces the risk of errors and ensures consistent quality and efficiency. |

| Quick Turnaround | Faster printing process leads to quicker order fulfillment and improved customer satisfaction. |

| Environmental Considerations | Utilizes eco-friendly inks to reduce environmental impact, appealing to sustainability-conscious consumers. |

Summary

DTF Transfers are transforming the landscape of textile printing by offering exceptional advantages that cater to contemporary printing demands. High-quality output, versatility across various materials, cost-effectiveness, ease of use, quick turnaround times, and environmental considerations are just a few highlights of this innovative printing method. As businesses and consumers increasingly prioritize personalization and sustainability, DTF Transfers present an unmatched opportunity to meet these rising expectations in the garment printing industry. Embracing this technology can not only enhance production efficiency but also elevate design possibilities, ensuring your projects shine in a competitive market.