In the world of custom merchandise, **DTF transfers** have quickly become a game-changing innovation. This cutting-edge printing method, known as Direct to Film (DTF) printing, allows businesses to create stunning visuals that pop on a variety of fabrics. With DTF transfer technology, companies can produce unique designs that capture attention and enhance merchandise offerings like never before. As competition grows, the demand for high-quality products and personalized experiences drives entrepreneurs to explore DTF solutions for their custom apparel needs. In this guide, we’ll delve into the many advantages of DTF printing and how it can elevate your brand in today’s market.

When it comes to modern printing techniques, the use of film-based transfers has revolutionized how businesses approach custom products. Often referred to as Direct-to-Film (DTF) technology, this innovative method empowers creators to showcase their artistic flair on various materials, unlocking new opportunities for brand promotion. By embracing DTF printing, businesses can produce vibrant imagery that resonates with consumers, enhancing the overall appeal of their merchandise. This approach not only supports unique apparel creation but also integrates seamlessly with the growing trend of personalized branding, making it essential for standing out in a crowded marketplace. Join us as we explore the exciting world of film transfers and their impact on the merchandise industry.

Understanding DTF Transfers and Their Impact on Custom Merchandise

Direct to Film (DTF) transfers have revolutionized the way custom merchandise is created and marketed. This innovative technology allows for intricate designs to be printed on a special film, which is then heat transferred onto various fabrics. By utilizing high-quality inks and advanced curing techniques, DTF printing ensures that designs maintain their vibrancy and detail, even after multiple washes. Businesses leveraging DTF for custom apparel can produce one-of-a-kind items that appeal to consumers seeking individuality in their fashion choices.

Moreover, DTF technology enables small businesses to compete with larger brands by offering personalized merchandise that reflects current trends. The flexibility of DTF transfers allows for the production of small to medium sized runs, making it feasible for entrepreneurs to experiment with different markets and customer bases. As the demand for unique and tailored clothing rises, understanding DTF transfers becomes essential for those looking to enhance their merchandise and establish a distinct presence in the marketplace.

The Process Behind DTF Printing: How it Works

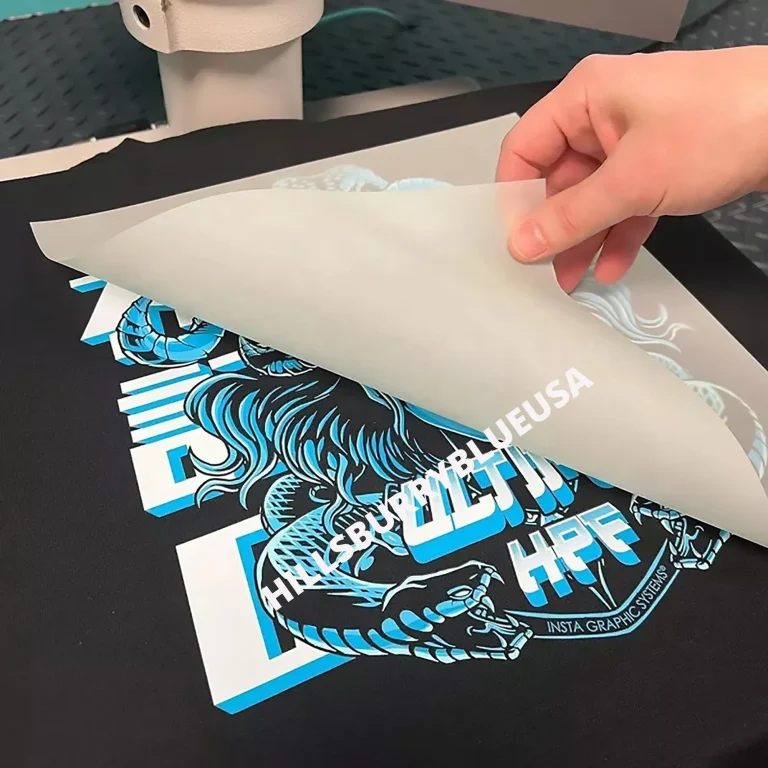

The DTF printing process is both straightforward and efficient, contributing to its growing popularity among businesses. It starts with digitally printing the desired design onto a PET film using specialized DTF printers. After that, an adhesive powder is applied to the still-wet ink, which is then cured with heat. This step is crucial as it ensures that the adhesive will bond effectively during the final transfer to fabric. Once cured, the film is positioned on the chosen material, and heat and pressure from a heat press finalize the transfer process, resulting in a durable and vivid design.

This method stands out because it allows for an array of prints to be prepared and stored for future applications, streamlining operations for those producing custom merchandise. The ability to print multiple designs on a single film and then apply transfers as needed maximizes efficiency and minimizes waste, making DTF printing a savvy choice for businesses aiming to enhance their product offerings. As recent advancements in DTF technology continue, its operational simplicity promises to open new avenues for creative expression in merchandise.

Key Advantages of DTF Transfers for Merchandising

One of the standout features of DTF transfers is their high-quality output. The technology not only captures intricate details but also produces vibrant colors that can bring designs to life on fabrics. This high level of color accuracy and detail is paramount for businesses aiming to leave a lasting impression on their customers. Whether creating promotional items or bespoke apparel, DTF technology assures that the final products meet the expectations of discerning consumers, enhancing both brand reputation and customer satisfaction.

In addition to superior print quality, DTF transfers provide remarkable versatility in materials. They can be applied to a variety of fabrics including cotton, polyester, and even leather. This adaptability means that businesses can venture into a wide range of product designs, from casual apparel to accessories and promotional materials. Such versatility empowers brands to cater to changing consumer tastes and seasonal trends, ensuring that their merchandise remains relevant and appealing throughout the year.

Current Trends in DTF Transfers: Personalization and Sustainability

The current landscape of DTF printing is characterized by a significant push towards personalization and sustainability in merchandise production. Consumers are increasingly drawn to products that reflect their individual tastes, and DTF transfers allow businesses to customize items in ways that traditional methods simply cannot match. This capability has led to a surge in demand for personalized gifts, apparel, and promotional items, positioning DTF as an essential technology for modern retailers determined to enhance their product lines.

Moreover, the emergence of eco-conscious consumerism has prompted many businesses to adopt sustainable practices in their printing processes. With water-based inks and minimal waste production, DTF technology aligns well with growing environmental advocacy. Companies that promote their use of more sustainable printing methods not only attract the eco-friendly consumer but also build a positive brand image. In an era where consumers are more informed about their purchasing choices, embracing sustainability can significantly enhance a business’s appeal and market share.

Applications of DTF Transfers in Various Merchandise

DTF transfers have become a go-to solution for a variety of merchandise applications, with custom apparel being at the forefront. Businesses can create branded shirts, hoodies, and even sportswear that showcase unique designs, logos, or messages tailored to target audiences. This versatility not only serves to engage existing customers but also draws in new clientele looking for quality and originality in their clothing choices.

Beyond apparel, DTF transfers are gaining traction in the creation of promotional items, such as tote bags, caps, and other merchandise bearing company branding. DTF technology easily adapts to these different product types, allowing companies to seamlessly integrate their logos and designs. Additionally, personalized gifts, such as decorative cushions or custom decals, can be produced with ease, making DTF a favored option for businesses looking to diversify their product offerings and enhance customer satisfaction.

Exploring Expert Resources for Mastering DTF Transfers

For businesses and entrepreneurs seeking to dive deeper into DTF printing, numerous expert resources are available that offer guidance on techniques, best practices, and equipment choices. Websites such as Printful provide extensive information on the DTF process, breaking down everything from initial setup to advanced strategies that can optimize product quality and production efficiency. Their comprehensive guides make it easier for newcomers to grasp the essentials of DTF transfers and successfully navigate the world of custom merchandise.

Likewise, companies like Brother offer insights into the benefits and applications of DTF printing technology, catering specifically to small business owners looking to enhance their offerings. Regular publications and platforms such as T-Shirt Magazine also publish valuable articles that explore emerging trends, share success stories, and provide tips for mastering DTF transfer techniques. These resources can be instrumental for those wanting to implement DTF technology effectively and carve out a niche in the competitive merchandise market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern printing technique where designs are printed onto a special film. Using heat and pressure, these designs are then transferred onto fabrics. This technology is popular for producing high-quality, colorful images on various materials, making it a versatile option for enhancing merchandise.

What advantages do DTF transfers offer for custom merchandise?

DTF transfers provide several advantages for custom merchandise, including high-quality output with vibrant colors and intricate details, compatibility with a wide range of fabrics, ease of use for in-house production, and cost-effectiveness for small batch runs. This makes DTF technology an appealing choice for entrepreneurs looking to enhance their product offerings.

Can DTF printing be used on all types of fabrics?

Yes, DTF printing is compatible with various fabrics, including cotton, polyester, and blends. This material versatility allows businesses to experiment with different products, from t-shirts to tote bags, making it an exceptional method for creating diverse custom merchandise.

How does DTF transfer technology compare to other printing methods?

DTF transfer technology stands out due to its ability to produce high-quality, detailed designs compared to traditional methods like screen printing or vinyl transfers. DTF offers better flexibility for small and large orders, easier setup for in-house production, and minimizes waste, making it a cost-effective solution for enhancing merchandise.

What current trends are influencing the use of DTF transfers?

Recent trends in DTF transfers include a rise in demand for personalized custom merchandise and a growing interest in sustainable printing practices. Many businesses are integrating eco-friendly solutions into their DTF printing processes, appealing to consumers who value sustainability while enhancing their product offerings.

Where can I learn more about DTF printing and its applications in merchandise?

There are various resources available to learn about DTF printing. Websites like Printful offer guides on DTF techniques, equipment, and best practices, while Brother provides insights on the benefits of DTF for small businesses. Additionally, T-Shirt Magazine covers emerging trends and success stories in the DTF transfer technology space.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Modern printing technique where designs are printed on a film and then transferred to fabric using heat. |

| Advantages | High-quality output, material versatility, ease of use, and cost-effectiveness. |

| Current Trends | Increased demand for personalized merchandise and sustainable printing solutions. |

| Applications | Custom apparel, promotional items, and personalized gifts. |

Summary

DTF transfers are revolutionizing the merchandise industry by enabling businesses to enhance their product offerings with vibrant and customizable designs. This innovative printing technology allows for intricate, high-quality images that can be applied to a diverse range of materials, catering to modern consumer preferences for personalization and sustainability. As businesses increasingly adopt DTF transfers, they can provide unique merchandise that not only stands out but also resonates with customers seeking distinct and eco-friendly options.